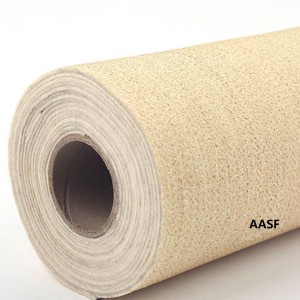

PP filter cloth

PP(Polypropylene) needle punched felt is one of the most common materials for filter cloth. Polypropylene filter needle felt is a specific type of needle felt commonly used in industrial filtration applications. It is a non-woven fabric made by mechanically needling polypropylene fibers, which has good filtration performance and durability. This type of needle felt is mainly used for the filtration and separation of solid particles, liquids or gases. Its production process is similar to the general needle felting production, but the material of choice is polypropylene fiber.

- Capacity: Capable of manufacturing standard PP product 15,000 squares per day

- Diameter & Length: Accept customization

- Finish-treatment: Calendering, Heat setting, Singeing

Features of polypropylene filter needle felt

⚫ Chemical stability: It has strong chemical stability and can work in various chemical environments without being corroded.

⚫ Abrasion resistance: Polypropylene fiber is relatively wear-resistant, so that the filter needle felt can maintain good performance in long-term use.

⚫ Low water absorption: It has very low water absorption, so it maintains stable filtration performance even in wet conditions.

⚫ Dimensional Stability: It is less sensitive to changes in temperature and humidity, which helps filter needle felt maintain stable dimensions and performance in various environments.

⚫ Ease of Cleaning: Since it does not pick up contaminants easily, it is relatively easy to clean.

Name and Features

Acrylic needle punched felt is one of the middle temperature resistance materials used to make filter bags, which has good hydrolytic stability.

Features

The continuous working temperature is 130-135 degrees, and the moment does not exceed 140 degrees.

Good acid and alkali resistance, PH value between 3-11.

The relative humidity is less than 30%, pay attention to oxidation.

Categories: Needle Punched Felts, Nonwoven Filter Fabric

Acrylic needle felt is a kind of fine fiber cloth using non-woven needle punching technology. The acrylic fibers are arranged in a staggered manner, the gaps are evenly distributed and large, the air permeability is good, and the chemical resistance is stable. It can not only filter normal temperature gas, but also filter medium temperature gas (150°C), it is an ideal choice for filtering acid, alkali and corrosive gases. Compared with polyester needle felt, the biggest feature of acrylic is that it has better hydrolysis resistance than polyester needle felt.

PP/Polypropylene Properties

| Material | Working Temperature |

Instant Temperature |

Abrasion Resistance |

Hydrolysis Resistance |

Acid Resistance |

Alkali Resistance |

Oxidation Resistance |

| PP Needle Felt | 60℃ | 100℃ | Excellent | Middle | Good | Middle | Middle |

Post-treatment

For PP/Polypropylene needle punched felt, we can treat it with different post-processing according to different working conditions. There are mainly the following post-processing treatments:

- PTFE Membrane

- Water&Oil repellent

Shapes and Types

PP/Polypropylene needle felt can be made into different types of filter bags, which can be mainly divided into the following three types according to different shapes:

Application

Polypropylene filter needle felt is widely used in gas and liquid filtration in industrial fields, including water treatment, chemical industry, food processing, pharmaceutical, mining and other industries. It can be used to filter particles, sediments, suspended solids, microorganisms, etc., to ensure cleanliness and safety in the production process.

Production line for example