FAP-A-2-40G-M2

Information

| Reference infor. | parameters |

| Size | 1.5 inch |

| Mode | FAP-A-2-40G-M2 |

| Type | threaded with nut / tube |

| Inside sealing | Rubber |

| Use for : | Connecting the pulse valve and tanks |

| Materials | Alminum materials |

| Advantage | connectoring without weld |

| Option size | 3/4G to 2 G |

Trading information

| Trading information | Logistic & delivery information | |||||||

| Name | Qty Piece/Pieces | FOB price USD | Payment terms L/C,,D/P,T/T,Western Union,Paypal |

Min. qty Pieces |

EST. time Day | Seaport | monthly Piece/Pieces |

Packing |

| FAP-A-2-40G-M2 Double Bulkhead connector | < 100 | 8.50 | Payment terms L/C,,D/P,T/T,Western Union,Paypal |

100 | 5 | Shanghai | 10000 | water proof bag and ctns |

| 100-1000 | 7.90 | |||||||

| > 1000 | 7.30 | |||||||

Bulkhead Connectors

Models and Installation

A wall connector consists of an aluminum alloy cast part, stainless punched part and rubber part and is for the connection of inner and outer pipe of airtight containers such as the connection between the blowing tube of pulse jet bag-house and rectangular pulse valve (batten wall mounted) and between submerged electromagnetic pulse valve and outlet pipe (head tank mounted). It can be reliably fixed and sealed without welding and is convenient for installation and maintenance.

A wall connector can keep the gas in the pipe flow freely and effectively seal the container connected to the pipe. But it should not be used to support the parts like the connected pipe and container. The user should take reliable actions to support them.

| Operation pressure | ≤ 0.6 Mpa |

| Operation medium | Clean air |

| Wall crossing thickness | Model A batten wall mounted type---2 to 6mm |

| Lead length for connection | For 1"(25) and 11/2"(40) Model B head tank mounted type----200mm |

| 2’’(50)----- 250mm2 1/2"(62), 3"(76) --- 300mm | |

| Temperature for use | Butyronitrile rubber seal part----- -10~110℃Silicone rubber seal part --------- -35~220℃ |

