Products

-

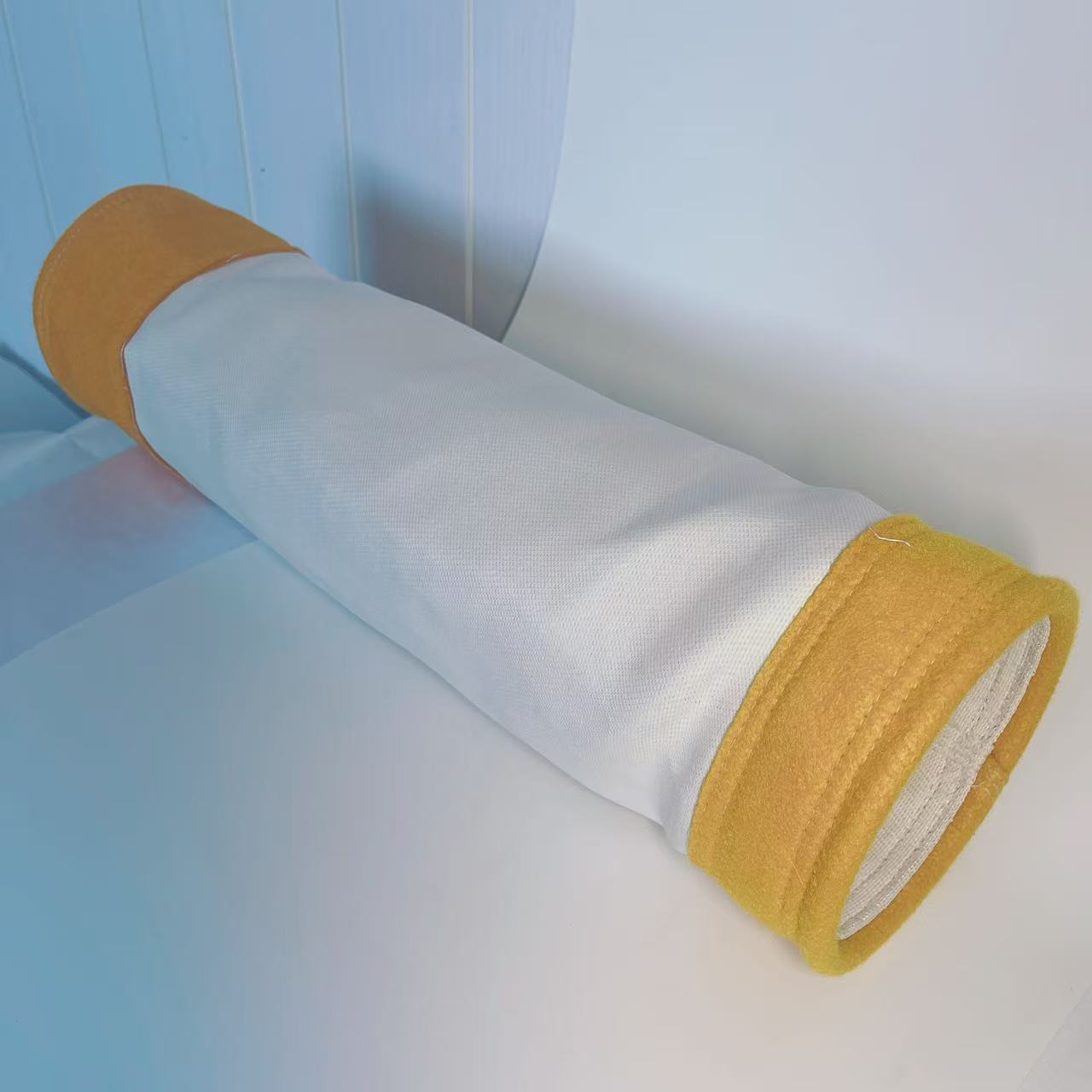

Industrial dust filter bag, all kinds of materials

Unleash Precision Filtration with Our Industrial-Grade Filter Bags!

- Diverse Materials, Unrivaled Performance: Choose from high-quality polyester, nylon, and polypropylene. Each material is engineered to deliver exceptional filtration, whether it’s withstanding harsh chemicals (polypropylene) or providing excellent strength and durability (nylon and polyester).

