Other components

-

Hydraulic PU seals, industrial seals first choice, hot sales!

Hydraulic PU Seals: The Prime Choice for Industrial Sealing, Now Seeking Partners!

In the industrial sector, the stable operation of hydraulic systems is of utmost importance. Hydraulic PU seals, as the core components, are witnessing a surging market demand.These seals are suitable for various construction machinery such as excavators, loaders, as well as hydraulic pumps, hydraulic cylinders and other equipment. They can function perfectly in both harsh mining environments and high – precision industrial scenarios.With outstanding performance, the polyurethane material endows excellent wear resistance. It can withstand high – frequency friction, significantly extending the service life and reducing downtime for maintenance. Under complex working conditions, it has good chemical stability against hydraulic oil and can resist external corrosion, ensuring reliable sealing.By promoting on the platform, we can precisely reach industrial customers. We sincerely invite merchants to cooperate. Leverage the platform’s traffic to enhance product visibility and explore a vast market. Let’s work hand in hand for a win – win situation and ensure the efficient operation of the industrial sector. -

What is the specific working principle of pulse valve coil?

The working principle of the 24V pulse valve coil mainly involves the interaction between electricity and magnetism. Here is a detailed explanation:

- Electromagnetic induction: The pulse valve coil is essentially a solenoid, which is made of many turns of copper wire wound around a core. When a 24V alternating current is applied to the coil, according to Faraday’s law of electromagnetic induction, an alternating magnetic field is generated around the coil. The strength and direction of this magnetic field change with the frequency of the alternating current.

- Magnetic force generation: The core inside the coil is usually made of a ferromagnetic material such as iron. When the coil is energized, the core is magnetized by the magnetic field, which significantly enhances the magnetic field intensity. This strong magnetic field exerts a magnetic force on the movable parts of the pulse valve, such as the armature.

- Valve actuation: The magnetic force causes the armature to move. When the current is turned on, the magnetic force attracts the armature, which in turn opens the valve to allow the fluid (gas or liquid) to pass through. When the current is cut off, the magnetic field disappears, and the armature returns to its original position under the action of a spring or other restoring force, closing the valve and stopping the fluid flow. By controlling the on – off time of the current, the opening and closing time of the pulse valve can be accurately controlled, thereby achieving precise control of the fluid flow rate and pressure in the filtering and purifying device.

-

The customized 220V pulse valve coil is used for the filtering and purifying device parts

The customized 220V pulse valve coil is a crucial component within the filtering and purifying device. When an electrical current is applied to this coil, it generates a powerful magnetic field. This magnetic field, in turn, acts as the driving force behind the operation of the pulse valve.

During the normal operation of the filtering and purifying device, the pulse valve coil plays a key role in controlling the flow of gas or liquid. It enables the rapid opening and closing of the pulse valve. For instance, in a dust – collecting filtering system, when the filter elements become clogged with contaminants, the pulse valve coil receives an electrical signal. This signal activates the coil, causing the pulse valve to open suddenly. High – pressure air or cleaning fluid then rushes through the opened valve, forcefully blasting away the accumulated dust and debris from the filter elements. This timely and efficient cleaning action ensures that the filter elements can maintain their high – performance filtering capabilities, effectively purifying the air or liquid passing through the device. In essence, the customized 220V pulse valve coil is the core element that guarantees the smooth operation and continuous purification efficiency of the filtering and purifying device parts.

