Pulse Valve

-

Technical Analysis and Application of DMK – Z – 50 Electromagnetic Pulse Valve

The DMK – Z – 50 electromagnetic pulse valve is a key component in numerous industrial applications, especially those related to dust removal and pneumatic control. This article delves deeper into its technical aspects, installation requirements, maintenance considerations, and a comparison with similar products in the market.Technical Specifications

- Voltage Options: The DMK – Z – 50 offers a variety of voltage options to suit different power supply requirements. It can be configured to operate on 24 VDC, 110V AC, 120V AC, 220V AC, or 230V AC (50/60 Hz). This flexibility makes it compatible with a wide range of industrial electrical systems. For example, in a factory with a predominantly 220V AC power supply, the valve can be easily integrated without the need for complex voltage conversion systems.

- Connection Size: With a DN50 (G2”) inlet and outlet threaded port size, the valve is designed to handle a significant volume of compressed air. This size is suitable for applications where a relatively large – scale air flow is required, such as in large – capacity dust collectors or high – volume pneumatic conveying systems.

- Working Pressure Range: It has a working pressure range of 0.1 to 0.8 MPa. This wide pressure range allows the valve to be used in diverse industrial scenarios. In low – pressure applications like some food and beverage production lines where gentle air pulses are needed, the valve can operate effectively at the lower end of the pressure range. On the other hand, in more demanding applications such as heavy – duty mining dust collection, it can handle the higher pressures without performance degradation.

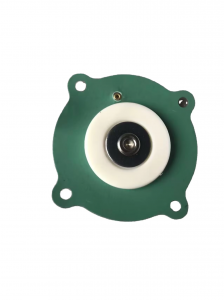

- Diaphragm Material: The diaphragm of the DMK – Z – 50 is typically made of NBR (Nitrile Butadiene Rubber). NBR is known for its excellent resistance to oil, fuel, and abrasion, which are common factors in industrial environments. This material choice ensures that the diaphragm can withstand the harsh conditions of continuous operation, resulting in a long – lasting and reliable valve.

Installation Guide

- Pre – installation Checks: Before installing the DMK – Z – 50, it is essential to check the valve for any visible damage that may have occurred during transportation. Inspect the body, diaphragm, and electromagnetic coil for any signs of cracks, dents, or loose parts. Also, ensure that all the necessary installation accessories, such as gaskets and mounting brackets, are present.

- Cleaning the Pipeline: The air supply pipeline should be thoroughly cleaned before installing the valve. Any debris, dirt, or moisture in the pipeline can cause damage to the valve’s internal components or affect its performance. Use compressed air or appropriate cleaning agents to remove any contaminants.

- Mounting the Valve: The valve should be mounted in a location that allows for easy access for maintenance and inspection. Ensure that the valve is installed in the correct orientation, with the inlet and outlet ports properly aligned with the pipeline. Use the provided mounting brackets and fasteners to securely attach the valve to the support structure.

- Electrical Connection: When connecting the electrical wires to the electromagnetic coil, follow the wiring diagram provided with the valve. Make sure that the electrical connections are secure and properly insulated. If the voltage is above 36V, it is recommended to ground the valve to ensure electrical safety.

Maintenance Tips

- Regular Inspection: Periodically inspect the valve for any signs of wear or damage. Check the diaphragm for cracks, tears, or signs of excessive wear. Inspect the electromagnetic coil for any overheating or electrical issues. Look for any air leaks around the valve body or connections.

- Cleaning: Clean the valve regularly to remove any accumulated dust, dirt, or debris. Use a soft brush or compressed air to clean the internal and external parts of the valve. This helps to maintain the valve’s performance and prevent clogging of the air passages.

- Diaphragm Replacement: If the diaphragm shows signs of significant wear or damage, it should be replaced promptly. The replacement process is relatively straightforward, but it is important to use a genuine replacement diaphragm to ensure proper fit and performance.

- Testing: Periodically test the valve’s operation to ensure that it is functioning correctly. Use a pulse control instrument to send electrical signals to the valve and check that it opens and closes properly. Monitor the air flow and pressure to ensure that they are within the specified range.

Comparison with Similar Products

- Response Time: Compared to some other electromagnetic pulse valves in the market, the DMK – Z – 50 offers a faster response time. This means that it can open and close more quickly in response to an electrical signal, which is crucial for applications that require precise timing of air pulses. For example, in a high – speed dust collection system where rapid cleaning of filter bags is essential, the fast response time of the DMK – Z – 50 can result in more efficient dust removal.

- Durability: Thanks to its high – quality materials and robust construction, the DMK – Z – 50 has a longer service life compared to some similar products. The use of NBR diaphragms and aluminum alloy bodies contributes to its durability, making it suitable for use in harsh industrial environments where other valves may fail prematurely.

- Energy Efficiency: The DMK – Z – 50 is designed to be energy – efficient, consuming less power during operation. This is an advantage over some older – style or less – efficient pulse valves, as it helps to reduce the overall energy consumption of the system and lower operating costs.