| Environment for use | Place free corrosive gas |

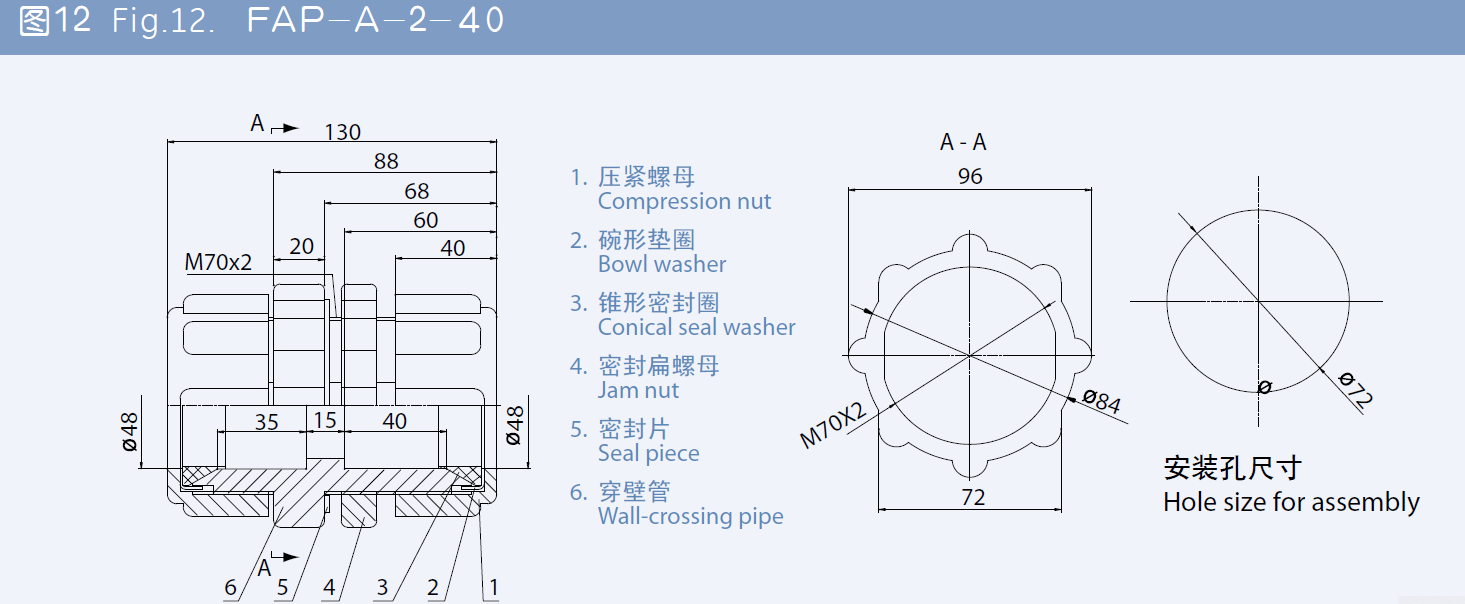

Model

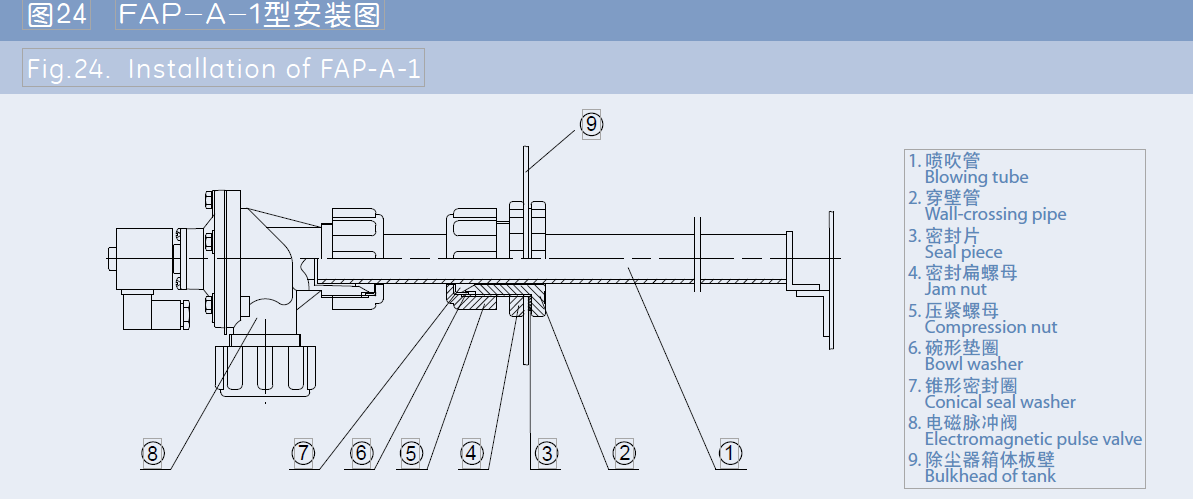

FAP-A-1

Connecting Pulse jet bag-house with removable bag and DMF-ZM series electromagnetic pulse valve below perforated plate

