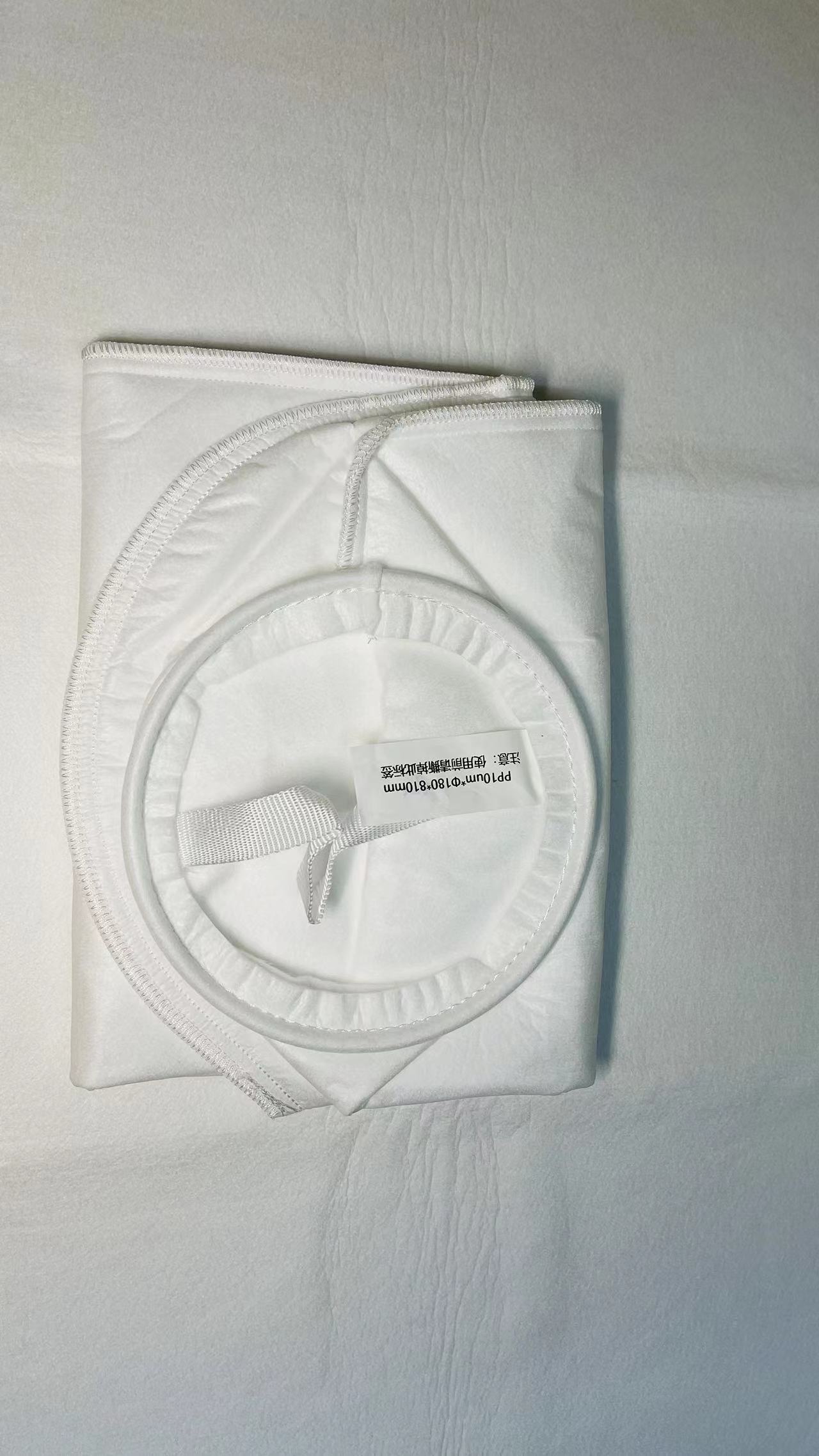

PE 10UM 180-810 polyester filter bag

PEΦ180*810*10UM

|

Product name: polyester filter bag |

||||

|

Filter material: polyester |

||||

|

Filter bag pressure: pressure difference ≤ 0.2MPa (replacement filter bag reference value) |