-

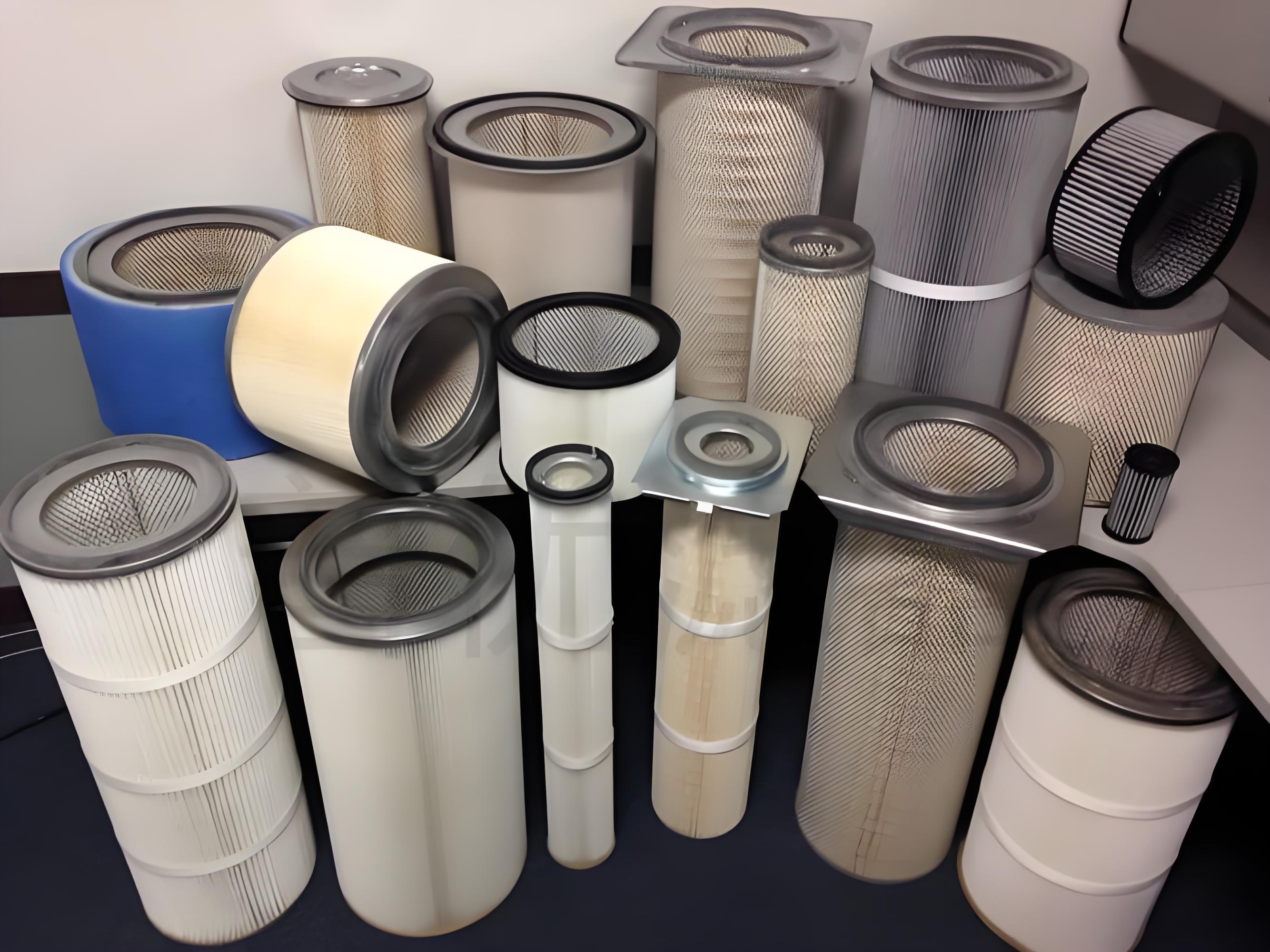

Custom Rubber Head Filter Cartridge

A custom rubber head filter cartridge is a specialized filtration component designed and manufactured according to specific customer requirements. The rubber head of this filter cartridge plays multiple important roles. Firstly, it can provide a good seal when installed in the filtration system, preventing the leakage of the fluid being filtered. The rubber material is often chosen for its excellent flexibility and sealing properties, which allow it to adapt to different connection interfaces.Secondly, the rubber head can also enhance the mechanical strength and durability of the cartridge connection part, ensuring that the filter cartridge remains stable during the filtration process. In terms of the filtering part of the cartridge, different filter media can be selected according to the characteristics of the fluid, such as the size of impurities, the chemical properties of the fluid, etc. This enables the custom rubber head filter cartridge to achieve precise and efficient filtration for various applications, including but not limited to water treatment, chemical industry, and food processing.It can be customized in terms of dimensions, filtration accuracy, and the type of rubber used for the head, meeting the diverse needs of different industries and specific working conditions. -

ndustrial dust removal, customized rubber filter element

Manufacturing Process

- Material Selection: The rubber head is typically made of high – quality rubber materials such as nitrile rubber, fluororubber, or ethylene – propylene rubber, which are chosen based on factors like the operating environment, temperature range, and chemical compatibility with the fluid being filtered. For the filter element, materials like cellulose fiber, glass fiber, stainless – steel wire mesh, and sintered felt are often used. These materials offer different filtration precisions and chemical resistances to meet various filtration requirements.

- Molding and Assembly: The rubber head is formed through a molding process to ensure a precise shape and size that matches the filter cartridge. It is then carefully assembled with the filter element. The assembly process may involve techniques such as gluing, clamping, or welding to ensure a secure connection between the rubber head and the filter element, preventing any leakage or detachment during operation.

Advantages of Customization

- Meeting Specific Requirements: Custom rubber – head filter cartridges can be designed to meet the unique needs of different applications. For example, in some high – temperature industrial processes, a heat – resistant rubber head can be customized to ensure the cartridge’s stability and performance. In applications where the fluid contains corrosive substances, a chemically resistant rubber material can be selected for the head, and a corresponding anti – corrosion filter element can be used to enhance the cartridge’s overall durability and reliability.

- Improving Filtration Efficiency: By customizing the structure and parameters of the filter cartridge, such as the pore size of the filter element, the pleat design, and the flow – through area, the filtration efficiency can be optimized. For instance, in a water – treatment system that requires high – precision filtration, a custom – designed filter cartridge with a smaller pore size and a larger filtration area can be developed to effectively remove fine particles and impurities, improving the quality of the treated water.