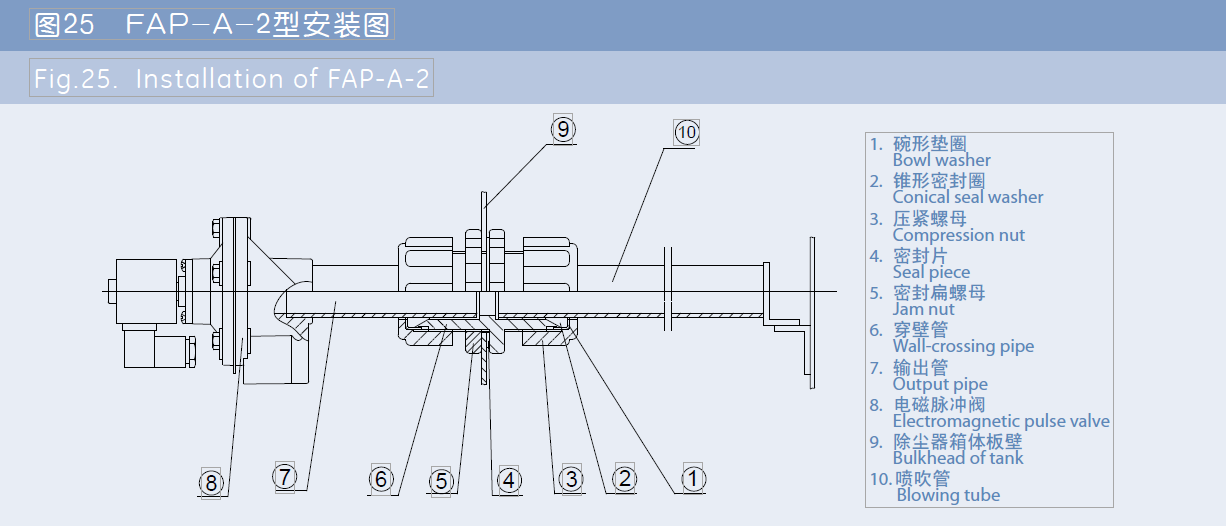

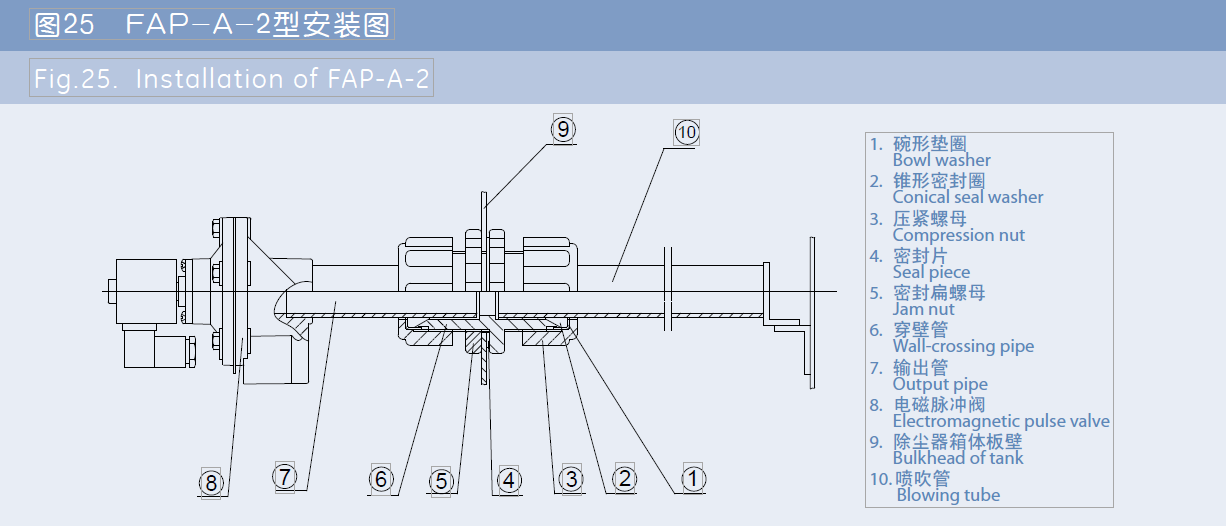

FAP-A-2

Connecting Pulse jet bag-house with removable bag and DMF-Z/ZM series electromagnetic pulse valve above perforated plate.

FAP-A-2

Connecting Pulse jet bag-house with removable bag and DMF-Z/ZM series electromagnetic pulse valve above perforated plate.

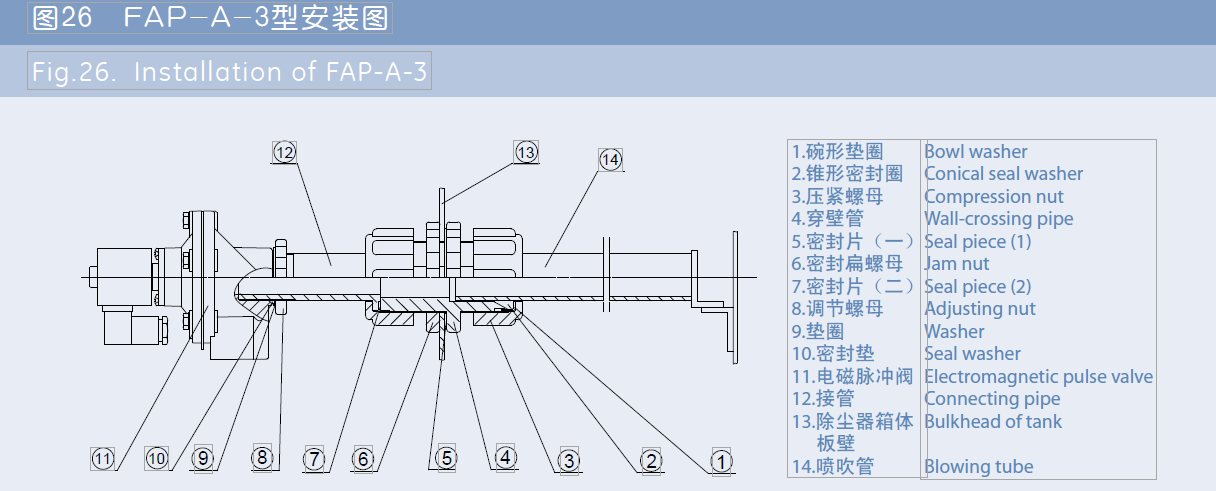

FAP-A-3

Connecting Pulse jet bag-house with removable bag and DMF-ZM series electromagnetic pulse valve above perforated plate.

