Filter bag

-

Polyester Filter Bags

Based on the provided search resources, here is a comprehensive summary of polyester filter bags:1. Materials and Characteristics

- Materials: Polyester filter bags are primarily made from polyester staple fibers or filaments, processed through needle-punching, weaving, or other techniques. Some products undergo post-treatment such as heat setting, singeing, calendering, PTFE impregnation, or water/oil repellent finishes to enhance performance.

- Key Features:

- Excellent Filtration: High porosity and 透气性 ensure efficient dust collection (e.g., 208 polyester flannel bags achieve a dust removal rate of 99.99%).

- Durability: High abrasion resistance and long service life; smooth surfaces facilitate easy ash cleaning, reducing dust adhesion and operational resistance.

- Temperature Resistance: Continuous operating temperature typically ranges from 80°C to 130°C (depending on the product model), with a short-term peak temperature of up to 150°C.

- Chemical Tolerance: Moderate resistance to acids and alkalis, suitable for various industrial environments.

2. Classification and Types

- By Raw Material:

- Polyester Staple Fiber Filter Bags: Good breathability, suitable for general dust removal.

- Polyester Filament Filter Bags: Higher strength and longer lifespan.

- By Weaving Method:

- Woven Filter Bags: Tightly structured, suitable for high-temperature and high-pressure environments (e.g., 208 polyester woven filter bags).

- Needle-Punched Felt Filter Bags: High porosity and superior filtration efficiency, making them the mainstream choice.

- By Function:

- Anti-Static Filter Bags: Incorporate anti-static fibers to prevent electrostatic accumulation, ideal for explosive dust environments.

- Water and Oil Repellent Filter Bags: Surface-treated to resist water and oil penetration, suitable for wet or oily dust.

- Membrane Filter Bags: Combined with microporous membranes to enhance capture of fine particles.

3. Technical Parameters (Typical Product Example)

- Fiber Composition: Polyester staple fiber

- Base Cloth Composition: Polyester filament

- Grammage: 500g/m²

- Thickness: 1.70mm

- Tensile Strength: Warp ≥1200N/5cm, Weft ≥1500N/5cm

- Air Permeability: 14 m³/㎡·min

- Continuous Operating Temperature: 130°C (some products specify 80°C; confirm with specific specifications)

- Short-Term Peak Temperature: 150°C

4. Application Fields

Polyester filter bags are widely used in:- Heavy Industries: Dust removal systems in steel, power, cement, chemical, and smelting industries.

- Environmental Equipment: Bag dust collectors for treating industrial dusty gases.

- Other Fields: Petroleum, mining, waste incineration, pharmaceuticals, food processing, and other scenarios requiring filtration.

5. Usage Precautions

- Installation and Maintenance:

- Ensure smooth water distribution systems and uniform filter media 铺装.

- Avoid overly loose or tight filter bags to prevent dust accumulation or damage.

- Regularly inspect filter bags for wear and replace damaged ones promptly.

- Temperature Control:

- Avoid prolonged operation above the rated temperature; short-term peaks should not exceed 150°C.

- In high-temperature and high-humidity environments, use water/oil repellent or membrane filter bags to prevent condensation and clogging.

- Airflow Adjustment:

- Ensure uniform air intake to avoid localized impact damage to filter bags.

- For high-flow conditions, equip automatic flow control systems to stabilize gas volume.

6. Conclusion

Polyester filter bags are a mainstream choice in industrial dust removal and filtration due to their excellent filtration efficiency, durability, and adaptability. Selection should consider specific working conditions (e.g., temperature, dust properties, humidity), and proper installation and maintenance are crucial to ensure efficient operation and extend service life. -

PPS/PTFE650 filter bag

The PPS/PTFE650 filter bag features the following specifications:

- Material: Fiber composed of PPS+PTFE, scrim (base fabric) made of PTFE.

- Physical Properties:

- Weight: 650 g/㎡ (compliant with ISO 9073-1).

- Thickness: 1.6 mm.

- Air Permeability: 150–250 l/㎡·s@200Pa (per ISO 9237).

- Mechanical Performance:

- Tensile Strength (ISO 9073-3, sample size 200/50mm): Warp ≥1100N, Weft ≥900N.