- Ultra-Precise Filtration: With a wide spectrum of micron ratings available, our filter bags can trap particles of varying sizes. From the tiniest microparticles to larger debris, we’ve got you covered for any filtration need.

- Customizable for Your Convenience: Multiple top options, including ring, drawstring, and flange, ensure a perfect fit for your existing equipment. Tailor the filter bag to your specific setup effortlessly.

- Woven or Felt, Your Call: Our woven and felt materials offer different filtration advantages. Woven bags provide enhanced structural integrity, while felt bags offer higher filtration efficiency. Pick the one that suits your application best.

- Sizes Galore: Available in sizes #1, #2, #3, #4, our filter bags are adaptable to various filtration systems. No matter the scale of your operation, we have the right size for you.

-

Industrial Dust Removal Filter Bag P84 Material with Glass Fiber PTFE Pocket Filter Industrial Dust Filter Bag

Industrial Dust Removal Filter Bag

It is made of P84 material and is equipped with a glass fiber PTFE pocket filter. This is an industrial dust filter bag.Detailed DescriptionOverall Overview

This is an industrial dust removal filter bag that plays a crucial and indispensable role in industrial production scenarios where a large amount of dust is generated, such as cement plants, steel mills, power plants, waste incineration plants, etc. It can effectively capture and filter dust, ensuring that the discharged gas meets environmental protection standards. Meanwhile, it also helps protect production equipment and the working environment.Material Aspects- P84 Material: P84 fiber is a high-performance synthetic fiber with excellent high-temperature resistance. It can generally be used continuously at a high temperature of 260°C, and it can even withstand higher temperatures instantaneously. It also has outstanding chemical stability and can resist the erosion of a variety of chemical substances, showing good tolerance to corrosive gases and liquids such as acids and alkalis. Moreover, P84 fiber has a high filtration efficiency, which can effectively intercept and capture dust particles of various particle sizes, providing a reliable guarantee for industrial dust removal.

- Glass Fiber: Glass fiber features high strength and high modulus, which can enhance the overall mechanical properties of the filter bag, making it more robust and durable, and less prone to damage. At the same time, glass fiber also has a certain degree of high-temperature resistance. When used in combination with P84 material, it further improves the stability and reliability of the filter bag in high-temperature environments.

- PTFE: Polytetrafluoroethylene (PTFE) has an extremely low surface energy, which makes it difficult for dust to adhere to the surface of the filter bag. The dust can be easily removed by the dust cleaning system, thus ensuring the filtration performance and service life of the filter bag. PTFE also has excellent chemical stability and weather resistance, and can maintain stable performance in various harsh industrial environments.

Structural Features- Bag Filter: It adopts a bag structure, which has a large filtration area and can handle a large amount of dusty gas per unit time. The filter bag is usually cylindrical or oval in shape, with one end closed and the other end open. The open end is connected to the pipeline or box of the dust removal equipment. The dusty gas enters the filter bag from the open end. After being filtered by the filter material, the dust is intercepted on the inner surface of the filter bag, and the purified gas is discharged through the pores of the filter bag.

- Pocket Filter (Bag-in-bag Structure): The so-called bag-in-bag structure means that some small bag-shaped structures are set inside the large filter bag. These small bags can further increase the filtration area and improve the filtration efficiency. At the same time, the design of the small bags can also make the distribution of dust more uniform during the filtration process, reduce the accumulation of dust in local areas, and improve the overall performance of the filter bag.

In general, this industrial dust removal filter bag can play an efficient and stable filtering role in the field of industrial dust removal, providing strong support for the environmental protection and sustainable development of industrial production. -

Working Principles of Dust Collection Equipment Filter Bags

Dust collection equipment filter bags operate through the combined action of multiple principles to achieve efficient purification of dusty gases:1. Sieving Effect

The filter bag functions like a sieve with a specific pore size. When dusty gas passes through, dust particles larger than the pore size of the filter bag cannot penetrate and are directly intercepted on the surface of the filter bag. For example, in some wood – processing workshops, large wood chips are intercepted by sieving.2. Inertial Impaction