In summary, the DMK – Z – 50 electromagnetic pulse valve is a technically advanced and reliable product. By understanding its technical specifications, following proper installation and maintenance procedures, and comparing it with other products, industrial users can make informed decisions about its use in their specific applications, ensuring optimal performance and long – term reliability. -

DMK – Z – 50 Electromagnetic Pulse Valve: A High – Performance Solution

In the realm of industrial dust collection and pneumatic control systems, the DMK – Z – 50 electromagnetic pulse valve stands out as a reliable and efficient component. This valve plays a crucial role in ensuring the smooth operation of various industrial processes, especially those related to dust removal and pneumatic conveying.Design and Structure

The DMK – Z – 50 is designed with precision and durability in mind. Its body is typically made of high – quality aluminum alloy, which not only provides excellent corrosion resistance but also makes the valve lightweight yet sturdy. The internal structure features a diaphragm that is the heart of the valve’s operation. The diaphragm is crafted from a special rubber compound that can withstand high pressures and frequent cycling, ensuring a long service life.The valve is equipped with an electromagnetic coil. When an electrical signal is received, the coil generates a magnetic field that activates the valve. This design allows for quick and accurate control of the valve’s opening and closing, which is essential for efficient system operation.Working Principle

The working principle of the DMK – Z – 50 is based on the interaction between the electromagnetic coil and the diaphragm. In its normal state, the diaphragm seals the valve outlet, preventing the flow of compressed air. When the pulse control instrument sends an electrical signal to the electromagnetic coil, the coil energizes and creates a magnetic force. This magnetic force pulls the armature, which in turn opens the diaphragm.Once the diaphragm is opened, compressed air can flow through the valve at a high velocity. This sudden burst of air is used for various purposes, such as cleaning dust – laden filters in a dust collector. When the electrical signal from the control instrument stops, the electromagnetic coil de – energizes, and the diaphragm returns to its original position, closing the valve and halting the air flow.Performance Features

- Fast Response Time: The DMK – Z – 50 offers an extremely fast response time, typically within milliseconds. This rapid response is crucial for applications where precise timing of air pulses is required, such as in high – speed dust collection systems. For example, in a large – scale industrial dust collector, the quick opening and closing of the valve ensure that each filter bag is cleaned effectively in a short period.

- High Pressure Resistance: It can withstand a wide range of working pressures, usually from 0.1 MPa to 0.8 MPa. This high – pressure tolerance makes it suitable for use in different industrial environments, whether it’s a low – pressure pneumatic system in a food processing plant or a high – pressure application in a mining dust collection setup.

- Long – Lasting Durability: Thanks to its high – quality materials and robust construction, the DMK – Z – 50 has a long service life. The diaphragm, in particular, is designed to endure millions of cycles without failure. In a continuous – operation dust collection system in a cement factory, the valve can operate for years with minimal maintenance, reducing downtime and maintenance costs.

- Energy – Efficient Operation: The valve is designed to be energy – efficient. It only consumes power when the electromagnetic coil is activated to open the valve. Once the air pulse is completed, the coil de – energizes, saving energy. This energy – saving feature is not only environmentally friendly but also helps to reduce the overall operating costs of the system.

-

Significant Performance Advantages of DMF – ZM – 40 Pulse Valve

The DMF – ZM – 40 pulse valve is highly favored in industrial applications due to its series of remarkable performance advantages, which make it stand out among similar products.

From the perspective of sensitivity, the DMF – ZM – 40 pulse valve responds extremely quickly to the electrical signals of the pulse blower control instrument. As soon as the electrical signal is received, the moving core of the electromagnetichead can quickly move, opening the exhaust hole of the rear chamber, causing the diaphragm to rapidly move backward to achieve the blower action. The entire process is completed almost instantaneously. This high sensitivity ensures that the cleaning and blower actions can be carried out promptly and accurately, effectively avoiding the problem of insufficient dust removal due to delayed response, thereby ensuring the efficient operation of the dust collector.

In terms of exhaust volume, the DMF – ZM – 40 pulse valve has outstanding performance. Its design structure enables it to provide a large exhaust channel when in the open state, allowing compressed air to be rapidly and in large quantities ejected through the valve outlet. The powerful blower airflow can forcefully impact the dust on the surface of the filter bag, completely removing it, even the stubbornly adhered dust is difficult to resist. Compared with some similar products, it can complete the dust removal of the same area filter bag in a shorter time, greatly improving the dust removal efficiency and reducing the maintenance time and cost of the equipment.The working stability is also a major highlight of the DMF – ZM – 40 pulse valve. It is manufactured with high-quality materials, such as the diaphragm using imported nitrile rubber, which has good flexibility and wear resistance, capable of withstanding frequent opening and closing actions, ensuring that it will not crack or damage during long-term use. At the same time, its internal structure has been carefully designed, with a close and reasonable fit between each component, maintaining a stable working state under different working environments and pressure conditions. Whether in harsh environments with high temperature and high humidity, or under high pressure and high-frequency blower operation intensity, the DMF – ZM – 40 pulse valve can operate reliably, providing a strong guarantee for the continuity of industrial production.

In addition, the DMF – ZM – 40 pulse valve also has great convenience in installation, use, and maintenance. It has fixed nuts for installation at both the inlet and outlet ends, making the installation connection between the air box and the dust collector blower pipe simple and quick, effectively shortening the installation time. During use, its working principle is simple and easy to understand, and the operating state is easy to monitor and control. When maintenance is needed, due to its reasonable structure design, each component is easy to disassemble and replace, allowing maintenance personnel to quickly locate and solve problems, reducing the difficulty and downtime of equipment maintenance and improving the production efficiency of the enterprise.

