Products

-

Wide Applications of Filter Bags

In the industrial field, filter bags can be seen everywhere. In the chemical industry, they are used for the filtration of various chemical raw materials and products, ensuring product quality and the smooth progress of the production process. In the food and beverage industry, from the filtration of raw materials to the filtration before filling of finished products, they ensure the safety and taste of food and beverages. In the pharmaceutical industry, which has extremely high requirements for filtration accuracy and hygiene, filter bags are used for the filtration of liquid medicines, removing impurities and microorganisms to ensure the quality and safety of drugs.

In the environmental protection field, filter bags play an important role. In sewage treatment plants, filter bags are used to filter impurities and suspended solids in sewage, laying the foundation for subsequent treatment processes. In industrial waste gas treatment, dust – removal filter bags can effectively reduce dust emissions, reduce pollution to the atmospheric environment, and help achieve environmental protection goals.In daily life, filter bags also quietly serve us. The water purifiers at home may use filter bags to filter impurities in water, allowing us to drink cleaner water. The pour – over coffee filter bags used by coffee lovers can filter out coffee grounds, bringing a pure coffee taste. Even in the kitchen, some filter bags for making soup can filter out the residue in the soup, making the soup more delicious.Although filter bags seem inconspicuous, they play an indispensable role in various fields. With the continuous progress of science and technology and the increasing requirements for filtration, the performance and quality of filter bags are also constantly improving. In the future, they will continue to serve as key guardians in the filtration world, escorting our lives and production. -

The Ingenious Working Principle of Filter Bags

he working principle of filter bags is mainly based on functions such as screening, interception, and adsorption. Taking liquid filter bags as an example, when the liquid flows from the inside to the outside of the filter bag, particles larger than the pore size of the filter bag will be directly intercepted inside the bag, which is the screening function. For some smaller particles, although they can pass through the pore size of the filter bag, they will be retained inside the filter bag due to the interception of the filter bag fibers and the mutual collision of particles, which belongs to the interception function. In addition, the material of the filter bag itself may have certain adsorption properties for some substances, which can adsorb some tiny impurities and pollutants, further improving the filtration effect.

In the entire filtration system, filter bags work together with filter containers, support baskets, etc. The liquid or gas to be filtered is injected from the top of the filter bag supported by the support basket, making the fluid evenly distributed on the entire surface of the filter bag, avoiding adverse factors such as turbulence. This design can make full use of the filtration area of the filter bag and improve the filtration efficiency. Moreover, the filtered particles are intercepted inside the bag, and the filtered fluid will not be contaminated when replacing the filter bag. Some filter bags are also designed with handles for quick and convenient replacement of filter bags. -

Filter Bags: The Key Guardians in the Filtration World

In the world we live in, filtration is everywhere, from the water and coffee we drink daily to various liquids and gases in industrial production. Among numerous filtration devices, filter bags have become a crucial part of the filtration process due to their unique performance and wide applications.I. A Wide Variety of Filter Bags

Filter bags are made of diverse materials, enabling them to meet various filtration requirements. Common materials include polyester, polypropylene, nylon, glass fiber, FMS (Fluoride Modified Synthetic Fiber), etc.Polyester filter bags have good chemical stability and certain strength and are widely used in general liquid filtration, such as in industrial wastewater treatment and chemical liquid filtration. Polypropylene filter bags have good resistance to acids and alkalis and are often used in some liquid filtration scenarios with strong corrosiveness, such as the filtration of electroplating solutions and chemica raw material liquids. Nylon filter bags have precise pore sizes and can achieve high – precision filtration. They play an important role in the food and beverage industry, such as in the filtration of wine and fruit juice, ensuring the purity of products. Glass fiber filter bags have excellent high – temperature resistance and can be used for the filtration of high – temperature gases, for example, in the high – temperature flue gas dust removal in steel plants and cement plants. FMS filter bags are not only resistant to high temperatures but also highly corrosion – resistant, suitable for some harsh industrial environments.Iln terms of structure and use, filter bags can be divided into liquid filter bags, dust – removal filter bags, air – purification filter bags, etc. Liquid filter bags have different filtration accuracies ranging from 0.5 microns to 300 microns, which can meet various needs from high – precision liquid filtration in the electronics industry to general industrial liquid rough filtration. Dust – removal filter bags are mainly applied in the industrial dust – removal field. In places like cement plants and steel plants, they can effectively capture dust, reduce dust pollution to the environment, and ensure a clean production environment. Air – purification filter bags are commonly found in air – conditioning systems and air purifiers, filtering dust, pollen, bacteria, and other pollutants in the air to provide people with fresh and healthy air. -