- Tensile Elongation (ISO 9073-3): Warp <35%, Weft <45%.

- Thermal Properties:Surface Treatment: Includes singe, calendering, heat setting, and PTFE dipping processes.

- Working Temperature: Continuous use at 190℃, instant tolerance at 220℃.

- Heat Shrinkage: 3% at 220℃.

-

FILTER BAG:POLYAMIDE (PI) NEEDLEFELT

we have polyester and high temperature resistance filter sleeve/filter bagsneedle felt, punch felt, singe, calendaring, heat settingTypes:Anti-static, water&oilresistance, PTFE membrance

Item Standard Metric Value Imperial Value Area Weight EN12127 550±25g/m² 16.3±0.75oz/yd² Thickness EN ISO 9073/2 2.0±0.2mm 0.079±0.007in Composition — Fiber: Polyamide (PI)

Scrim: PTFE— Finish — Heat-set, Calender, Surface Treatment with PTFE Bath — Property Index Standard Longitudinal Cross Tensile Strength (5×20cm) GB/T 3923.1-2013 ≥900N ≥1200N Elongation GB/T 3923.1-2013 ≤35% ≤50% Thermal Stability (Shrinkage at 260℃ 24h) GB/T 6719-2009 ≤1.5% ≤1% Air Permeability (at 200Pa) GB/T 5453 100-180 l/dm²·min — Fiber Properties and Operating Temperature

- Fiber Properties: Polyamide (PI)/PTFE

- Operating Temperature (Dry):

- Continuous: 260℃ Max (500℉ Max)

- Peaks: 280℃ Max (536℉ Max)

Remarks

- All data are expressed as typical values. This technical data is subject to change.

-

FILTER CLOTH :WOVEN-FIBER GLASS w PTFE Membrane

we have polyester and high temperature resistance filter sleeve/filter bagsneedle felt, punch felt, singe, calendaring, heat settingTypes:Anti-static, water&oilresistance, PTFE membrance

item Standard Parameter value AREA WEIGHT(面积重量) EN12127 750±22.5g/m²(19.08±0.65oz/yd²) THICKNESS(厚度) EN ISO 9073/2 0.7-1.1mm(0.027–0.043in) WEAVE(编织方式) — DOUBLE TWILL(双斜纹) FINISH(后整理) — PTFE MEMBRANE(覆 PTFE 膜) TENSILE STRENGTH(拉伸强度,5×20cm) GB/T 3923.1-2013 ≥3400N(另有≥2400N 未明确标准) ELONGATION(伸长率) GB/T 3923.1-2013 ≤8% THERMAL STABILITY(热稳定性,260℃ 2h 收缩率) GB/T 6719-2009 ≤1.5%(另有≤1% 未明确标准) AIR PERMEABILITY(透气率,200Pa) GB/T 5453 12-54 l/dm²min OPERATING TEMPERATURE(工作温度,干燥) — CONTINUOUS(连续):260℃Max(500℉Max)

PEAKS(峰值):280℃Max(536℉Max)Please contact us if necessary

-

Environmental defender:PTFE filter bag

Details about PTFE filter bag finishing:

First, material characteristics

High temperature resistance: continuous operation at 240 ° C, instant resistance to 260 ° C high temperature.

Corrosion resistance: Almost all acid and alkali resistance, organic solvents and chemical corrosion, chemical stability is very high.

Low friction coefficient: smooth surface, good self-moistening, not easy to adhere to impurities, easy to clean.

Other characteristics: UV resistance, no moisture absorption, but the wear resistance is general, the filter bag frame requires high finish.

2. Technical parameters (Take mainstream products as an example)

Fiber/substrate: 100% PTFE

Square gram weight: 750g/m²

Thickness: 1.1mm

Air permeability: 90-100L/㎡·min

Fracture strength: longitudinal and transverse ≥450N/5cm

Thermal shrinkage rate: 3% shrinkage at 260℃ for 90 minutes

Continuous operating temperature: 240℃, instant temperature 260℃

3. Application fields

Industrial flue gas treatment: coal-fired boilers, waste incineration, carbon black production, titanium dioxide production, etc.

Chemical industry: Filter acids, alkalis, solvents and corrosive chemicals.

