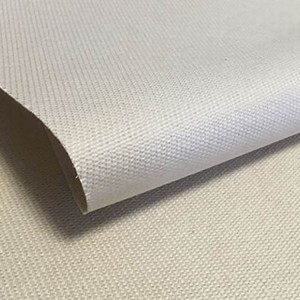

Mit Filter Cloth

MIT filter cloth is also called Middle Temperature resistance Fiber

Glass needle-punched filter felt which is a filter material with reasonable structure and good performance. PE combining Fiberglass has outstanding dimensional stability, high tensile strength at break, corrosion resistance, smooth surface, good water-repellent, breathable, easy cleaning, chemical stability. Fiberglass is used as raw material, and the carded chopped fiberglass is needle-punched. The fibers between the fiberglass and between the fiberglass and the base cloth are entangled with each other by mechanical methods to make a non-woven filter material.

Advantages of Fiberglass Needle-Punched Filter Felt

Temperature resistance: Glass fiber has high temperature resistance, so it can maintain stable performance in high temperature environment and is suitable for high temperature working conditions.

Chemically inert: It is inert to many chemical substances and not susceptible to corrosion, so it is suitable for handling various chemical liquids and gases.

| Product Name | Fiberglass PE needle felt 750g/m² | |

| Product Code | FB-PE750-MIT | |

| Physical properties | ||

| Fiber | fiberglass fiber and Polyester fiber | |

| Scrim | fiberglass yarn | |

| Weight | g/m² | 750 |

| Thickness | mm | 2,4 |

| Width | m | ≤2.2 |

| Finish treatment | PTFE impregnation | |

| Air permeability | l / m2 /S @200pa | 30 ~ 100 |

| Tensile strength | Warp (N/5×20cm) | 1300 |

| Weft(N/5×20cm) | 1500 | |

| Tensile elongation | Warp (%) | 8 |

| Weft (%) | 8 | |

| Temperature | ||

| Continue temperature | C° | 130 |

| Instant temperature | C° | 150 |

| Chemical Properties | ||

| Anti-acid | Good | |

| Anti-alkali | Good | |

| Anti-abrasion | Good | |

| Hydrolysis stability | Middle | |

Mechanical strength: Needle-punching process can form a strong mechanical connection between the fiber layers of the glass fiber felt, which improves the mechanical strength and durability of the filter felt.

Microfiltration: The diameter of the glass fiber is finer, which can produce a filter mat with a denser fiber structure, thereby achieving a more efficient microfiltration effect.

Adsorption performance: Due to the microstructure of the fiber surface, it has a certain adsorption capacity and can be used in some occasions that need to remove suspended particles and particles.

Physical Properties of Fiberglass Nonwoven Needle Filter Felt

Applications

Fiberglass needle-punched filter felts are widely used in the industrial field, mainly as filter materials for the separation, filtration and capture of liquid, gas and solid particles.

Air Filtration

Fiberglass needle-punched filter mats are often used in air filters to capture particles and particulates in the air to keep indoor air clean and purified, such as in homes, commercial buildings, medical institutions, etc.

Liquid Filtration

It can be used in liquid filtration, such as water treatment, chemical production, food processing and other fields, to remove suspended particles, impurities, pollutants, etc. to obtain pure liquid products.

Petrochemical industry

In the petrochemical industry, it can be used in the production process of petroleum and chemical products to help separate and purify raw materials or products.

Metallurgical industry

In the field of metallurgy, it can be used in steelmaking, ironmaking and other processes to remove slag and impurities and ensure the purity and quality of metals.

Environmental protection equipment

It can be applied to environmental protection equipment such as flue gas desulfurization and denitrification to help remove harmful substances in exhaust gas and reduce environmental pollution.

Food processing

In the field of food processing, it can be used in the production process of beverages, edible oils and other products to remove impurities and particles to ensure the hygiene and quality of food.

Medicine and pharmacy

It is used in the pharmaceutical field to filter liquid medicines and solutions to ensure the purity and stability of medicines.

Sewage treatment

It can be used in sewage treatment to remove solid particles and suspended matter in wastewater, so that wastewater can be purified.