-

The wide range of applications for the DMF – ZM – 40 pulse valve

The DMF – ZM – 40 pulse valve, with its outstanding performance, has extensive and crucial applications in numerous industrial fields, becoming an important component for ensuring the production environment and equipment operation.

In the field of dust removal, especially in the pulse bag-type dust collector system, the DMF – ZM – 40 pulse valve is regarded as the core component. As the “switch” of the dust cleaning blow-off system’s compressed air, it is precisely controlled by the pulse blow-off controller’s output signal, and it performs dust cleaning by blowing on the filter bags row by row (section by section). In boiler dust collectors, it can promptly remove a large amount of dust generated during boiler operation, preventing dust accumulation from affecting the thermal exchange efficiency and safe operation of the boiler; in medium-frequency electric furnace dust collectors, in the presence of high-temperature and high-concentration dust environment, the DMF – ZM – 40 pulse valve can still work stably, ensuring the air quality in the electric furnace workshop and protecting the health of workers. Moreover, in various dust removal equipment such as casting-specific dust collectors, woodworking-specific dust collectors, and mining-specific dust collectors, its busy “presence” can be seen, creating a clean environment for industrial production.

In environmental protection waste gas treatment, the DMF – ZM – 40 pulse valve also plays an important role. For example, in plasma waste gas purification equipment and spray towers, it participates in the waste gas treatment process. By controlling the blow-off of compressed air, it assists the purification equipment in capturing and separating pollutants in the waste gas, improving the waste gas purification efficiency, and helping enterprises meet environmental protection emission standards and reducing pollution to the atmospheric environment.In some industrial production processes that require precise control of gas flow and pressure, the DMF – ZM – 40 pulse valve also performs well. For instance, in chemical production, certain reaction processes require precise control of the gas addition amount and time intervals. The DMF – ZM – 40 pulse valve can accurately open and close according to the set program, providing stable gas supply conditions for chemical reactions, ensuring the smooth progress of chemical production and the stability of product quality.

-

In-depth Analysis of the Working Principle of DMF – ZM – 40 Pulse Valve

In industrial dust removal systems, the DMF – ZM – 40 pulse valve plays a crucial role, and its efficient and stable operation relies on a unique and ingenious working principle.

From a structural perspective, the DMF – ZM – 40 pulse valve is mainly divided into two gas chambers by a diaphragm. When the entire system is connected to compressed air, the compressed air will slowly enter the rear gas chamber through the throttle hole. At this time, the pressure in the rear gas chamber gradually increases until it tightly presses the diaphragm assembly against the output port of the valve, thus putting the electromagnetic pulse valve in the initial “closed” state, like a meticulous guard, firmly controlling the flow of compressed air.

When the pulse blowing control instrument sends an electrical signal, this signal is like giving the pulse valve an “open” instruction. The electrical signal causes the armature of the electromagnetic pulse valve to move rapidly backward, thereby opening the exhaust hole of the rear gas chamber. The air in the rear gas chamber is rapidly expelled in a short period of time, and the pressure instantly drops. Under the action of the pressure difference, the diaphragm assembly moves backward, and the compressed air that was previously blocked rushes out through the valve output port at high speed. At this time, the electromagnetic pulse valve enters the “open” state, and the powerful blowing airflow cleanses the filter bag, blowing off the dust adhering to the surface of the filter bag, ensuring the efficient operation of the dust removal system.

When the electrical signal from the pulse blowing control instrument disappears, the armature of the electromagnetic pulse valve returns to its initial position under the action of the reset device, and the exhaust hole of the rear gas chamber closes. The rear gas chamber then begins to intake air through the throttle hole, and the pressure gradually rises. The diaphragm assembly re-contacts the output port of the valve again, and the electromagnetic pulse valve returns to the “closed” state, waiting for the next blowing command to arrive. This precise and efficient working mode enables the DMF – ZM – 40 pulse valve to operate stably in the dust removal and blowing system of the pulse bag dust collector, continuously contributing to the purification of industrial production environments.

-

DMF-Z-50: The Vanguard of Dust Removal in Technological Innovation and Industry Practice

In the wave of pursuing high efficiency and environmental protection in the industrial dust removal field, DMF-Z-50 has become the top choice for numerous enterprises with its outstanding performance. From technological breakthroughs to practical applications, it is redefining the standards of industrial dust removal as an innovator.