Pharmaceutical and Food: Purification of pharmaceuticals, clarification of beverages/dairy products, solid-liquid separation in food processing.

Environmental protection: sewage treatment, waste gas treatment, air purification.

Electronics industry: high purity gas/liquid filtration, clean room air purification.

Other: petrochemical, paint, ink, resin production, etc.

4. Analysis of advantages and disadvantages

Advantages:

Chemical stability and high temperature resistance in extreme environments.

High filtration accuracy (up to 0.1-100 microns), high efficiency.

Long service life, relatively low maintenance costs.

Cons:

The cost is high and the initial investment is large.

Poor wear resistance, pay attention to the filter bag frame finish.

Five, use and installation precautions

Before installation:

Check whether the filter bag is damaged and clean the surface of dust and impurities.

Make sure the filter bag fits the frame tightly to avoid leaks.

In use:

Control the temperature below 260 ° C to avoid high temperature deformation.

Prevent the impact of high-speed air flow, reduce the vibration damage of filter bag.

When dealing with low temperature and high humidity gas, anti-condensation measures (such as heating and dehumidifying) are required.

Maintenance:

Check the wear of the filter bag regularly and replace it in time.

Use an electric vacuum cleaner and avoid washing.

Keep dry and ventilated when storing away from direct sunlight. -

The following are successful application cases of dust filter bags in different industries

The following are successful application cases of dust filter bags in different industries, demonstrating their efficient dust removal performance and environmental value:

1. Mining industry: efficient control of dust pollution

Iron ore crushing section: a large mining enterprise in the crushing and screening links to introduce cloth bag dust collector, through the needle felt filter bag to capture fine dust, dust emission concentration is reduced to the national standard, improve the working environment, reduce the risk of occupational diseases.

Gold mine tailings treatment: gold mine enterprises use customized filter bags to treat the dust in the tailings transportation, combined with the pulse ash cleaning system, dust capture rate of more than 99%, effectively protect the surrounding ecological environment, enhance the enterprise environmental protection image.

2. High temperature industry: cope with complex conditions

Glass manufacturing: A glass factory uses coated PTFE needled felt filter bags to treat high temperature flue gas (260 ° C), which not only achieves dust emission concentration below 10mg/m³, but also reduces the filter bag replacement frequency and reduces maintenance costs by 30%.

Coal-fired boiler: A power plant uses aramid based filter bag, stable operation in high temperature and high humidity environment, PM2.5 capture efficiency of 99.99%, helping to achieve ultra-low emission goal.

3. Building materials and chemical industry: breaking through technical barriers

Cement factory: Spina felt filter bag developed by a company in Jiangsu improves filtration accuracy through high-pressure water flow process, reducing dust emission from 50mg/m³ to less than 10mg/m³, and increasing material utilization rate by 20%, breaking foreign technology monopoly.

Chemical reactor: A chemical plant uses PTFE coated filter bags to treat the tail gas containing corrosive gases, and the filter bag life is extended to more than 3 years, while achieving efficient recovery of catalyst powder.

4. Agriculture and people’s livelihood: Meet the needs of special scenarios

Straw crushing: The cloth bag energy-saving vacuum cleaner developed by Zhoukou enterprises is applied to the peanut seedling crushing equipment, which completely solves the problem of dust pollution, has been certified by the national patent, and is called “dust removal magic weapon” by farmers.

Cigarette production: A cigarette factory in Chongqing has extended the replacement cycle of the filter bag by 50% by reforming the anti-clogging device of the pressure differential meter pressure tube combined with the anti-corrosion filter bag, and the transformation cost of a single set of equipment is only 8 yuan.

5. Environmental technology innovation: intelligent upgrade

Quarry comprehensive application: A quarry in the crushing, screening, transportation links to deploy intelligent bag dust removal system, real-time monitoring of filter bag status through the pressure sensor, combined with AI algorithm to optimize the cleaning cycle, dust concentration reduced by 80%, equipment operating efficiency increased by 25%.

Circular economy practice: An environmental protection company in Xiamen developed a high-temperature silicone sealing process, which increased the service life of the filter bag to 4 years, successfully applied to a number of large projects at home and abroad (such as Turkey waste incineration plant), and the material loss rate was reduced from 2% to 1%.