Product Advantages of Water Filter Bags: Superior Performance Making It the Industry’s First Choice

Water filter bags hold a pivotal position in the water treatment market and are highly favored by various industries. This is mainly due to a series of remarkable and unique product advantages they possess.High – efficiency Filtration Performance for Precise Water Purification

One of the core advantages of water filter bags is their outstanding filtration performance. According to different filtration requirements, it can accurately match filter cloths of various pore sizes, efficiently intercepting impurities ranging from large particles in millimeters to fine impurities in microns or even nanometers. For example, in industrial wastewater treatment, the wastewater from some metal processing industries often contains a large number of large – sized metal debris, sediment and other impurities, as well as micron – sized colloidal particles and bacteria and microorganisms generated by chemical reactions. By carefully selecting the appropriate pore – sized filter cloth, water filter bags can separate these impurities of different particle sizes one by one, making the treated. -

The wide application scenario of water filter bag: protect the water safety of various industries

With its excellent filtration performance, water filter bags have a wide range of applications in many fields, providing a strong guarantee for the water safety and production process in various industries.

In the field of drinking water treatment, water filtration bags are an important line of defense to ensure healthy drinking water for residents. When the water works purify the raw water, filter bags with different precision will be used to remove impurities such as sediment, algae, bacteria and some viruses in the water. After layers of filtration, the raw water meets the drinking water sanitation standards stipulated by the state before it is transported to thousands of households. For example, in some areas where the water source is polluted, by installing high-precision water filter bag equipment, harmful pollutants can be effectively removed from the water, so that residents can drink soothing water.

In industrial production, water filter bags play an irreplaceable role. In the electronics industry, the production process has very high requirements for water quality, and even extremely small impurities can affect the quality of electronic products. The water filter bag can accurately filter out the particles and microorganisms in the water, providing ultra-pure water for chip manufacturing, circuit board cleaning and other processes to ensure the stable performance of electronic products. In the chemical industry, a variety of chemical reactions require pure water as a raw material or reaction medium. The water filter bag can remove impurities and harmful ions in the water, prevent these substances from interfering with the chemical reaction, and ensure the quality of chemical products and the smooth progress of the production process.

In the field of environmental protection, water filter bags perform well in sewage treatment and rainwater collection and utilization. Sewage treatment plants use filter bags to pretreat sewage, remove large particles of impurities, and reduce the burden of subsequent treatment process. In the rainwater collection system, the filter bag can filter out the impurities such as leaves and dust in the rainwater, so that the collected rainwater can be used for non-drinking purposes such as irrigation and car washing, and realize the effective use of water resources.

In addition, in aquaculture, landscape fountains and other fields, water filtration bags also play an important role in maintaining the cleanliness and ecological balance of water bodies. It can be said that the application scenarios of water filter bags are extremely wide, and it is like a silent guardian to protect the quality of water in various industries. -

The working principle of water filter bag: the core mystery of efficient purification

In today’s era of pursuit of high-quality water resources, water filter bags, as a key filtration equipment, play a vital role. So, how is the water filter bag to achieve efficient filtration, so that the water quality is purified? There are many subtleties in how it works.