I. In – depth Analysis of Core Technical ParametersThe core technical parameters of DMF-Z-50 are the foundation of its high efficiency. With a diameter of 50mm, this size design enables it to be compatible with the pipelines of various specifications of dust removal equipment, ensuring the efficient transmission of compressed air. The working pressure range is usually 0.4 – 0.8MPa. This wide pressure adaptation range allows DMF-Z-50 to maintain stable blowing even in low-pressure environments and achieve strong power output under high-pressure requirements.In terms of electrical performance, DMF-Z-50 supports multiple voltage specifications, commonly including DC24V, AC220V, etc., meeting the power supply needs of different industrial scenarios. Its response time is extremely short, only taking dozens of milliseconds. This means that after the dust removal system issues an instruction, it can complete the blowing action instantly, greatly improving the dust removal efficiency. In addition, the service life of this pulse valve can reach more than millions of times. Even under high-frequency usage conditions, it can still maintain stable performance.II. Common Faults and Efficient Troubleshooting SolutionsAlthough DMF-Z-50 has stable performance, faults may still occur after long-term use. One of the most common problems is that the pulse valve fails to open normally. This may be caused by a burned-out electromagnetic coil, a short circuit in the control circuit, or a blocked air path. When troubleshooting, first check the resistance value of the electromagnetic coil. If the resistance value is abnormal, the coil needs to be replaced. At the same time, carefully check whether there are any damages or poor contacts in the control circuit. For the air path, clean the impurities and accumulated water in the pipeline to ensure smooth air flow.Another common fault is air leakage, which is mostly caused by the aging of the diaphragm and the wear of the seals. The leakage position can be preliminarily determined by observing whether there are sounds and traces of gas leakage around the valve. Once the diaphragm or seals are found to be damaged, they should be replaced with original factory accessories in a timely manner to ensure the sealing performance. In addition, regularly conducting pressure tests and tightness inspections on the pulse valve can effectively prevent faults and extend the service life of the equipment.III. Typical Industry Application CasesIn the cement production industry, after a large-scale cement plant introduced DMF-Z-50 pulse valves for bag dust collectors, the dust removal efficiency increased significantly. Before the transformation, the blowing force of traditional pulse valves was insufficient, resulting in serious dust accumulation on the filter bags, and the dust removal efficiency could only be maintained at around 85%. After adopting DMF-Z-50, its powerful blowing ability enabled thorough cleaning of the filter bags, and the dust removal efficiency soared to over 99%, effectively reducing dust emissions and meeting environmental protection standards. At the same time, its long service life reduced the equipment maintenance frequency, saving more than 300,000 yuan in maintenance costs annually.In the steel smelting industry, the harsh environment with high temperature and high dust content poses a great challenge to the performance of pulse valves. A steel enterprise applied high-temperature-resistant DMF-Z-50 pulse valves in electric-bag composite dust collectors. Even in an environment with a temperature of over 200°C, they still operated stably. The precise air flow control of these pulse valves ensured the stable air flow in the electric field and filter bag areas of the dust collector, greatly improving the dust collection efficiency and helping the enterprise achieve green production.With its precise technical parameter design, reliable performance, and successful practices in various industries, DMF-Z-50 has become a core component in the industrial dust removal field. Whether in technological innovation or practical applications, it demonstrates strong competitiveness and provides a solid guarantee for the environmental protection upgrade of industrial production. With the continuous progress of technology, DMF-Z-50 is bound to play an even greater role in more fields. -

DMF-Z-50: Key Electromagnetic Control Component of Industrial Dust Collector

In numerous stages of industrial production, the control of dust pollution is of vital importance. The industrial dust collector, as the core equipment to solve this problem, requires the coordinated work of many precise components for its efficient operation. DMF-Z-50 is one of the key electromagnetic control components.

I. In-depth Analysis of Working Principle

The DMF-Z-50 pulse valve mainly relies on the magnetic field generated by the electromagnetic coil to precisely control the valve’s action, thereby achieving efficient on-off operation of the airflow. When the electromagnetic coil is energized, the instantaneous magnetic field will attract the valve core to move upward, and the originally closed air passage channel will immediately open. Compressed air can then flow smoothly through, providing necessary power support for the subsequent dust removal process. When the electromagnetic coil is de-energized, the valve core, under the strong elastic force of the spring, quickly moves downward, and the air passage channel is closed again. The entire process is seamless and extremely rapid.

From its internal structure, the diaphragm ingeniously divides the electromagnetic pulse valve into two gas chambers, the front and the rear. In the initial state, after the compressed air is connected, the compressed air will slowly enter the rear gas chamber through the carefully designed throttle hole. At this time, the pressure in the rear gas chamber rises rapidly, and the strong pressure tightly presses the diaphragm assembly against the output port of the valve, keeping the electromagnetic pulse valve in a “closed” state, ensuring that the gas does not leak. When the system equipment sends out a precise pulse signal, the armature of the electromagnetic pulse valve will quickly move backward, and the exhaust hole in the rear gas chamber opens instantly. The gas in the rear gas chamber is rapidly discharged in a very short time, and the pressure drops sharply. Due to the lack of support from the rear gas chamber pressure, the diaphragm assembly moves backward rapidly under the pressure of the front compressed air, allowing the compressed air to flow through the valve output port powerfully. At this time, the electromagnetic pulse valve is in the “open” state, efficiently completing the blowing task. When the pulse signal disappears, the armature of the electromagnetic pulse valve is quickly reset by the return spring, and the exhaust hole of the rear gas chamber closes. The pressure in the rear gas chamber begins to rise again, and the diaphragm assembly again closely adheres to the output port of the valve. The electromagnetic pulse valve returns to the “closed” state, preparing for the next blowing.

II. Widespread Application Areas

The DMF-Z-50 pulse valve holds a crucial position in the industrial dust collector system and is widely used in various bag-type dust collectors and electrostatic dust collectors, etc. In bag-type dust collectors, its main responsibility is to provide high-pressure pulse gas during the dust removal process. As industrial production continues, the filter bags will gradually accumulate a large amount of dust particles, which will seriously affect the ventilation effect and dust removal efficiency of the dust collector. At this time, the DMF-Z-50 pulse valve, according to the preset program, periodically sprays high-pressure pulse gas onto the filter bags. The powerful airflow can instantly blow off the dust particles on the filter bags, allowing them to regain their good filtering performance, thus ensuring that the dust collector is always in an efficient operating state and continuously purifies industrial waste gas.

