Water Filter bag

-

Product Advantages of Water Filter Bags: Superior Performance Making It the Industry’s First Choice

Water filter bags hold a pivotal position in the water treatment market and are highly favored by various industries. This is mainly due to a series of remarkable and unique product advantages they possess.High – efficiency Filtration Performance for Precise Water Purification

One of the core advantages of water filter bags is their outstanding filtration performance. According to different filtration requirements, it can accurately match filter cloths of various pore sizes, efficiently intercepting impurities ranging from large particles in millimeters to fine impurities in microns or even nanometers. For example, in industrial wastewater treatment, the wastewater from some metal processing industries often contains a large number of large – sized metal debris, sediment and other impurities, as well as micron – sized colloidal particles and bacteria and microorganisms generated by chemical reactions. By carefully selecting the appropriate pore – sized filter cloth, water filter bags can separate these impurities of different particle sizes one by one, making the treated. -

The wide application scenario of water filter bag: protect the water safety of various industries

With its excellent filtration performance, water filter bags have a wide range of applications in many fields, providing a strong guarantee for the water safety and production process in various industries.

In the field of drinking water treatment, water filtration bags are an important line of defense to ensure healthy drinking water for residents. When the water works purify the raw water, filter bags with different precision will be used to remove impurities such as sediment, algae, bacteria and some viruses in the water. After layers of filtration, the raw water meets the drinking water sanitation standards stipulated by the state before it is transported to thousands of households. For example, in some areas where the water source is polluted, by installing high-precision water filter bag equipment, harmful pollutants can be effectively removed from the water, so that residents can drink soothing water.

In industrial production, water filter bags play an irreplaceable role. In the electronics industry, the production process has very high requirements for water quality, and even extremely small impurities can affect the quality of electronic products. The water filter bag can accurately filter out the particles and microorganisms in the water, providing ultra-pure water for chip manufacturing, circuit board cleaning and other processes to ensure the stable performance of electronic products. In the chemical industry, a variety of chemical reactions require pure water as a raw material or reaction medium. The water filter bag can remove impurities and harmful ions in the water, prevent these substances from interfering with the chemical reaction, and ensure the quality of chemical products and the smooth progress of the production process.

In the field of environmental protection, water filter bags perform well in sewage treatment and rainwater collection and utilization. Sewage treatment plants use filter bags to pretreat sewage, remove large particles of impurities, and reduce the burden of subsequent treatment process. In the rainwater collection system, the filter bag can filter out the impurities such as leaves and dust in the rainwater, so that the collected rainwater can be used for non-drinking purposes such as irrigation and car washing, and realize the effective use of water resources.

In addition, in aquaculture, landscape fountains and other fields, water filtration bags also play an important role in maintaining the cleanliness and ecological balance of water bodies. It can be said that the application scenarios of water filter bags are extremely wide, and it is like a silent guardian to protect the quality of water in various industries. -

The working principle of water filter bag: the core mystery of efficient purification

In today’s era of pursuit of high-quality water resources, water filter bags, as a key filtration equipment, play a vital role. So, how is the water filter bag to achieve efficient filtration, so that the water quality is purified? There are many subtleties in how it works.

The water filter bag mainly removes impurities in the water by means of physical interception. It is usually made of a filter cloth of a specific material, which has different pore size specifications, from the micron level to the finer level. When the water containing impurities passes through the filter bag, particles, suspended solids, colloids and other impurities larger than the filter cloth aperture will be blocked by the filter cloth and cannot pass through, thus being trapped in the filter bag.

For example, in the treatment of industrial wastewater, the wastewater may contain a large number of metal particles, sediment, and suspended substances formed by various chemical substances. The water filter bag can accurately intercept these impurities, so that the filtered water meets the discharge standard or can be further treated and reused. In the swimming pool water treatment, the filter bag can effectively remove impurities such as hair, dander and dust brought by the human body, ensure that the pool water is clear and clean, and provide people with a safe and comfortable swimming environment.

In addition, the filtration effect of the water filter bag is also related to its structural design. Some filter bags adopt multi-layer structure, and the filter cloth aperture of different layers becomes smaller gradually, forming a gradient filtration mode. In this way, the water flow through the multi-layer filter cloth process, impurities will be gradually intercepted, greatly improving the accuracy and efficiency of filtration. Moreover, the material selection of the filter bag is also extremely critical, high-quality filter cloth material not only has good filtration performance, but also needs to have a certain strength and corrosion resistance to ensure stable operation in different water quality and working environment.

It is based on these physical interception, structural design and material characteristics and other factors, water filter bags can efficiently achieve water purification, becoming an indispensable water treatment equipment in many fields.

-

How the water filter bag works?