When the dusty gas stream passes through the filter bag, the direction of the gas flow changes. Larger – mass dust particles, due to inertia, cannot change direction in time along with the gas flow and will collide with the fibers of the filter bag and be captured. In steel mills, during the high – temperature smelting process, large – sized dust particles are intercepted by inertial impaction when the gas passes through the filter bag.3. Interception Effect

Some dust particles slightly smaller than the pore size of the filter bag, when brought close to the filter bag fibers by the gas flow, will be directly intercepted by the fibers. It’s similar to how small objects in a narrow passage are easily blocked by obstacles beside them.4. Diffusion Effect

For extremely fine dust particles, they will perform irregular Brownian motion under the influence of the thermal motion of gas molecules, which increases the chance of contacting and being adsorbed by the filter bag fibers. In chemical production, some fine dust is captured by the filter bag through the diffusion effect.5. Electrostatic Adsorption

Some filter bag materials generate static electricity during friction with dust, or they already carry static electricity. Dust particles will be adsorbed onto the filter bag due to electrostatic attraction, enhancing the filtration effect. For example, some filter bags specially used to handle flammable dust often utilize the principle of electrostatic adsorption to improve dust removal efficiency.These principles work in concert, enabling the filter bags of dust collection equipment to effectively purify dusty gases, ensuring a clean production environment and the normal operation of equipment. -

High Quality ASCOAASF A-Z-40S 24V IP65 Electromagnetic Pulse Valve Right Angle air Solenoide Diaphragm Valve

1. Superior Build Quality

The ASCO AASF A – Z – 40S electromagnetic pulse valve is crafted with precision and durability in mind. Its body is constructed from high – grade materials, ensuring resistance to corrosion and wear, even in harsh industrial environments. This robust build not only guarantees a long service life but also contributes to the valve’s reliable performance over time.2. Voltage and Power

Operating on a 24V power supply, this valve is designed to be energy – efficient while providing consistent and powerful actuation. The 24V voltage is widely used in industrial control systems, making it easy to integrate into existing setups. It can quickly respond to electrical signals, allowing for precise control of air flow within the system.3. IP65 Protection Rating

Featuring an IP65 protection rating, the valve offers excellent protection against dust and water ingress. The “IP65″ means that it is dust – tight (6 – highest level of dust protection) and protected against water jets (5 – can withstand water projected from a nozzle in any direction). This makes it suitable for use in various industrial applications, including those in dusty environments like cement plants, or areas where it may be exposed to splashing water, such as car wash facilities or outdoor industrial equipment.4. Right – Angle Design

The right – angle configuration of the ASCO AASF A – Z – 40S is strategically designed to optimize air flow and installation flexibility. This design allows for easy connection to pipelines at a 90 – degree angle, which can be beneficial in space – constrained areas or when a change in the direction of air flow is required. It also helps in reducing pressure drops and ensuring efficient air distribution within the system.5. Diaphragm Valve Mechanism

As a diaphragm valve, it utilizes a flexible diaphragm to control the flow of air. When an electrical current is applied to the solenoid, the magnetic field generated lifts the diaphragm, opening the valve and allowing air to pass through. Once the current is cut off, the diaphragm returns to its original position, closing the valve and stopping the air flow. This diaphragm – based mechanism provides a reliable and efficient way to control air pulses, making it ideal for applications such as dust collection systems, where precise and rapid air pulses are needed to clean filter bags.In summary, the ASCO AASF A – Z – 40S 24V IP65 electromagnetic pulse valve is a high – quality, versatile, and reliable component that can meet the demanding requirements of a wide range of industrial applications. -

Hydraulic PU seals, industrial seals first choice, hot sales!

Hydraulic PU Seals: The Prime Choice for Industrial Sealing, Now Seeking Partners!