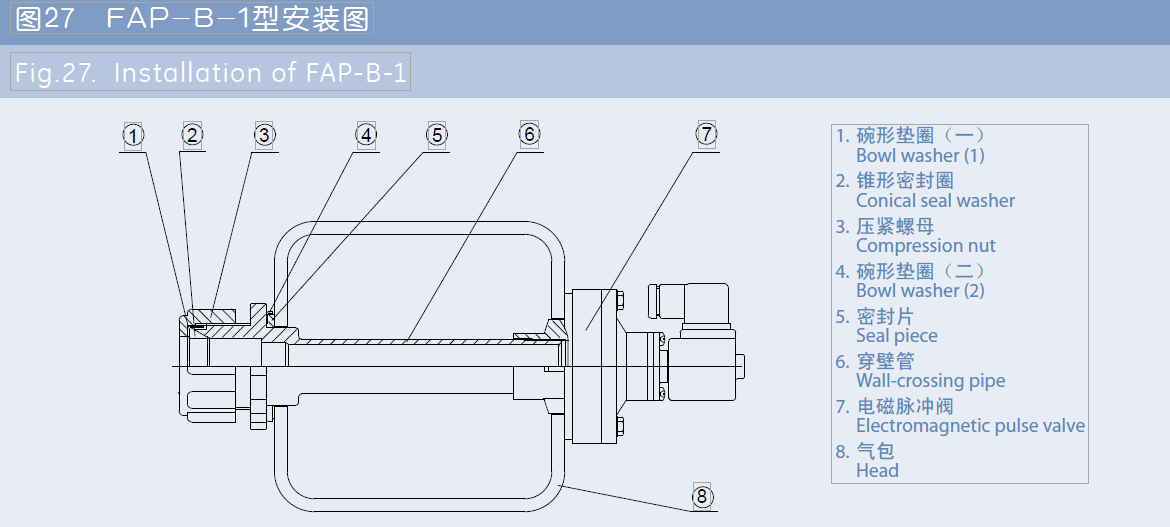

FAP-B-1

Square head and DMF-Y series electromagnetic pulse valve (thread connection)