Working principle

The multi-bag filter introduces the water to be filtered into the filter shell through the pump, and the water enters the filter bag. Under the action of pressure, the water passes through the microhole of the filter bag, and the impurities are trapped in the filter bag, so as to achieve the filtration and purification of water.

Component introduction

Filter bag: Made of polypropylene, with different micron grades, such as 0.2 micron, 5 micron, 10 micron, 100 micron, can be selected according to filtration needs. The lower the micron number, the finer the particles that can be filtered out, and the higher the filtration accuracy.

Multi-bag filter: usually made of corrosion-resistant materials such as stainless steel, it can accommodate multiple filter bags to increase the filtration area and flow rate and improve filtration efficiency.

Material property

Polypropylene (PP) : good chemical stability, acid, alkali, organic solvent resistance; With good mechanical strength and wear resistance, the price is relatively low, cost-effective.

Polyethylene (PE) : strong chemical resistance, good flexibility, can adapt to a certain degree of deformation and vibration; Good low temperature resistance, can still maintain good performance in cold environment.

Polytetrafluoroethylene (PTFE) : has very high chemical stability, almost no reaction with any chemical substances; Excellent resistance to high temperature and low temperature; Smooth surface, not easy to absorb impurities, easy to clean.

Nylon (Nylon) : high strength, good toughness, can withstand greater pressure and tension; High filtration accuracy, can effectively remove fine particles and impurities in water. -

PP PE PTFE Nylon Water Filtration Multi Bag Filter Machine 0.2/5/10/100 Micron Polypropylene Liquid Filter Bag

In the delicate field of water filtration, our filter bags are well deserved experts. Using the scientific ratio of P, PE, PTFE, nylon multiple materials, combined with the precise aperture design of 0.2 to 100 microns, each polypropylene filter bag has been created by strict technology. From food and beverage production lines to pharmaceutical laboratories, from chemical raw materials purification to daily drinking water purification, it can accurately intercept all kinds of impurities in the water, efficiently remove microorganisms, colloids and fine particles, with excellent filtration performance, for your water safety and product quality layers of control, setting a new benchmark for industry quality.

vividness

Imagine that every drop of water is a small world, and our water filter bag is the magical guardian of this world. P, PE, PTFE, nylon interwoven into a tough and delicate “magic net”, polypropylene filter bag as with a sharp eye, whether it is 0.2 microns of tiny dust, or 100 microns of larger impurities, all do not want to escape its “pursuit”. When the water flows through the filter bag, it is like experiencing a wonderful purification journey, the impurities are stopped one by one, and the outflow of water becomes crystal clear, like a mountain spring, bringing you the purest water experience.

Affective resonance wind

Water is the source of life and the key to quality of life. We know your desire for pure water quality, so we have carefully developed this water filter bag. It is based on P, PE, PTFE and nylon, and is equipped with polypropylene filter bags of different microns to protect every water use. Whether it is the daily drinking water prepared for the family, or the safe choice of brewing milk powder for the child, it can ensure that the water quality is pure, so that you can drink every mouthful of water with confidence, every use of peace of mind, with pure water, nourish the happy life of you and your family. -

-

What is a water filter bag?

A water filter bag is a filtration device mainly used to remove impurities, suspended solids and other substances in water to purify water quality. The following is a detailed introduction:

Structure and Material

- Structure: Generally, a water filter bag is a bag-shaped structure with an opening at one end. The opening is usually designed with a ring or other fixing device for easy installation and connection to the water filtration system.

- Materials: It is often made of various filter materials such as polyester, polypropylene and nylon. These materials have different filtration precisions and chemical resistances to meet different filtration requirements. For example, polyester filter bags have good strength and chemical stability, while polypropylene filter bags are known for their excellent acid and alkali resistance.

Working Principle

- The water to be filtered enters the filter bag through the inlet. As the water passes through the filter material of the bag, impurities, suspended solids, and particulate matter in the water are trapped by the filter material due to the sieving and adsorption effects. The filtered water then passes through the filter bag and flows out through the outlet, thus achieving the purpose of water purification. The filtration precision of the filter bag can range from a few microns to hundreds of microns, depending on the specific application and the fineness of the filter material.

Applications

- Industrial Fields: In industrial water treatment, such as in the chemical, electroplating, and pharmaceutical industries, water filter bags are used to remove impurities in process water to ensure the quality of products and the normal operation of production equipment. They can also be used in industrial wastewater treatment to reduce the content of pollutants in the wastewater before it is discharged.

- Domestic Use: In household water purification systems, water filter bags are often used as the first stage of filtration to remove large particles of impurities, rust, and sediment in tap water, prolonging the service life of subsequent water purification equipment such as water purifiers and improving the quality of domestic water.