In electrostatic dust collectors, the DMF-Z-50 pulse valve also plays an indispensable role. It can precisely control the airflow within the electrostatic dust collector, ensuring a stable and uniform airflow distribution in the electric field area. Stable airflow helps to improve the dust capture efficiency of the electrostatic dust collector, allowing the dust in the industrial waste gas to be more effectively adsorbed and collected, further enhancing the performance and stability of the entire dust removal system.

III. Outstanding Product Features

High efficiency and energy saving: The DMF-Z-50 pulse valve adopts advanced design concepts and cutting-edge technologies, ensuring strong blowing capacity while significantly improving energy utilization efficiency. It can quickly respond to the pulse signals sent by the system, precisely control the on-off and flow rate of the airflow, and avoid unnecessary waste of energy. In practical industrial applications, compared with traditional pulse valves, it can significantly reduce energy consumption and save a large amount of operating costs for enterprises.

High durability: This pulse valve is extremely meticulous in material selection, using high-quality materials for manufacturing. These materials have excellent corrosion resistance and wear resistance, and can operate stably and continuously in harsh industrial environments. Whether facing high temperatures, high humidity environments, or industrial exhaust gases containing corrosive gases, the DMF-Z-50 pulse valve can always maintain good performance, and its service life is much longer than similar products, greatly reducing the frequency of equipment maintenance and replacement, and providing a strong guarantee for the continuous production of enterprises.

Easy installation: Its structural design is simple and clear, and the installation and disassembly of each component are very simple. During the actual installation process, workers do not need complex tools and professional skills to complete the installation task quickly. This simple and convenient installation method not only saves installation time and labor costs, but also makes it easy to perform maintenance and replace parts of the equipment in the later maintenance and maintenance process, improving the maintenance efficiency of the equipment.VII. Precautions during use

Power matching is crucial: When using the DMF-Z-50 pulse valve, it is necessary to ensure that the connected power voltage is exactly the same as the rated voltage of the electromagnetic coil. If the power voltage is too high, it may cause the electromagnetic coil to overheat and burn out; while if the power voltage is too low, the pulse valve will not work properly, affecting the performance of the entire dust removal system. Therefore, during the installation and debugging of the equipment, it is necessary to carefully check the power parameters to ensure that they are consistent with the requirements of the pulse valve.

Sealing components should be inspected regularly: The sealing components are the key components to ensure the sealing performance of the pulse valve. During long-term use, the sealing components may become loose due to wear and aging, resulting in leakage of gas and affecting the normal operation of the pulse valve. Therefore, regular inspections of the status of the sealing components are necessary. If the sealing components are severely worn, they should be replaced in time to ensure that the valve always has good sealing performance and maintains the efficient operation of the dust removal system.

Selection for high-temperature environments: If the DMF-Z-50 pulse valve needs to work in a high-temperature environment, a special high-temperature pulse valve must be selected. Ordinary pulse valves may have changes in internal material properties in high-temperature environments, causing the valve to fail to open and close properly, or even be damaged. While high-temperature pulse valves use materials resistant to high temperatures and special structural designs to effectively resist the influence of high-temperature environments, ensuring stable and reliable operation in high-temperature conditions.

In conclusion, the DMF-Z-50 pulse valve, with its unique working principle, wide application fields, outstanding product features, and clear usage precautions, plays an irreplaceable important role in industrial dust removal system. It not only provides an efficient and stable dust treatment solution for industrial production, but also has significant advantages in energy conservation and environmental protection, as well as reducing enterprise operating costs. It is one of the important forces promoting industrial sustainable development. -

DMF-Z-40 Pulse Valve:Technical Parameters

Technical Parameters

- Working Pressure: The working pressure range of this pulse valve is 0.4 – 0.7Mpa. Within this pressure range, it can operate stably, providing sufficient and stable blowing power for the dust removal system. The appropriate working pressure ensures that the gas can blow the filter bags with enough speed and force, effectively removing the dust attached to the surface of the filter bags.

- Ambient Temperature: It can adapt to an ambient temperature range of -10℃ – 55℃. This enables it to work normally in a variety of industrial environments. Whether in the cold regions of northern China or the hot factories in southern China, the DMF-Z-40 pulse valve can operate reliably without being overly affected by temperature changes.

- Working Medium: It is only suitable for clean air as the working medium. Clean air can ensure the unobstructed gas circuit inside the pulse valve, preventing impurities from wearing or blocking key components such as the diaphragm and valve core, thus extending the service life of the pulse valve and ensuring its stable and reliable operation.

- Diaphragm Life: The diaphragm, as a key vulnerable part of the pulse valve, directly affects the maintenance cycle and use cost of the pulse valve. The diaphragm of the DMF-Z-40 pulse valve is carefully designed and selected. Under normal working conditions, it can withstand more than 1 million blows or be used continuously for 2 – 3 years. This long-life design significantly reduces the workload and frequency of equipment maintenance, improves production continuity and stability.

- Connection Thread: It adopts a ZG1 1/2″ connection thread. This standard thread connection method has good sealing performance and stability, making it convenient to connect with the metal pipe of the air storage tank and the blowpipe of the dust removal box, ensuring no leakage occurs during the flow of high-pressure gas.