Sum up

Through material innovation (such as PTFE, arnylon, spina felt) and intelligent design, dust filter bags have achieved significant results in mining, electric power, chemical industry, agriculture and other fields, not only to meet the requirements of environmental regulations, but also to reduce costs and increase efficiency for enterprises. In the future, with the development of filter bag technology in the direction of high precision, long life and intelligence, its application scenarios will be further expanded to help achieve the goal of global carbon neutrality. -

The use of dust filter bag

Dust filter bag is the core component of industrial dust removal system, mainly used to capture and separate dust particles in the air, to ensure the production environment clean and efficient operation of equipment. The following are typical application scenarios and key advantages:

1. Application field

Steel/Metallurgy: electric furnace, blast furnace dust removal, capture metal oxide dust

Chemical: reaction kettle tail gas treatment, filter catalyst powder

Electricity: coal-fired boiler flue gas treatment, to achieve PM2.5 emission standards

Building materials: cement kiln tail dust removal, control particulate emission concentration

Food and medicine: sterile workshop air purification, to ensure the cleanliness of the production environment

2. Core strengths

High efficiency filtration: Using needle felt/film coating process, filtration efficiency of 99.99%

Energy saving and consumption reduction: stable air permeability, reduce the system operating resistance

High temperature resistance: can withstand 260℃ continuous operation (such as glass fiber material)

Long life design: corrosion resistance, wear resistance, life of 2-4 years

Environmental protection features: Support dust recycling, meet the requirements of carbon neutrality

3. Select recommendations

Choose the material according to the working condition: such as PPS for sulfur-containing smoke, PTFE for strong acid environment

Attention to filtration accuracy: sub-micron dust needs to select microporous membrane composite filter material

Matching cleaning method: It is recommended to select filter material with strong folding resistance in pulse cleaning system

4. Maintain key points

Check the damage regularly to avoid powder leakage affecting the system efficiency

Control inlet dust concentration, prolong service life

Clean up the residual dust in time during shutdown to prevent compaction

Modern industrial dust removal systems are developing intelligentiously, some filter bags have integrated pressure sensors, which can monitor the filter status in real time, and optimize the cleaning cycle with AI algorithms to further improve operating efficiency. -