- Aquaculture: In aquaculture, water filter bags are used to filter pond water or circulating water in aquaculture systems to remove uneaten feed, fish feces and other impurities, maintaining good water quality and a suitable living environment for aquatic organisms.

- Swimming Pools: In swimming pool water treatment systems, water filter bags play a role in filtering out suspended matter, leaves and other impurities in the water to keep the pool water clean and clear and reduce the burden of disinfection and purification equipment.

-

Customized bleached cotton wound dust filter PP 1-200um

Customized bleached cotton wound dust filter PP 1-200um used to remove suspended solids in liquids acid and alkali resistance

AFC– filter cartridge bleached cotton 50 -200micron1- 3.5″ Dia. x 30″ L string wound filter cartridge with a tinned steel core. Bleached cotton string wound cartridges work well for potable liquids, vegetable oils, beverages, organic solvents and more. The bleached cotton is FDA acceptable under CFR title 21 for food and potable water contact. This 50 micron filter cartridge is double open ended (DOE) with no caps

-

High – Performance Liquid Filter Bags: Your Ideal Filtration Solution

High – Performance Liquid Filter Bags: Your Ideal Filtration Solution

In industrial and commercial liquid – handling processes, efficient filtration is not just a luxury but a necessity. Our liquid filter bags are engineered to meet and exceed the highest standards of filtration performance.

Product name: polyester filter bag

Filter material: polyester

Filter bag pressure: pressure difference ≤ 0.2MPa (replacement filter bag reference value)

Project

Skills Requirement

Detect

Determination

Gram weight (g/mg²)

500(±5%)

512

Qualified

Thickness (mm)

2.3(±5%)

2.35

Qualified

Air permeability

(L/m².s)

350-500(±25)

370

Qualified

Breaking Strength

(N)

warp

800(±2%)

803

Qualified

weft

1100(±2%)

1125

Elongation

warp

35(≤%)

34

Qualified

weft

50(≤%)

48

Temperature resistance(°C) ≤130(°C)

127°C

Qualified

Exterior No wrong warp, wrong weft, broken edges, smudges, scratches and holes

No wrong warp, wrong weft, broken edges, smudges, scratches and holes

Qualified

The fabric has passed the sanitary standard and testing standard:GB4806.7-2016

Processing technology: all seams, O- galvanized ring

PEΦ180*430*5UM 880 pcs

After passing the inspection, it will be given out of the factory and hereby certified.

Superior Filtration Precision

Available in a wide range of micron ratings, from ultra – fine to coarse filtration, our filter bags can effectively remove particles, impurities, and contaminants of various sizes. Whether it’s in the chemical, food and beverage, pharmaceutical, or water treatment industries, they ensure that your liquid products meet the strictest quality requirements.Exceptional Durability

Made from high – quality materials, these filter bags are designed to withstand the rigors of continuous use. They resist corrosion, abrasion, and chemical degradation, ensuring a long service life and reducing the frequency of replacement. This durability not only saves costs but also minimizes downtime in your production processes.Easy Installation and Maintenance

Our liquid filter bags are designed for quick and hassle – free installation. They fit seamlessly into most standard filter housings, allowing for easy integration into your existing filtration systems. Additionally, maintenance is a breeze. When the filter bag reaches the end of its service life, it can be easily removed and replaced, keeping your operations running smoothly.Cost – Effective Filtration

By providing high – quality filtration at a competitive price, our filter bags offer an excellent cost – performance ratio. Their long – lasting performance and easy maintenance contribute to overall cost savings, making them a smart investment for any business looking to optimize its filtration processes.Choose our liquid filter bags and experience the difference in filtration efficiency, durability, and cost – effectiveness. Contact us today to find the perfect filtration solution for your specific needs.

-

Nylon Filter bag

Technical Specification Sheet Product Name Nylon Filter bag Product Code UF6663-A Physical properties Materials 200 Micro Nylon Type 3 threads Stitch ways g/m² Top Width 3500mm Loss on Ignition (%) ≥10 Chemical Finish normal Air Permeability (L/m²S@200Pa) Density Warp (ROOT/INCH) Weft Tensile Strength Warp (N/25mm) Weft Temperature Continues temperature C° -10 to 50 Instant temperature Trading information trading information L... -

Nylon Filter bag UF6662-A

Technical Specification Sheet Product Name Nylon Filter bag Product Code UF6662-A Physical properties Materials 200 Micro Nylon Type 3 threads Stitch ways g/m² Top Width 570mm Loss on Ignition (%) ≥10 Chemical Finish normal Air Permeability (L/m²S@200Pa) Density Warp (ROOT/INCH) Weft Tensile Strength Warp (N/25mm) Weft Temperature Continues temperature C° -10 to 50 Instant temperature Trading information trading inf... -