Quality Control and Testing

- Performance Testing: Before leaving the factory, custom rubber – head filter cartridges undergo a series of strict performance tests. This includes testing the filtration efficiency to ensure that the cartridge can effectively remove impurities of a specific size from the fluid. The pressure – drop characteristics are also measured to ensure that the cartridge does not cause excessive pressure loss during operation, which could affect the normal operation of the entire system. Additionally, tests are conducted to evaluate the cartridge’s resistance to high temperatures, pressures, and chemical corrosion to ensure its reliability in different working conditions.

- Quality Assurance: Manufacturers usually implement a comprehensive quality – management system to ensure the quality of custom filter cartridges. This includes strict control over the raw – material procurement process to ensure that only high – quality materials are used. During the manufacturing process, each production step is closely monitored and inspected to detect and correct any potential quality issues in a timely manner. After production, random sampling inspections are carried out to ensure that each batch of filter cartridges meets the specified quality standards.

Application Examples

- Chemical Industry: In chemical – production processes, custom rubber – head filter cartridges are used to filter various chemical fluids, such as acids, alkalis, and organic solvents. The customized rubber head and filter element materials can resist the corrosion of these chemicals, ensuring the safe and stable operation of the filtration system. For example, in a pharmaceutical – manufacturing process, filter cartridges with high – precision filtration and sterile – resistant properties are required to ensure the quality of the final product.

- Automotive Industry: In the automotive – manufacturing process, custom rubber – head filter cartridges are used in engine – oil filtration systems, fuel – filtration systems, and air – filtration systems. The customized filter cartridges can meet the specific requirements of different automotive models and engine types, improving the performance and reliability of the vehicle’s filtration systems. For example, in high – performance engines, filter cartridges with better filtration efficiency and larger dirt – holding capacities are needed to ensure the cleanliness of the engine oil and the normal operation of the engine.

-

head of plunger set

Information Item code Parameters Size 1.5 inch Mode Solenoid plunge 1-1.5 type Type right angle type Spring materials 304ss Protection level IP 65 Efficiency Diaphragm 1 million strikes Valve body materials Excellent Ally Alminum Voltage 24VDC,110VAC, 220VAC Trading information Trading Information Logistic Description Piece/Pieces FOB Price Payment terms Quantity Pieces Time Port Monthly Piece/Pieces Packing Head of plunger for pulse... -

Venturi

Information Item Parameters Name: Venturi for bag filter Code): Venturi-200 Dimension(mm) 200*75*190 Material: carbon steel efficiency of Injection :+15%-30% guiding gas Temperature: 0℃-80℃ Surface treatment Electrical galvanized Trading information Trading Information Logistic Description Piece/Pieces FOB Price Payment terms Quantity Pieces Time Port Monthly Piece/Pieces Packing Venturi for bag filter >100 8 T/T,Western Union,Money... -

Suspension system parts

Information Item Parameters Materials Options 302ss Type Spring type Top design with neck-tube locked Body design Conical design Working condition To hanging filter bags Temperature ranges 10-200 degree Trading information Trading Information Logistic Description Piece/Pieces FOB Price Payment terms Quantity Pieces Time Port Monthly Piece/Pieces Packing Suspension system parts >100 8 T/T,Western Union,MoneyGram,Paypal 300 10 Shanghai 100000 ... -

Solenoid coil

This product is to use the enameled wire wounding on a hollow cylindrical skeleton, it’s external surface is made by plastic injection molding through making a coil assembly. Coil rear plug is exposed, which can be connected to the junction box as requested, generating a magnetic force after power. Currently the coils are widely used in electromagnetic pulse valve industry.

-

Nozzle

Information Item Parameters Code DQP-40, DQP-25 Dimension 56mmx74mmx110mm Materials PA/PPS Efficiency of Injection +15%~30% Weight 100g±5g Temperature 0℃-215℃ Trading information Trading Information Logistic Description Piece/Pieces FOB Price Payment terms Quantity Pieces Time Port Monthly Piece/Pieces Packing Nozzle for Sprayer on air tube >100 6 T/T,Western Union,MoneyGram,Paypal 300 10 Shanghai 100000 water proof bag and ctns 100-1000 5... -

Iron casting Venturi

Information Item Parameters Name: Venturi for bag filter Code): Venturi-185 Dimension(mm) 185*75*165 Material: Iron steel efficiency of Injection :+15%-30% guiding gas Temperature: 0℃-80℃ Surface treatment Electrical galvanized Trading information Trading Information Logistic Description Piece/Pieces FOB Price Payment terms Quantity Pieces Time Port Monthly Piece/Pieces Packing Venturi Casting type >100 8 T/T,Western Union,MoneyGram... -