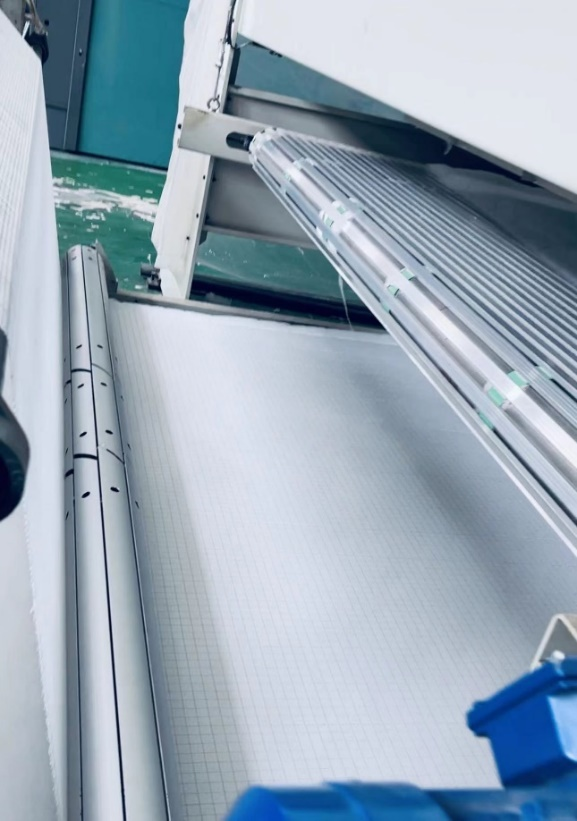

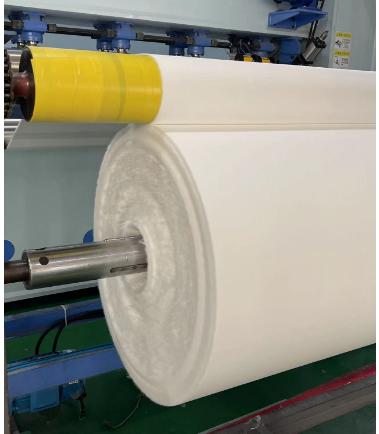

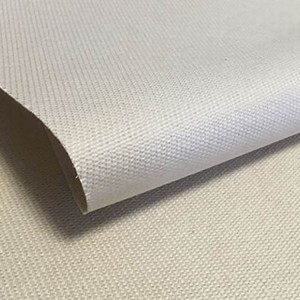

PE felt Cloth

Parameters

| Parameters Representation | ||

| Reference Information | parameters | |

| Product Name | Polyester Needle Punched Felt Cloth | |

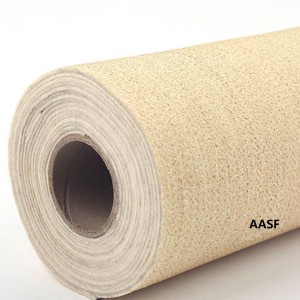

| Product Code | AASF-PE550 | |

| Physical properties | ||

| Weave method | needle felt | |

| Thickness | 1.8-2.2mm | |

| Weight range | 100-550 g/m² | |

| Width | 1.8m-2.2m | |

| Loss on Ignition (%) | ≥10 | |

| Chemical Finish | singe and calendeing and heat setting | |

| Air Permeability (L/m²S@200Pa) | 30- 80 | |

| Tensile strength( N/5cm ) | Warp | ≥1200 |

| Weft | ≥1300 | |

| Tensile elongation(%) | Warp | ≤35 |

| Weft | ≤50 | |

| Temperature | ||

| Continues temperature | 80 C° | |

| Instant temperature | 130 C° | |

POLYESTER/ PE NEEDLE PUNCHED FELT CLOTH

Specifications

Width: ≤2.2 m

Thickness: 1.7 mm

Weight: 300 -650g/m2 ±10%

Diameter & Length: accept customization.

Finish-treatment: Calendering, Heat setting, Singeing.

The capable of manufacturing 15,000 square meters per day (standard PE product). You can choose pure PE needle felt, PE blending needle felt, anti-static needle felt and water and oil proof needle felt. We also have SGS Qualifications of PE series product.

Post-Treatment

Polyester needle punched felt is one of the most common materials used to make filter bags. For polyester needle punched felt, we can treat it with different post-processing according to different working conditions. There are mainly the following post-processing treatments:

Anti-Static (line type, cross line type, blend type)

Anti-Spark

Water&Oil Repellent

Anti-Abrasion (Acrylic coating)

PTFE Membrane

PTFE Impregnation

Shapes and Types

Polyester needle felt can be made into different types of filter bags, which can be mainly divided into the following three types according to different shapes:

Round type

Flat type

Star/pleated type

According to different working principles, polyester needle felt can also be made into the following three filter bags:

Pulse jet filter bag

Reverse air filter bag

Shaker filter bag

Features

The continuous working temperature is 130-135 degrees, and the moment does not exceed 140 degrees.

Good acid and alkali resistance, PH value between 3-11.

The relative humidity is less than 30%, pay attention to oxidation.