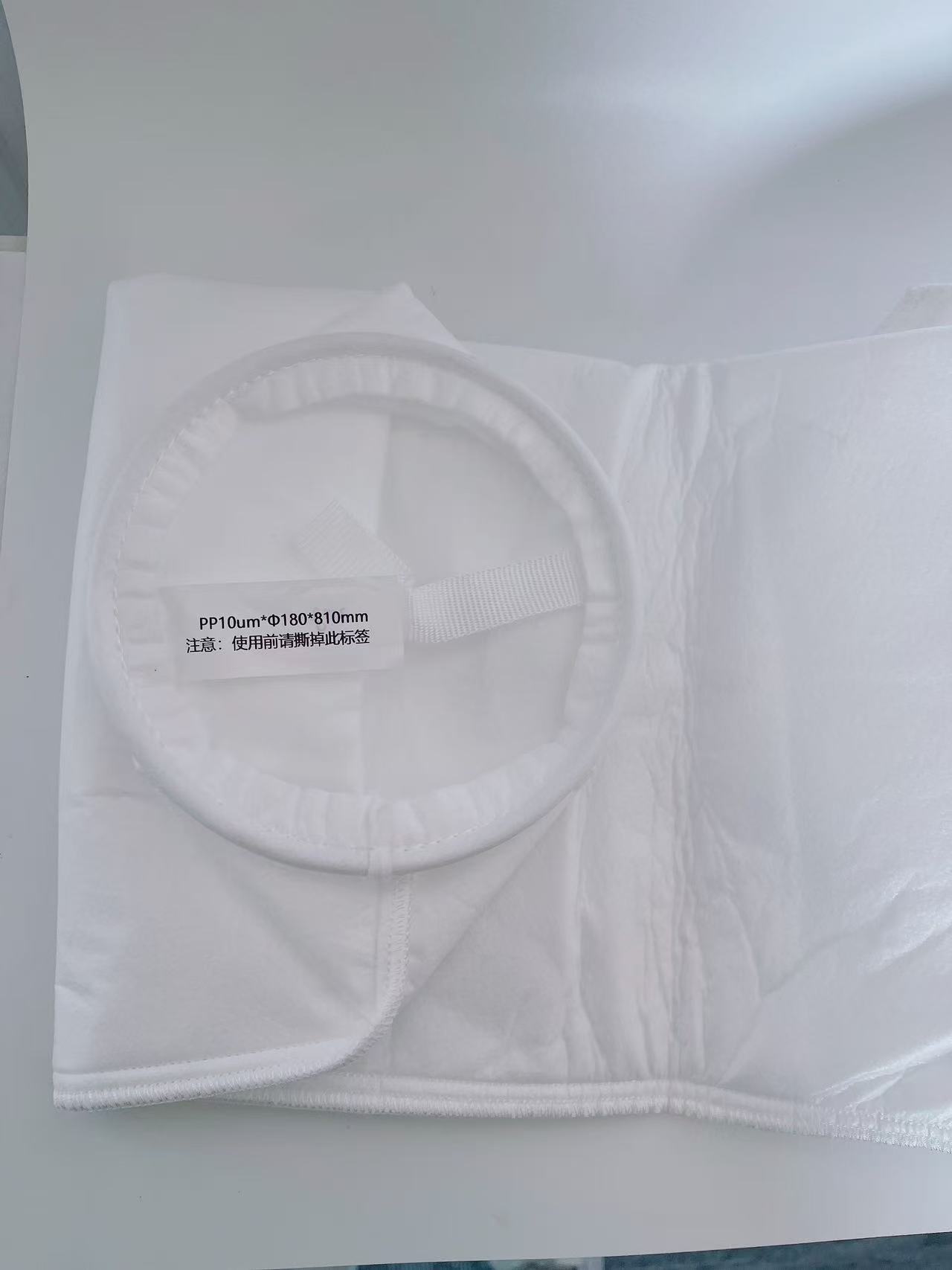

PE 10UM 180-810 polyester filter bag

PEΦ180*810*10UM Product name: polyester filter bag Filter material: polyester Filter bag pressure: pressure difference ≤ 0.2MPa (replacement filter bag reference value) Project Skills Requirement Detect Determination Gram weight (g/mg²) 370(±5%) 375 Qualified Thickness (mm) 2.1(±5%) 2.14 Qualified Air permeability (L/m².s) 600(±25%) 625 Qualified Breaking Strength (N) warp 800(±2%) 812 Qualified weft 1100(±2%) ...