FMS Cloth

Parameter

| Parameters Representation | ||

| Reference Information | parameters | |

| Product Name | FMS Needle Felt Cloth | |

| Product Code | AASF-FMS850M-Cloth | |

| Physical properties | ||

| Weave method | needle felt | |

| Thickness | 2.5 | |

| Weight | 850 g/m² | |

| Width | 1.8m-2.2m | |

| Loss on Ignition (%) | ≥10 | |

| Chemical Finish | PTFE membrane | |

| Air Permeability (L/m²S@200Pa) | 30- 80 | |

| Tensile strength( N/5cm ) | Warp | 1300 |

| Weft | 1500 | |

| Tensile elongation(%) | Warp | 8 |

| Weft | 8 | |

| Temperature | ||

| Continues temperature | 240 C° | |

| Instant temperature | 280 C° | |

FMS needle felt has excellent anti-acid and anti-alkali performance, using Fiberglass compound staple fiber, P84fiber, Nomex fiber, enabling it to last more than 4500 hours.

Supply Ability: 5000 m²/day

Long Working Life: More than 4500 hours

Filtration Velocity: Up to 1.0 m/min

Temperature-Resistance: Max. Temp. 280℃

Finish-treatment: Calendering, Heat setting, Singeing

Customization accepted.

FMS needle felt has excellent anti-acid and anti-alkali performance, using Fiberglass compound staple fiber, P84fiber, Nomex fiber, enabling it to last more than 4500 hours.

Supply Ability: 5000 m²/day

Long Working Life: More than 4500 hours

Filtration Velocity: Up to 1.0 m/min

Temperature-Resistance: Max. Temp. 280℃

Finish-treatment: Calendering, Heat setting, Singeing

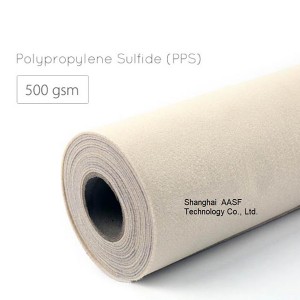

Physical Properties and Chemical Properties

| Product Name | FMS needle felt 850g/m² | |

| Product Code | ES-FMS850TFI | |

| Physical properties | ||

| Fiber | Mixed fiber | |

| Scrim | fiberglass yarn | |

| Weight | g/m² | 850 |

| Thickness | mm | 2,4 |

| Width | m | ≤2.2 |

| Finish treatment | PTFE impregnation | |

| Air permeability | l / m2 / s @200pa | 200 ~ 300 |

| Tensile strength | Warp (N/5×20cm) | 1300 |

| Weft(N/5×20cm) | 1500 | |

| Tensile elongation | Warp (%) | 8 |

| Weft (%) | 8 | |

| Temperature | ||

| Continue temperature | C° | 240 |

| Instant temperature | C° | 280 |

| Chemical Properties | ||

| Anti-acid | Good | |

| Anti-alkali | Good | |

| Anti-abrasion | Good | |

| Hydrolysis stability | Middle | |

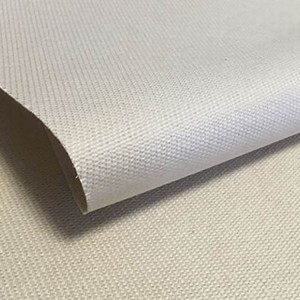

Post-treatment

For FMS needle punched felt, we can treat it with different post-processing according to different working conditions. There are mainly the following post-processing treatments:

PTFE Impregnation

PTFE Membrane

Shapes and Types

FMS needle felt can be made into different types of filter bags, which can be mainly divided into the following three types according to different shapes:

Roundtype

Flat type

Star/pleated type

Applications

Widely used in steel, nonferrous metallurgy, chemical industry, carbon black, building materials, electric power and other departments.