Categories: Needle Punched Felts, Nonwoven Filter Fabric

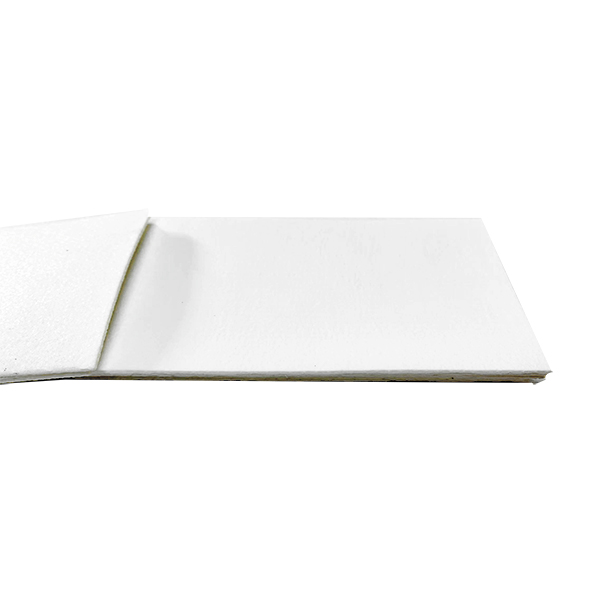

Acrylic needle felt is a kind of fine fiber cloth using non-woven needle punching technology. The acrylic fibers are arranged in a staggered manner, the gaps are evenly distributed and large, the air permeability is good, and the chemical resistance is stable. It can not only filter normal temperature gas, but also filter medium temperature gas (150°C), it is an ideal choice for filtering acid, alkali and corrosive gases. Compared with polyester needle felt, the biggest feature of acrylic is that it has better hydrolysis resistance than polyester needle felt.

Acrylic Properties

| Material | Working Temperature |

Instant Temperature |

Abrasion Resistance |

Hydrolysis Resistance |

Acid Resistance |

Alkali Resistance |

Oxidation Resistance |

| Acrylic Needle Felt |

120℃ | 140℃ | Good | Good | Excellent | Excellent | Good |

Post-treatment:

For acrylic needle punched felt, we can treat it with different post-processing according to different working conditions. There are mainly the following post

processing treatments:

Anti-Static (line type, cross line type, blend type)

Waterproof and oilproof

PTFE Membrane

Shapes and Types:

Acrylic needle felt can be made into different types of filter bags, which can be mainly divided into the following three types according to different shapes:

Round type

Flat type

Pleated Polyester Filter Bag

Star/Pleated Type

Application

Filter bags made of acrylic needle punched felt are widely used in many industries:

Cement Plant.

Lime Stone.

Asphalt Plant

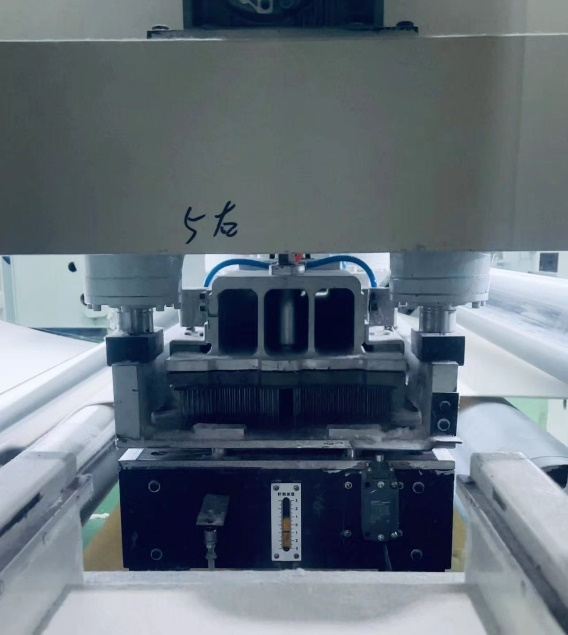

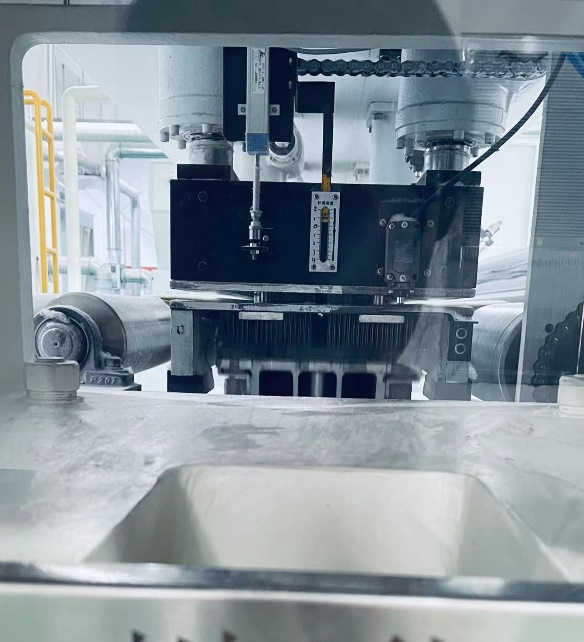

Production equipment