The water filter bag mainly removes impurities in the water by means of physical interception. It is usually made of a filter cloth of a specific material, which has different pore size specifications, from the micron level to the finer level. When the water containing impurities passes through the filter bag, particles, suspended solids, colloids and other impurities larger than the filter cloth aperture will be blocked by the filter cloth and cannot pass through, thus being trapped in the filter bag.

For example, in the treatment of industrial wastewater, the wastewater may contain a large number of metal particles, sediment, and suspended substances formed by various chemical substances. The water filter bag can accurately intercept these impurities, so that the filtered water meets the discharge standard or can be further treated and reused. In the swimming pool water treatment, the filter bag can effectively remove impurities such as hair, dander and dust brought by the human body, ensure that the pool water is clear and clean, and provide people with a safe and comfortable swimming environment.

In addition, the filtration effect of the water filter bag is also related to its structural design. Some filter bags adopt multi-layer structure, and the filter cloth aperture of different layers becomes smaller gradually, forming a gradient filtration mode. In this way, the water flow through the multi-layer filter cloth process, impurities will be gradually intercepted, greatly improving the accuracy and efficiency of filtration. Moreover, the material selection of the filter bag is also extremely critical, high-quality filter cloth material not only has good filtration performance, but also needs to have a certain strength and corrosion resistance to ensure stable operation in different water quality and working environment.

It is based on these physical interception, structural design and material characteristics and other factors, water filter bags can efficiently achieve water purification, becoming an indispensable water treatment equipment in many fields.

-

Display Control Instruments: A Key Link in Industrial Process Automation

Display control instruments, as important components of detection and control products in industrial process automation systems, have left a profound mark and played an irreplaceable role in many industries, including national defense, steel, power, petrochemicals, machinery, pharmaceuticals, textiles, metallurgy, and printing and dyeing. They are like the intelligent eyes and dexterous hands in industrial production, capable of sensitively perceiving changes in various physical quantities and quickly and accurately regulating relevant equipment.

The core functions of display control instruments include comprehensive processing of various signals such as temperature, pressure, liquid level, and speed on – site. First, they accurately collect these signals to ensure the acquisition of the most real and accurate data. Then, they display the data in a clear and intuitive manner. Whether it is through pointer, recording pen, printing, or display screen, operators can clearly understand the current operating status of the system at a glance. In terms of control, they precisely control relevant equipment based on preset parameters and algorithms, ensuring that the entire production process runs stably in accordance with established technological requirements. They also have a remote transmission function, which can transmit the collected data to a remote monitoring center, facilitating managers to grasp the production situation anytime and anywhere. The communication function enables display control instruments to conduct efficient data interaction with other devices, constructing a large – scale and intelligent industrial automation network. The printing function provides convenience for data preservation and analysis, facilitating subsequent traceability and optimization of the production process.To meet the diverse needs of different industries and scenarios, display control instruments exhibit many remarkable features in technology and design. In terms of anti – interference ability and reliability, they adopt IC chips with higher integration, advanced SMT surface – mount technology, and unique circuit shielding technology. The comprehensive application of these technologies makes display control instruments seem to wear a solid “protective armor,” enabling them to work stably for a long time in an electromagnetic – interference environment and ensuring the accuracy of data and the reliability of control. Their universal input jumper settings are highly innovative. Each instrument can easily achieve input of various indexing numbers, standard signals, remote – transmission pressure signals, and millivolt signals through simple and quick parameter settings, greatly improving the instrument’s versatility and enabling it to adapt to complex and changeable industrial environments. The modular universal circuit structure is also a major highlight. Through simple module combinations, various functions of the instrument can be transformed, from basic measurement and display functions to complex control and communication functions, which can be flexibly adjusted according to actual needs, significantly enhancing the instrument’s versatility and flexibility.In terms of calibration, display control instruments adopt a microcomputer – controlled full – automatic digital calibration system, abandoning the traditional potentiometer adjustment method. This advanced calibration system not only improves the accuracy and efficiency of calibration but also reduces errors and instability factors caused by manual adjustment. Their appearance design also fully considers aesthetics and practicality, with a variety of appearance structures and sizes available, enabling perfect integration with different industrial devices and operating environments. Both the entire machine and the movement assembly adopt a snap – in structure. This ingenious design makes maintenance and disassembly extremely convenient, greatly reducing equipment maintenance costs and downtime. In terms of power supply selection, display control instruments are also very flexible. They can choose conventional AC 220V, 50/60HZ power supply, 90 – 265V switching power supply, or DC 24V power supply to meet the power supply requirements of different occasions. In addition, they can be equipped with RS – 232/RS – 485 or RS – 422 communication interfaces, facilitating connection with the host computer to form a more powerful control system and achieving a higher level of automated control and management. -