- Dimensions and Weight: Its length is 140mm, width is 125mm, height is 170mm, and the overall weight is 1.6kg. The compact and reasonable size design allows it to adapt to various dust removal equipment with different spatial layouts. Its light weight also facilitates the operation of installation and maintenance personnel.

-

DMF-Z-40 Pulse Valve: A Reliable Assistant for Industrial Dust Removal

In many aspects of industrial production, dust treatment has always been a crucial issue. Whether it is to ensure the stable operation of production equipment or to meet the requirements of the working environment and environmental protection, an efficient dust removal system is essential. Among various dust removal equipment, the pulse valve, as one of the core components, directly affects the overall performance of the dust removal system. Today, we will have an in-depth understanding of a widely used pulse valve in the industrial field – the DMF-Z-40 pulse valve.

I. Product OverviewThe DMF-Z-40 pulse valve is a right-angle type valve, with a 90℃ angle between its inlet and outlet. This unique structural design gives it significant advantages in installation and connection. It is especially suitable for the connection between the air storage tank and the dust removal blowpipe, ensuring smooth gas flow and providing the required cleaning gas pulses for the dust removal system. As the “switch” for compressed air in the cleaning blowpipe system of pulse bag dust collectors, it plays a vital role in the entire dust removal process, directly determining the efficiency and effectiveness of filter bag cleaning by the dust collector.II. Working PrincipleThe working principle of the DMF-Z-40 pulse valve is based on electromagnetic control and gas circuit switching. When the pulse valve is not energized, high-pressure gas enters the lower air chamber from the inlet. At this time, the gas slowly enters the decompression chamber through the constant pressure pipeline between the upper and lower shells and the throttle hole in it. Since the valve core tightly blocks the pressure relief hole under the action of the spring, the gas cannot escape, keeping the pressure in the decompression chamber the same as that in the lower air chamber. Under the elastic force of the spring, the diaphragm seals the blowpipe tightly, preventing the gas from rushing out.When the pulse valve receives the electrical signal output by the pulse blowing control instrument, the valve core lifts upward against the spring resistance under the strong action of electromagnetic force, and the pressure relief hole is opened immediately. At this time, the gas quickly escapes from the pressure relief hole. Due to the current-limiting effect of the throttle hole in the constant pressure pipeline, the gas outflow speed from the pressure relief hole is much faster than the inflow speed of the gas from the constant pressure pipe of the decompression chamber, causing the pressure in the decompression chamber to drop rapidly and become lower than that in the lower air chamber. Under the pressure difference between the upper and lower air chambers, the gas in the lower air chamber generates enough thrust to lift the diaphragm, opening the blowpipe, and a powerful gas blowing flow rushes out instantly to clean the filter bags efficiently. When the electrical signal disappears, the electromagnetic force also disappears, and the valve core resets under the action of the spring, blocking the pressure relief hole. The pressure in the decompression chamber gradually recovers, and the diaphragm seals the blowpipe again, completing a full working cycle. -

DMF – Z-2 – 20 Valve: The High – Efficiency Dust Cleaning Tool in the Industrial Field

In numerous aspects of industrial production, dust treatment has always been a crucial issue. A large amount of dust not only affects the production environment and endangers the health of workers but may also cause damage to equipment and reduce production efficiency. To solve this problem, various dust removal equipment has emerged, and among these devices, the DMF – Z-2 - 20 valve plays an extremely vital role.