||||

|

Project |

Skills Requirement |

Detect |

Determination |

|

| Gram weight (g/mg²) |

370(±5%) |

375 |

Qualified |

|

| Thickness (mm) |

2.1(±5%) |

2.14 |

Qualified |

|

| Air permeability

(L/m².s) |

600(±25%) |

625 |

Qualified |

|

| Breaking Strength

(N) |

warp |

800(±2%) |

812 |

Qualified |

|

weft |

1100(±2%) |

1093 |

||

| Elongation |

warp |

35(≤%) |

35.5 |

Qualified |

|

weft |

50(≤%) |

49 |

||

| Temperature resistance(°C) |

≤130(°C) |

126(°C) |

Qualified |

|

| Exterior | No wrong warp, wrong weft, broken edges, smudges, scratches and holes | No wrong warp, wrong weft, broken edges, smudges, scratches and holes |

Qualified |

|

|

The fabric has passed the sanitary standard and testing standard:GB4806.7-2016 |

||||

|

Processing technology: all seams, O-galvanized ring |

||||

|

PEΦ180*810*10UM 880 pcs After passing the inspection, it will be given out of the factory and hereby certified. |

||||

The above products have been tested by the quality inspection department of Shanghai AASF Technology Co., Ltd., and they have all met the national industry standards and the relevant quality requirements promised by the company.

Polyester Filter Bag Factory Report

1.Use of filter bags:

The polyester filter bags produced by our company are made of high-elastic polyester yarn with uniform and stable pore size and accurate filtration precision. Before using this batch of filter bags, check the filter bag model first. Our company recommends soaking the filter bag to be used with the filtered liquid for about 3mim, and then put the filter bag into the support filter to open the filter bag and try to use it as much as possible. Fits to the wall of the support filter so that the filter bag can be evenly supported and protected when it is compressed. Then close the top cover of the filter tightly, and then start the machine according to the normal steps.

2.Replacement of filter bags:

When the polyester filter bag is used for a period of time, impurities are intercepted on the surface of the filter bag, blocking the filter bag, resulting in an increase in the pressure in the container, and the liquid output does not meet the customer's requirements. When the pressure difference of the filter bag reaches between 0.15MPa and 0.18MPa, the filter bag needs to be replaced, otherwise there is a danger of expanding the filter bag and supporting the filter screen. When replacing the filter bag, the upstream valve should be closed first, then the downstream valve should be closed, then the exhaust valve should be opened to discharge the pressure, and then the discharge valve should be opened. After the liquid has been discharged, the filter can be opened. Replace the filter bag with a new filter bag according to the usage method of the filter bag above. If the customer does not replace the filter bag according to this pressure standard, and the filter bag bursts, the customer needs to bear the consequences.

3. Cleaning of filter bags:

When cleaning the polyester filter bag, you can first turn the filter bag out to dump the residue in the bag, and then soak it in clean water for 5-10 minutes. After a period of time, grab the mouth and bottom of the bag with both hands in the water. Repeat the movement left and right and up and down, repeat several times, or put it in water and rub gently until it can be used again.

Trading information

| trading information | Logistic and delivery time | |||||||

| Name | Qty Piece/Pieces | FOB price | L/C,D/P,T/T,Western Union,Paypal | QTY Pieces |

Production time | Port | Monthly Piece/Pieces |

Packing |

| Liquid Filter bag 180*810, 10um | < 100 | 2.2 | L/C,D/P,T/T,Western Union,Paypal | 100 | 3 | Shanghai | 100000 | water proof bag and ctns |

| 100-1000 | 2 | |||||||

| >1000 | 1.5 | |||||||

Detail image