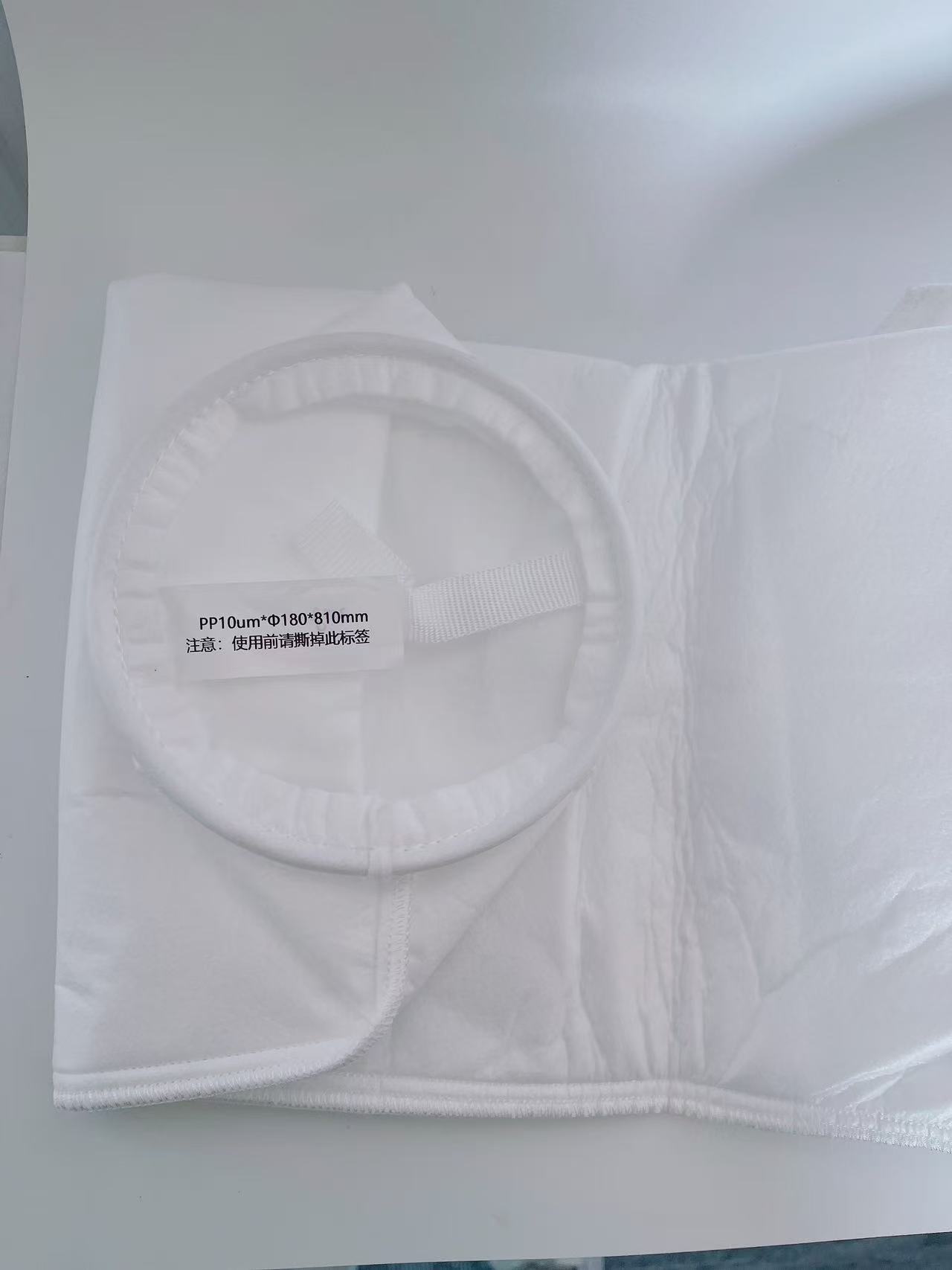

How the water filter bag works?

Working principle

The multi-bag filter introduces the water to be filtered into the filter shell through the pump, and the water enters the filter bag. Under the action of pressure, the water passes through the microhole of the filter bag, and the impurities are trapped in the filter bag, so as to achieve the filtration and purification of water.

Component introduction

Filter bag: Made of polypropylene, with different micron grades, such as 0.2 micron, 5 micron, 10 micron, 100 micron, can be selected according to filtration needs. The lower the micron number, the finer the particles that can be filtered out, and the higher the filtration accuracy.

Multi-bag filter: usually made of corrosion-resistant materials such as stainless steel, it can accommodate multiple filter bags to increase the filtration area and flow rate and improve filtration efficiency.

Material property

Polypropylene (PP) : good chemical stability, acid, alkali, organic solvent resistance; With good mechanical strength and wear resistance, the price is relatively low, cost-effective.

Polyethylene (PE) : strong chemical resistance, good flexibility, can adapt to a certain degree of deformation and vibration; Good low temperature resistance, can still maintain good performance in cold environment.

Polytetrafluoroethylene (PTFE) : has very high chemical stability, almost no reaction with any chemical substances; Excellent resistance to high temperature and low temperature; Smooth surface, not easy to absorb impurities, easy to clean.

Nylon (Nylon) : high strength, good toughness, can withstand greater pressure and tension; High filtration accuracy, can effectively remove fine particles and impurities in water. -

PP PE PTFE Nylon Water Filtration Multi Bag Filter Machine 0.2/5/10/100 Micron Polypropylene Liquid Filter Bag

In the delicate field of water filtration, our filter bags are well deserved experts. Using the scientific ratio of P, PE, PTFE, nylon multiple materials, combined with the precise aperture design of 0.2 to 100 microns, each polypropylene filter bag has been created by strict technology. From food and beverage production lines to pharmaceutical laboratories, from chemical raw materials purification to daily drinking water purification, it can accurately intercept all kinds of impurities in the water, efficiently remove microorganisms, colloids and fine particles, with excellent filtration performance, for your water safety and product quality layers of control, setting a new benchmark for industry quality.

vividness

Imagine that every drop of water is a small world, and our water filter bag is the magical guardian of this world. P, PE, PTFE, nylon interwoven into a tough and delicate “magic net”, polypropylene filter bag as with a sharp eye, whether it is 0.2 microns of tiny dust, or 100 microns of larger impurities, all do not want to escape its “pursuit”. When the water flows through the filter bag, it is like experiencing a wonderful purification journey, the impurities are stopped one by one, and the outflow of water becomes crystal clear, like a mountain spring, bringing you the purest water experience.