A Comprehensive Analysis of Control Instruments

In modern industrial production and numerous technological application scenarios, control instruments play an extremely crucial role. They are like precise commanders, regulating various complex systems in an orderly manner. Essentially, a control instrument is a device that automatically controls the controlled variables. It accurately compares the measured signals with the set values, calculates based on specific control laws for the deviation signals, and finally outputs the calculation results as specified signals to achieve precise control over the entire process.

Control instruments come in a wide variety of classifications. In terms of energy sources, there are electric, pneumatic, and hydraulic control instruments. Electric control instruments are widely used in the industrial field due to their high efficiency, precision, and ease of integration with modern electrical systems. Pneumatic control instruments, on the other hand, hold a certain market share because of their safety in environments with high explosion – proof requirements and their adaptability to certain special processes. Hydraulic control instruments play an important role in situations where high torque and high – power output are required. Structurally, they can be divided into base – mounted and unit – combined types. All components of base – mounted control instruments are closely connected through an inseparable mechanical structure and are installed in a single enclosure. Just one instrument can handle a series of tasks such as measurement, recording, and control in simple automation systems. Common examples include temperature controllers and pressure controllers. They are compact in structure and concentrated in function, suitable for relatively independent small – scale systems with less complex control requirements. Unit – combined controllers, however, consist of multiple units such as 变送 (transmitter), regulation, operation, display, and execution. Standard signals are used for communication between these units. This modular design allows for flexible combination of various units according to different needs, enabling the construction of control systems of different complexities. As a result, it greatly improves the versatility and flexibility of control instruments, and is widely applied in large – scale industrial automation production lines and complex industrial process control systems.There are various sophisticated control laws embedded within control instruments, which are the core of achieving precise control. In the field of chemical automation, common basic control laws include proportional action (P), integral action (I), and derivative action (D). In proportional action, the change in the controller’s output is in strict proportion to the change in the deviation. The larger the deviation, the stronger the control action.In situations such as liquid – level control where strict elimination of residual deviation is not required, proportional action alone can achieve good control results. In integral action, the rate of change of the controller’s output is proportional to the deviation. The longer the deviation exists, the stronger the control action. It is mainly used in situations where high requirements for eliminating residual deviation are imposed. However, it is rarely used alone in the chemical industry. In derivative action, the controller’s output is proportional to the rate of change of the deviation. It can excel in situations where accelerating the regulation process is necessary, and is also seldom used alone in the chemical industry. In practical applications, control laws are often a clever combination of proportional action and other actions. For example, for the control of general parameters such as flow rate, proportional – integral action (PI) is commonly used. It combines the advantages of proportional action’s rapid response to deviation and integral action’s elimination of residual deviation. For objects with large inertia, such as temperature and composition control, proportional – integral – derivative action (PID) is usually adopted. This combination can more comprehensively deal with complex control situations and achieve more accurate and efficient control.Control instruments are widely applied in industrial production and many other industries. They can cooperate seamlessly with various sensors and transmitters to achieve accurate measurement and clear display of physical quantities such as temperature, pressure, liquid level, volume, and force. Moreover, they can coordinate with various actuators to perform PID regulation and control on electric heating equipment, electromagnetic, and electric valves. They also have alarm control and data acquisition functions. In the petrochemical industry, the precise control of key parameters such as reaction temperature and pressure by control instruments is directly related to product quality and the safety and stability of the production process. In the pharmaceutical industry, they ensure the accuracy of raw material ratios during drug production and the precision of finished product packaging dosages, safeguarding drug quality and patient safety. In the food processing industry, they are used for accurate metering of ingredients and finished products, ensuring strict compliance with food quality and safety standards. From large – scale industrial production to fine – scale pharmaceutical and food processing, control instruments are everywhere, providing solid support for the efficient and stable operation of various industries. -