In the industrial sector, the stable operation of hydraulic systems is of utmost importance. Hydraulic PU seals, as the core components, are witnessing a surging market demand.These seals are suitable for various construction machinery such as excavators, loaders, as well as hydraulic pumps, hydraulic cylinders and other equipment. They can function perfectly in both harsh mining environments and high – precision industrial scenarios.With outstanding performance, the polyurethane material endows excellent wear resistance. It can withstand high – frequency friction, significantly extending the service life and reducing downtime for maintenance. Under complex working conditions, it has good chemical stability against hydraulic oil and can resist external corrosion, ensuring reliable sealing.By promoting on the platform, we can precisely reach industrial customers. We sincerely invite merchants to cooperate. Leverage the platform’s traffic to enhance product visibility and explore a vast market. Let’s work hand in hand for a win – win situation and ensure the efficient operation of the industrial sector. -

304 stainless steel filter cage, precision manufacturing, suitable for dust filter bag

Are you looking for high – quality and durable industrial dust – collection accessories? This 304SS filter cage is definitely the best choice. Made of high – quality 304 stainless steel, each frame has undergone strict quality control and has super strength and anti – deformation ability.

In a high – intensity working environment, it can still provide reliable support for the filter bags, preventing the filter bags from collapsing and being damaged, and extending the service life of the filter bags. Moreover, its surface is smooth, making it difficult for dust to adhere and accumulate, and it is easy to clean and maintain. Invest in our 304SS filter cages to inject strong impetus into your industrial dust – collection system, reduce operating costs, and create more value.

-

Filter cages for industrial equipment

We deeply understand that different industrial scenarios have different requirements for dust – collection equipment. Therefore, we launch a professional customization service for galvanized filter cages. No matter the size of your dust – collection system or what unique requirements you have for filtration accuracy and dimensional specifications, we can rely on advanced technology and rich experience to create exclusive filter cages for you.

Every link from design to production strictly adheres to high standards, ensuring that the customized galvanized filter cages seamlessly cooperate with your dust filter bags, precisely filtering every dust particle, escorting your production environment, and helping enterprises achieve the goals of green and efficient production.

-

304SS Filter Cages for Industrial Dust Collection

In the field of industrial dust collection, precise fit is of vital importance. Our 304SS filter cages are crafted through precision processes to perfectly match various dust filter bags. The 304 stainless – steel material endows them with excellent corrosion resistance. Whether in a humid and dusty environment or under mild acid – alkali erosion conditions, they can operate stably and are not easily damaged for long – term use.

Their scientific and reasonable structural design effectively supports the filter bags, ensuring full utilization of the filtration area and greatly enhancing dust – collection efficiency. It helps enterprises upgrade the cleanliness of their production environments and easily meet environmental protection challenges. Choosing our 304SS filter cages means choosing an efficient and durable industrial dust – collection solution.

-

What is the specific working principle of pulse valve coil?

The working principle of the 24V pulse valve coil mainly involves the interaction between electricity and magnetism. Here is a detailed explanation:

- Electromagnetic induction: The pulse valve coil is essentially a solenoid, which is made of many turns of copper wire wound around a core. When a 24V alternating current is applied to the coil, according to Faraday’s law of electromagnetic induction, an alternating magnetic field is generated around the coil. The strength and direction of this magnetic field change with the frequency of the alternating current.

- Magnetic force generation: The core inside the coil is usually made of a ferromagnetic material such as iron. When the coil is energized, the core is magnetized by the magnetic field, which significantly enhances the magnetic field intensity. This strong magnetic field exerts a magnetic force on the movable parts of the pulse valve, such as the armature.

- Valve actuation: The magnetic force causes the armature to move. When the current is turned on, the magnetic force attracts the armature, which in turn opens the valve to allow the fluid (gas or liquid) to pass through. When the current is cut off, the magnetic field disappears, and the armature returns to its original position under the action of a spring or other restoring force, closing the valve and stopping the fluid flow. By controlling the on – off time of the current, the opening and closing time of the pulse valve can be accurately controlled, thereby achieving precise control of the fluid flow rate and pressure in the filtering and purifying device.

-

The customized 220V pulse valve coil is used for the filtering and purifying device parts

The customized 220V pulse valve coil is a crucial component within the filtering and purifying device. When an electrical current is applied to this coil, it generates a powerful magnetic field. This magnetic field, in turn, acts as the driving force behind the operation of the pulse valve.