The DMF - Z-2 - 20 valve, whose full name is the right – angle electromagnetic pulse valve, is the core component of the pulse jet dust collector’s cleaning and blowing system, much like the “heart” of the entire dust removal system. As a key type of pulse jet valve, it mainly functions as a “switch” for compressed air. Under the precise control of the output signal from the pulse jet control instrument, it conducts blowing and dust cleaning on the filter bags row by row (or chamber by chamber). Just like a well – trained conductor, it accurately controls the dust cleaning rhythm, ensuring that the resistance of the dust collector remains within the set reasonable range. This effectively guarantees the high – efficiency processing capacity and excellent dust collection efficiency of the dust collector, highlighting the importance of electromagnetic pulse valves in industrial dust removal.In terms of structural design, the DMF - Z-2 - 20 valve demonstrates unique ingenuity. The included angle between its inlet and outlet is cleverly designed to be 90°, and this right – angle structure is highly suitable for the installation and connection of the air bag and the dust collector’s blowing pipe. It ensures unobstructed air flow, providing a strong and stable air pulse for the dust cleaning process, similar to a wide and smooth highway that enables compressed air to reach the areas requiring dust cleaning quickly and efficiently. This optimized design makes the DMF - Z-2 - 20 valve a standout among pulse jet valves in terms of practicality and performance.Regarding the working principle, the DMF - Z-2 - 20 valve embodies sophisticated mechanical and electromagnetic principles. The diaphragm, acting like a sensitive “goalkeeper,” clearly divides the electromagnetic pulse valve into front and rear air chambers. When compressed air is connected, it slowly enters the rear air chamber through the throttle hole, much like a silent visitor. At this time, the pressure in the rear air chamber gradually increases, similar to an inflating balloon, pressing the diaphragm assembly tightly against the valve’s outlet, keeping the electromagnetic pulse valve in a stable “closed” state. However, when the pulse jet control instrument sends out an electrical signal, a dramatic change occurs. This electrical signal acts like an urgent command, causing the armature of the electromagnetic pulse valve to move backward rapidly, instantly opening the vent hole of the rear air chamber. The air in the rear air chamber loses pressure rapidly, like a burst dam. Under the strong effect of the pressure difference, the diaphragm assembly moves backward quickly, opening up a passage for the compressed air, allowing it to be ejected with a powerful blowing force through the valve outlet. At this moment, the electromagnetic pulse valve enters the “open” state for efficient dust cleaning of the filter bags. When the electrical signal from the pulse jet control instrument disappears, the armature of the electromagnetic pulse valve returns to its original position, the vent hole of the rear air chamber closes, the pressure in the rear air chamber gradually increases again, and the diaphragm assembly adheres to the valve’s outlet once more, bringing the electromagnetic pulse valve back to the “closed” state, awaiting the next dust cleaning command. This complex yet precise working mechanism is a key feature of high – performance electromagnetic pulse valves.In terms of material selection, the DMF - Z-2 - 20 valve also demonstrates a pursuit of high quality. Its valve body is usually made of high – quality aluminum alloy materials, such as ADC12 aluminum alloy. This material offers many advantages, including light weight, high strength, and corrosion resistance. It not only reduces the overall weight of the valve, facilitating installation and maintenance but also maintains excellent performance in complex industrial environments, extending the valve’s service life. The diaphragm, on the other hand, is mostly made of high – performance materials like nitrile butadiene rubber (NBR). These materials have excellent flexibility and wear resistance, ensuring good sealing performance during frequent opening and closing operations and guaranteeing the stable operation of the valve. These material choices contribute to the DMF - Z-2 – 20 valve’s reliability and durability as a top – notch pulse jet valve.In practical applications, the DMF - Z-2 – 20 valve can be widely found in various industries. In the cement production industry, it acts like a loyal guardian, safeguarding the cleanliness of the production environment. During cement production, a large amount of dust is generated. The DMF - Z-2 – 20 valve, through precise dust cleaning control, ensures the efficient operation of the dust collector, keeping the dust concentration in the workshop within a safe range. This not only protects the health of workers but also reduces the wear and tear of dust on equipment and improves production efficiency. In the steel smelting industry, facing harsh environments with high temperatures and heavy dust, the DMF – Z – 20 valve can still operate stably. It effectively removes a large amount of dust generated during the smelting process, ensuring the normal operation of production equipment and providing strong support for the smooth progress of steel production. Additionally, in numerous industries such as mining, chemical engineering, and power generation, the DMF - Z-2 – 20 valve plays an indispensable role, becoming a reliable assistant for ensuring environmental cleanliness and stable equipment operation in industrial production. Its wide application across industries further validates the significance of electromagnetic pulse valves like the DMF - Z-2 – 20 in modern industrial operations.In conclusion, the DMF - Z-2 – 20 valve, with its unique structural design, sophisticated working principle, high – quality material selection, and extensive application areas, showcases excellent performance and strong advantages in the field of industrial dust removal. It not only helps enterprises solve the problem of dust pollution but also makes important contributions to achieving the goals of green, efficient, and sustainable industrial production, making it a well – deserved high – efficiency dust cleaning tool in the industrial field. With the continuous advancement of technology and the increasing demands of industrial production, it is believed that the DMF - Z-2 – 20 valve will continue to innovate and develop, bringing more surprises and value to the industrial field. As a prominent electromagnetic pulse valve, it will surely play an even more important role in the future of industrial dust removal and related applications. -

DMF – ZM – 20 Pulse Valve: Unleashing Superior Performance in Industrial Dust Removal