Dust removal equipment controller industry development trend and prospect

In the context of the increasing global environmental awareness and the continuous expansion of industrial production scale, the market demand for dust removal equipment is growing. As the core control component of dust removal equipment, the dust removal equipment controller industry has also ushered in new development opportunities and challenges. In-depth analysis of the development trend of this industry is of great significance for relevant enterprises to grasp the market dynamics and formulate reasonable development strategies.

Technological innovation promotes product upgrading

Deep integration of intelligent control technologyWith the rapid development of cutting-edge technologies such as the Internet of Things, big data and artificial intelligence, intelligence has become an important development trend in the dust removal equipment controller industry. In the future, the dust removal equipment controller will be more intelligent, able to collect and analyze a large number of data related to the operation of the dust removal system in real time, such as dust concentration, equipment pressure, temperature, valve switching status, etc. Through the deep mining and analysis of these data, the controller can use artificial intelligence algorithms to automatically optimize the cleaning strategy and achieve accurate control of the dust removal equipment. For example, according to the generation law and change trend of dust under different working conditions, the pulse width, pulse interval and cleaning cycle are intelligently adjusted, so that the dust removal equipment is always maintained in the best operating state, which not only improves the dust removal efficiency, but also effectively reduces energy consumption and equipment wear. At the same time, the intelligent controller can also achieve remote monitoring and fault diagnosis functions, operators can check the operating status of the equipment anytime and anywhere through mobile phones, computers and other terminal equipment, when the equipment is abnormal, the controller can quickly issue an alarm, and through data analysis to locate the cause of the fault, to provide accurate maintenance suggestions for maintenance personnel. Greatly improve the timeliness and convenience of equipment maintenance.

Application of high precision sensor technology

The application of high precision sensor will further improve the performance of dust removal equipment controller. In the dust removal system, the accurate measurement of dust concentration, pressure, temperature and other parameters is very important for the controller to achieve accurate control. The new high-precision dust concentration sensor can more accurately detect the content of fine dust particles in the air, provide more accurate dust concentration data for the controller, so that it can adjust the cleaning force and frequency according to the actual dust pollution situation. At the same time, the high-precision pressure sensor and temperature sensor can monitor the pressure and temperature changes inside the dust removal equipment in real time, and help the controller to timely find abnormal conditions during the operation of the equipment, such as pressure rise caused by the blockage of the filter bag, equipment overheating and other problems, and take appropriate measures to adjust and warn, to ensure the safe and stable operation of the dust removal equipment.