During the normal operation of the filtering and purifying device, the pulse valve coil plays a key role in controlling the flow of gas or liquid. It enables the rapid opening and closing of the pulse valve. For instance, in a dust – collecting filtering system, when the filter elements become clogged with contaminants, the pulse valve coil receives an electrical signal. This signal activates the coil, causing the pulse valve to open suddenly. High – pressure air or cleaning fluid then rushes through the opened valve, forcefully blasting away the accumulated dust and debris from the filter elements. This timely and efficient cleaning action ensures that the filter elements can maintain their high – performance filtering capabilities, effectively purifying the air or liquid passing through the device. In essence, the customized 220V pulse valve coil is the core element that guarantees the smooth operation and continuous purification efficiency of the filtering and purifying device parts.

-

Solenoid Air Valve Controller DMK-4CSA-6 220VAC Input 24VDC Output

Solenoid Air Valve Controller DMK-4CSA-6 220VAC Input 24VDC Output

Functions of Pulse Controllers- Precise Timing and Sequencing

Pulse controllers are engineered to exercise exacting control over the timing and sequencing of pulses. They possess the capacity to generate pulses at meticulously defined intervals, a feature of paramount importance across numerous industrial and technological processes. In the context of a dust collector system, for example, the controller precisely times the emission of high – pressure air pulses. This ensures that filter bags are cleaned at the most opportune moments. By doing so, it effectively prevents excessive dust accumulation, all while minimizing compressed air wastage, thus enhancing the overall efficiency and sustainability of the system. - Adjustable Pulse Parameterization

These controllers offer the flexibility to fine – tune a diverse range of pulse parameters, including pulse width, amplitude, and frequency. This ability to precisely customize these parameters renders them highly versatile and adaptable to a wide array of applications. In manufacturing processes involving the activation of solenoid valves, the pulse width can be adjusted with great precision. This adjustment directly controls the duration of valve opening, enabling the accurate regulation of fluid or gas flow rates. Such precision is crucial for maintaining the quality and consistency of production processes. - System Integration and Coordination

Pulse controllers play an indispensable role in integrating and coordinating disparate components within a complex system. They are designed to interface seamlessly with sensors, actuators, and other control devices. In an automated assembly line, the pulse controller receives real – time signals from sensors that detect the position of components. Based on these incoming signals, it promptly sends out precisely calibrated pulses to actuators, such as motors or pneumatic cylinders. This coordinated action enables the execution of tasks like part picking, placing, and fastening in a highly synchronized and efficient manner, thereby optimizing the productivity and reliability of the assembly line.

- Precise Timing and Sequencing

-

Right angle Electromagnetic Pulse Gas Valve Solenoid Valve

Here is the relevant information about industrial filter valves:

Overview

Industrial filter valves are an indispensable device in the pipeline series for conveying media. They are usually installed at the inlet end of equipment such as hydraulic control valves, pressure reducing valves, pressure relief valves, and fixed water level valves. They are used to remove impurities in the media and prevent particulate impurities from entering the passage and causing blockages, so as to protect the fittings on the equipment pipeline from wear and blockages.Working Principle

- Impurity Interception: When the fluid passes through the filter valve, the filter elements such as the filter screen or filter cartridge will intercept the impurity particles larger than the pore size of the filter elements, allowing the clean fluid to pass through the filter elements, thus realizing the separation of impurities from the fluid. For example, in a Y-type filter, when the fluid enters the filter basket through the main pipe, the solid impurity particles are blocked in the filter basket, and the clean fluid is discharged from the filter outlet through the filter basket.

- Backwashing Function: Some industrial filter valves are equipped with an automatic backwashing function. When the impurities in the filter accumulate on the surface of the filter cartridge and cause the pressure difference between the inlet and outlet to increase to the set value, or when the set backwashing time is reached, the backwashing mechanism will be driven to work. For example, in an automatic sewage discharge filter, the backwashing suction cup opening will be aligned with the inlet of the filter cartridge, the sewage discharge valve will be opened, the system will relieve pressure and drain water, and a part of the clean circulating water will flow from the outside to the inside of the filter cartridge by using negative pressure, flushing the impurity particles adsorbed on the inner wall of the filter cartridge into the suction cup along with the water flow and discharging them from the sewage discharge valve.