Affective resonance wind

Water is the source of life and the key to quality of life. We know your desire for pure water quality, so we have carefully developed this water filter bag. It is based on P, PE, PTFE and nylon, and is equipped with polypropylene filter bags of different microns to protect every water use. Whether it is the daily drinking water prepared for the family, or the safe choice of brewing milk powder for the child, it can ensure that the water quality is pure, so that you can drink every mouthful of water with confidence, every use of peace of mind, with pure water, nourish the happy life of you and your family. -

-

What is a water filter bag?

A water filter bag is a filtration device mainly used to remove impurities, suspended solids and other substances in water to purify water quality. The following is a detailed introduction:

Structure and Material

- Structure: Generally, a water filter bag is a bag-shaped structure with an opening at one end. The opening is usually designed with a ring or other fixing device for easy installation and connection to the water filtration system.

- Materials: It is often made of various filter materials such as polyester, polypropylene and nylon. These materials have different filtration precisions and chemical resistances to meet different filtration requirements. For example, polyester filter bags have good strength and chemical stability, while polypropylene filter bags are known for their excellent acid and alkali resistance.

Working Principle

- The water to be filtered enters the filter bag through the inlet. As the water passes through the filter material of the bag, impurities, suspended solids, and particulate matter in the water are trapped by the filter material due to the sieving and adsorption effects. The filtered water then passes through the filter bag and flows out through the outlet, thus achieving the purpose of water purification. The filtration precision of the filter bag can range from a few microns to hundreds of microns, depending on the specific application and the fineness of the filter material.

Applications

- Industrial Fields: In industrial water treatment, such as in the chemical, electroplating, and pharmaceutical industries, water filter bags are used to remove impurities in process water to ensure the quality of products and the normal operation of production equipment. They can also be used in industrial wastewater treatment to reduce the content of pollutants in the wastewater before it is discharged.

- Domestic Use: In household water purification systems, water filter bags are often used as the first stage of filtration to remove large particles of impurities, rust, and sediment in tap water, prolonging the service life of subsequent water purification equipment such as water purifiers and improving the quality of domestic water.

- Aquaculture: In aquaculture, water filter bags are used to filter pond water or circulating water in aquaculture systems to remove uneaten feed, fish feces and other impurities, maintaining good water quality and a suitable living environment for aquatic organisms.

- Swimming Pools: In swimming pool water treatment systems, water filter bags play a role in filtering out suspended matter, leaves and other impurities in the water to keep the pool water clean and clear and reduce the burden of disinfection and purification equipment.

-

Industrial dust filter bag, all kinds of materials

Unleash Precision Filtration with Our Industrial-Grade Filter Bags!

- Diverse Materials, Unrivaled Performance: Choose from high-quality polyester, nylon, and polypropylene. Each material is engineered to deliver exceptional filtration, whether it’s withstanding harsh chemicals (polypropylene) or providing excellent strength and durability (nylon and polyester).

- Ultra-Precise Filtration: With a wide spectrum of micron ratings available, our filter bags can trap particles of varying sizes. From the tiniest microparticles to larger debris, we’ve got you covered for any filtration need.

- Customizable for Your Convenience: Multiple top options, including ring, drawstring, and flange, ensure a perfect fit for your existing equipment. Tailor the filter bag to your specific setup effortlessly.

- Woven or Felt, Your Call: Our woven and felt materials offer different filtration advantages. Woven bags provide enhanced structural integrity, while felt bags offer higher filtration efficiency. Pick the one that suits your application best.

- Sizes Galore: Available in sizes #1, #2, #3, #4, our filter bags are adaptable to various filtration systems. No matter the scale of your operation, we have the right size for you.