-

Timer controller:Cleaning Control Function

Main Functions

Cleaning Control FunctionCleaning control is one of the core functions of the dust removal equipment controller. By accurately setting parameters such as pulse width, pulse interval, and cycle interval, the controller can achieve efficient cleaning of filter bags. For example, the pulse width determines the duration of each blow of the electromagnetic pulse valve. An appropriate pulse width ensures that the compressed air effectively removes dust from the surface of the filter bags without causing excessive impact on the filter bags. The pulse interval controls the time interval between adjacent blows. A reasonable pulse interval allows the filter bags to restore their filtering performance sufficiently between two blows, thus ensuring the stable operation of the dust collector.Adjustable Output Channel FunctionDust removal equipment of different scales has different requirements for the number of output channels of the controller. The dust removal equipment controller has the function of adjustable output channels. Operators can use the “+” and “-” buttons of the universal dial switch to set the number of output channels of the controller according to actual needs. This function enables the controller to adapt to various dust removal equipment of different specifications, greatly improving its versatility and flexibility. For instance, a small dust collector may only require a small number of output channels to control a small number of electromagnetic pulse valves, while a large dust removal system may need a large number of output channels to achieve precise control of a large number of pulse valves. -

Dust Removal Equipment Controller: Principles, Functions and Technical Indicators

In modern industrial production, the widespread application of dust removal equipment is crucial for reducing environmental pollution, ensuring the safety of the production environment, and improving production efficiency. As the core component of the dust removal system, the performance of the dust removal equipment controller directly affects the operation of dust removal equipment. This article will delve into the working principles, main functions, and key technical indicators of the dust removal equipment controller.

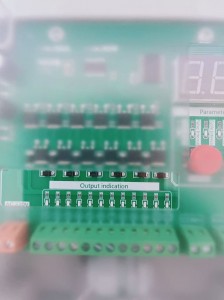

Working PrinciplesThe dust removal equipment controller uses an industrial-grade chip as its control core and coordinates the operation of various components through precise logical operations. Its working process mainly revolves around the control of electromagnetic pulse valves. There are clear setting marks on the printed circuit board, facilitating operators to set the parameters of the controller according to actual needs. After the controller is started, electrical signals are output from each output terminal, which are used to control the opening of electromagnetic pulse valves. Once the electromagnetic pulse valves open, compressed air is blown to clean the filter bags. Meanwhile, the controller is equipped with manual operation buttons. During equipment debugging and the initial operation stage, operators can use these buttons for convenient operation to ensure the normal operation of the equipment.Take the pulse bag dust collector as an example. While filtering dust-laden gas, the dust collector conducts blow cleaning simultaneously. The dust removal controller outputs electrical signals in sequence to control the pulse valves to blow and clean one by one according to the preset pulse width and pulse interval. During this process, the controller monitors the working status of each output point in real time and displays it through the working indication device, enabling operators to quickly judge the equipment operation status. -

Smart Sensors Empower Electromagnetic Pulse Valves, Driving Digital Upgrades in Dust Removal Systems

Advancing industrial intelligence is transforming traditional dust removal equipment through technological innovation. Take the ASCO 353 series pulse valve as an example – its integration with digital sensors provides real-time monitoring and intelligent control solutions for dust systems.Intelligent Monitoring Architecture

This system combines dust concentration meters, differential pressure transmitters, and air tank pressure sensors to collect critical data like filter bag resistance, jetting pressure, and air flow. For instance, differential pressure sensors trigger automatic jetting when resistance thresholds are exceeded, while air tank sensors ensure stable jetting pressure to prevent cleaning failures.Digital Management Advantages- Predictive Maintenance: Analyzing diaphragm cycle frequency and response times predicts component wear and blockages, minimizing downtime.

- Energy Optimization: Dynamic parameter adjustments based on real-time pressure reduce compressed air waste while maintaining cleaning effectiveness.

- Remote Control: Cloud-based platforms enable remote status monitoring and cycle adjustments for cross-regional management.

Case Study

A steel plant deploying smart pulse valves in its sintering machine dust system achieved:- 30% reduction in collector resistance fluctuations

- 25% decrease in jetting frequency

- Annual energy cost savings of ¥180,000

Stable dust emissions below 10mg/m³ were also maintained, supported by automated operational reports for process optimization.

Looking ahead, IoT integration will drive pulse valves toward “adaptive cleaning” through AI algorithms dynamically matching changing operating conditions, propelling industrial dust removal toward higher efficiency, lower carbon footprint, and unmanned operation.