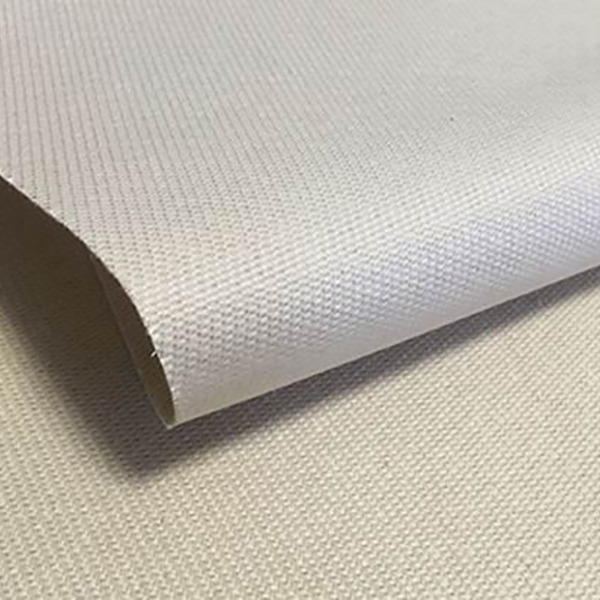

Fiberglass cloth

Features

⚫ High Temperature Resistance: 240-280℃

⚫ Excellent in Anti-Acid and Anti-Alkali.

⚫ Abrasion resistance, high tensile strength.

⚫ Long Service Life: >4500 hours

⚫ Low resistance of filtration.

⚫ Single fiber, high porosity, gas filtration resistance.

⚫ Can be used in a variety of complex situation and harsh environmental conditions.

⚫ Can be customized.

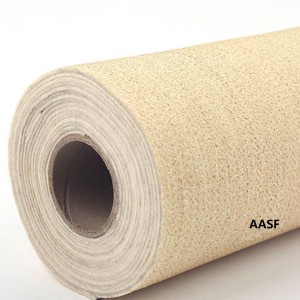

Properties of Non woven Fiberglass Filter Bag

| Fiber | fiberglass fiber | |

| Scrim | fiberglass yarn | |

| Weight | g/m² | 850 |

| Thickness | mm | 2,4 |

| Width | m | ≤2.2 |

| Finish treatment | PTFE impregnation | |

| Air permeability | l / m2 /S @200pa | 200 ~ 300 |

| Tensile strength | Warp (N/5×20cm) | 1300 |

| Weft(N/5×20cm) | 1500 | |

| Tensile elongation | Warp (%) | 8 |

| Weft (%) | 8 | |

| Temperature | ||

| Continue temperature | C° | 230 |

| Instant temperature | C° | 250 |

| Chemical Properties | ||

| Anti-acid | Good | |

| Anti-alkali | Good | |

| Anti-abrasion | Good | |

| Hydrolysis stability | Middle | |

Properties of Woven Fiberglass Filter Bag

| Type | EWTF450 | EWTF550 | EWTF800 | CWTF450 | CWTF550 | |

| Weight (g/m2 ) | 450 | 550 | 800 | 450 | 550 | |

| Tensile strength (N/25mm) | warp | >1750 | >2200 | >2400 | >1700 | >1700 |

| weft | >1000 | >1500 | >2100 | >1900 | >1200 | |

| Permeability(cm/s) | 20~55 | 15~35 | 10~30 | 20~40 | 20~40 | |

| Service temperature(℃) | ≤280 | ≤260 | ||||

| Recommended air flow(m/min) | <0.5 | <0.7 | <0.5 | |||

| Remark | Description include PSI、 FCA、 RH、 BI 、ST,width range 400-1000mm,filter bag diameter rangeΦ120-300mm | |||||

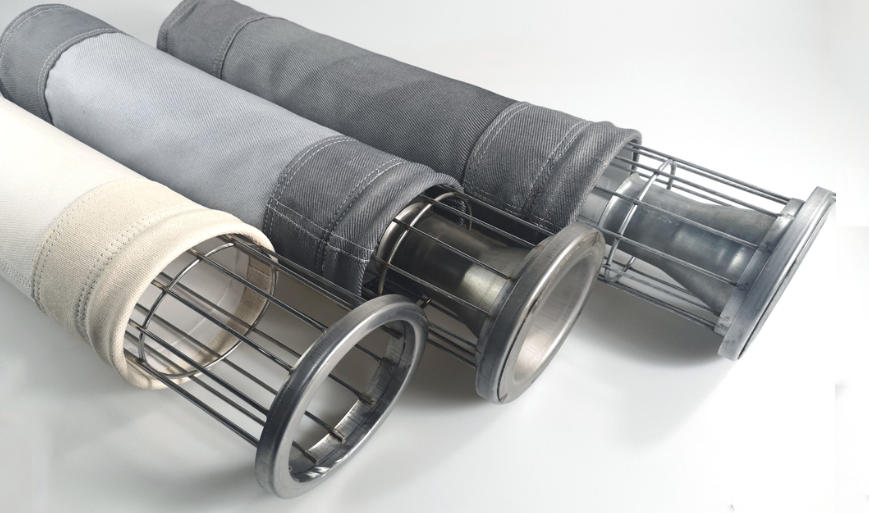

We Pay Attention to Every Processing Detail:

⚫ Accurately design the size of the filter cloth required for the filter bag. The filter cloth will be larger than the actual design size to leave enough operating space.

⚫ Choose the right filter bag accessories and check their quality.

⚫ We draw, cut and sew the filter bags on an automatic production line. When the filter bag needs to be processed manually, we open it on the operating platform and use a certain pulling force to keep it flat.

⚫ We maintain strict processing quality standards in accordance with design drawings and operating procedures. Our workers dress in compliance with safe construction requirements and are prohibited from smoking.