In the ever – evolving landscape of industrial dust removal technology, the DMF -ZM- 20 pulse valve stands out as a revolutionary electromagnetic pulse valve, redefining the standards of efficiency and reliability. As a cornerstone of pulse – jet dust collection systems, this remarkable valve has become indispensable across a wide spectrum of industries, providing an effective solution to the persistent challenge of dust management.The DMF -ZM- 20, a high – performance right – angle electromagnetic pulse valve, is engineered to deliver precise and powerful pulse – jet cleaning, a critical function for maintaining optimal performance in dust collectors. Its primary role as a compressed air control device is pivotal in ensuring that filter bags are cleaned efficiently, thereby enhancing the overall dust – collecting capacity of the system. With its ability to rapidly open and close, the DMF - ZM – 20 pulse valve releases a short, intense burst of compressed air, dislodging dust from the filter surfaces and preventing clogging. This pulsed cleaning mechanism is not only energy – efficient but also significantly extends the lifespan of the filter bags, reducing maintenance costs and downtime.One of the key features that sets the DMF - ZM – 20 pulse valve apart is its innovative design. The 90 – degree angle between the inlet and outlet ports optimizes air flow dynamics, minimizing pressure loss and maximizing the force of the pulse – jet. This design ensures seamless integration with air bags and blowpipes in dust collector systems, facilitating easy installation and maintenance. The valve’s robust construction, typically crafted from high – grade aluminum alloy, offers excellent resistance to corrosion and wear, making it suitable for harsh industrial environments. The use of premium materials, such as nitrile butadiene rubber (NBR) for the diaphragm, further enhances the valve’s durability and sealing performance, ensuring consistent and reliable operation even under frequent cycling.The working principle of the DMF – ZM- 20 electromagnetic pulse valve is a testament to its engineering excellence. When the valve is in the closed state, compressed air enters the rear chamber through a small orifice, building up pressure that holds the diaphragm against the valve seat. Upon receiving an electrical signal from the pulse – jet control unit, the electromagnetic coil is activated, pulling the armature and opening the exhaust port. This sudden release of pressure in the rear chamber causes the diaphragm to snap open, allowing a powerful blast of compressed air to be discharged through the valve outlet. Once the electrical signal ceases, the armature returns to its original position, closing the exhaust port and allowing the rear chamber to repressurize, resetting the valve for the next pulse – jet cycle. This rapid and precise operation is what makes the DMF - ZM – 20 an ideal choice for high – speed, high – volume dust removal applications.In the cement manufacturing industry, where dust generation is a major concern, the DMF - ZM – 20 pulse valve has proven to be a game – changer. By providing consistent and powerful pulse – jet cleaning, it ensures that baghouse filters remain clean and efficient, reducing emissions and improving air quality in the production area. Similarly, in the steel and metalworking sectors, the valve’s ability to withstand high temperatures and abrasive dust makes it a preferred choice for maintaining the performance of industrial dust collectors. In power plants, the DMF – ZM- 20 pulse valve plays a crucial role in keeping electrostatic precipitators and bag filters clean, ensuring compliance with strict environmental regulations.Moreover, the DMF -ZM – 20 electromagnetic pulse valve is highly adaptable, with customizable options available to meet specific application requirements. Whether it’s adjusting the pulse duration, pressure, or frequency, this valve can be fine – tuned to optimize the dust removal process for different types of dust and operating conditions. This versatility, combined with its reliable performance, has made it a popular choice among engineers and plant managers looking for cost – effective and efficient dust removal solutions.In conclusion, the DMF -ZM- 20 pulse valve represents the pinnacle of electromagnetic pulse valve technology, offering unparalleled performance in industrial dust removal. Its innovative design, robust construction, and precise operation make it a reliable and efficient solution for a wide range of industries. As industries continue to strive for cleaner production environments and higher efficiency, the DMF – ZM- 20 pulse valve is set to play an even more significant role in the future of dust management systems, further solidifying its position as a leader in the field of pulse – jet valve technology. -

Analysis of the Function of Diaphragms in Electromagnetic Pulse Valves

In the complex pneumatic systems of modern industry, although the diaphragms of electromagnetic pulse valves may seem insignificant, they play a crucial role. The quality of their performance directly affects the operational efficiency and stability of the entire system. A thorough exploration of the functions of diaphragms in electromagnetic pulse valves helps us better understand the operating mechanisms of industrial equipment.From the perspective of working principles, the diaphragm of an electromagnetic pulse valve is the core component for achieving precise control. When the electromagnetic coil of the electromagnetic pulse valve is energized, an electromagnetic force is generated, attracting the diaphragm to overcome the spring force and back pressure. The diaphragm deforms instantaneously, opening the valve port, allowing compressed air to rapidly pass through the pulse valve into the blowpipe and jet out at high speed in an extremely short time, performing a powerful cleaning of the filter bags in dust collectors. When the electromagnetic coil is de-energized, the electromagnetic force disappears, and the diaphragm quickly resets under the action of the spring force and back pressure, closing the valve port and cutting off the air flow. In this process, the diaphragm acts like an accurate “commander,” controlling the on-off of the air flow through its own deformation and resetting, achieving precise operation of the pulse injection.In dust collection systems, the role of the diaphragm in electromagnetic pulse valves is particularly critical. Take bag dust collectors as an example. As the dust collection work continues, dust will continuously adhere to the surface of the filter bags, increasing resistance and affecting dust collection efficiency. At this time, the pulse injection system controlled by the diaphragm of the electromagnetic pulse valve comes into play. Through an instantaneous high-pressure injection, it removes the dust on the surface of the filter bags, restoring the air permeability of the filter bags and ensuring the long-term stable operation of the dust collector. The rapid response and reliable sealing performance of the diaphragm ensure that each injection is accurate and efficient, extending the service life of the filter bags and reducing maintenance costs. Statistics show that in dust collection systems using electromagnetic pulse valve diaphragms with good performance, the replacement cycle of filter bags can be extended by 30% – 50%.In addition to the dust collection field, diaphragms of electromagnetic pulse valves are also widely used in other industrial scenarios. In industries with extremely high hygiene requirements, such as food and pharmaceuticals, pneumatic conveying systems often use electromagnetic pulse valves to control the conveying of materials. The good sealing and corrosion resistance of the diaphragm can effectively prevent material leakage and contamination, ensuring product quality and safety. In automated production lines of industries such as automotive manufacturing and mechanical processing, diaphragms of electromagnetic pulse valves are used to control the actions of cylinders, enabling precise grasping, handling, and assembly of components. Their fast switching actions and stable performance improve the degree of automation and production efficiency of the production lines.With its unique function of controlling air flow, the diaphragm of the electromagnetic pulse valve plays an indispensable role in the industrial field. With the continuous development of industrial technology, the performance requirements for diaphragms of electromagnetic pulse valves are also increasing day by day. In the future, they will develop towards a more efficient, reliable, and intelligent direction, continuing to escort industrial production.