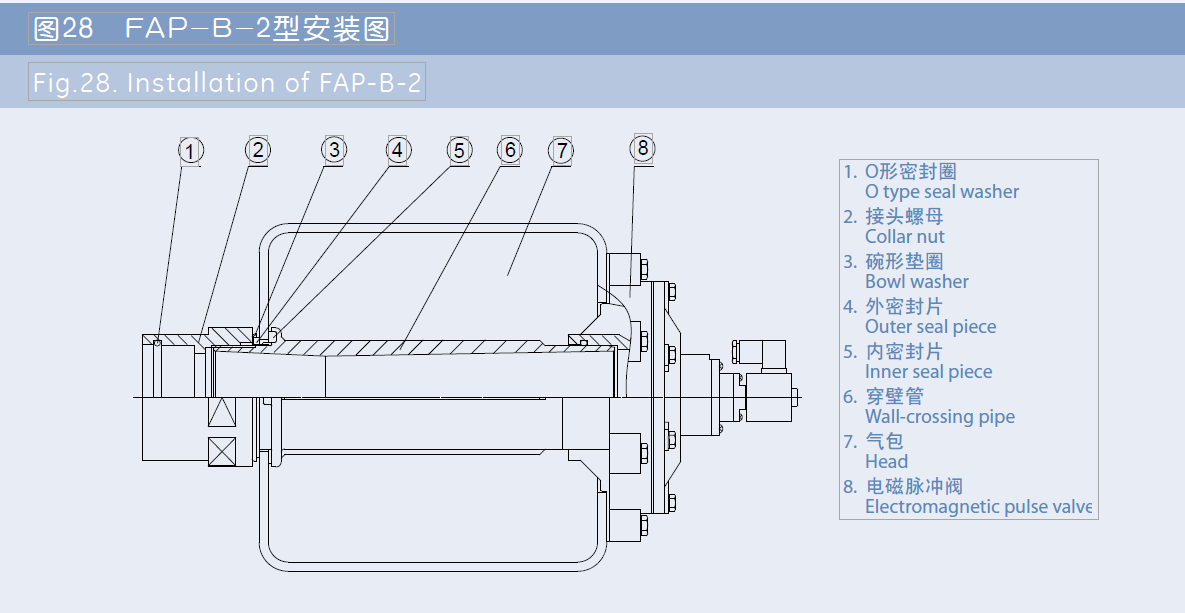

FAP-B-2

Square head and DMF-Y series electromagnetic pulse valve (slip connection)

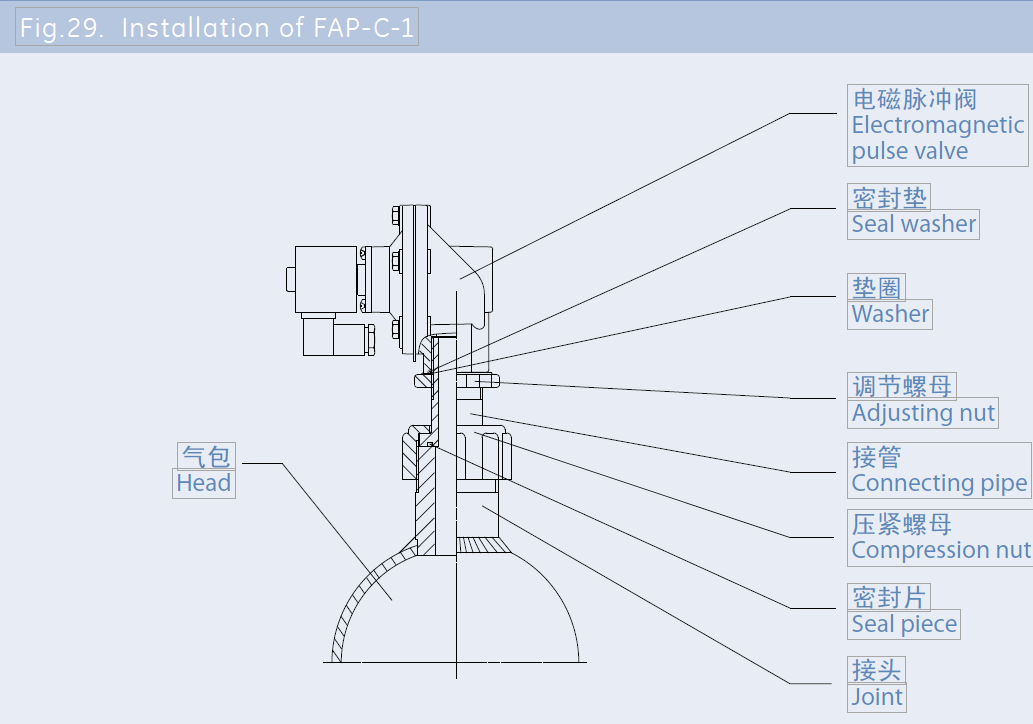

FAP-C-1

Round head and the outlet end of DMF-Z series electromagnetic pulse valve

Installation

See Figures 24~29 for installation of various models of wall connectors, which are for user’ s reference and are subject to change as per the actual application. When installing them, users should pay attention to the following points:

The sizes of the hole in the batten wall or the head tank should be proper. Too small sizes are not convenient for installation and may result in the threads’ damage. Too large sizes will affect the seal and location.

Locate the parts properly in their installation, especially the seal piece. Otherwise, the airtight property will be affected.

The producer has applied the sealing-glue (it is effective after several times of dismantling and installing) on the threads that need to be sealed when the product is delivered. Properly tighten the parts may ensure the seal.

When installing the slip head wall connector, properly apply the lubricant before putting the wall-crossing pipe through the valve’s seal washer for convenient installation.

There should not be any substance between threads. Apply the lubricant if necessary. Tighten the crossing pipe and nut properly to avoid any damage to threads.

Sizes for options

| 3/4’’ | 20G | FAP-A-1-20G-M2 |

| 1’’ | 25G | FAP-A-1-25G-M2 |

| 1.5’’ | 40G | FAP-A-1-40G-M2 |

| 2’’ | 50G | FAP-A-1-50G-M2 |

| 3/4’’ | 20G | FAP-A-2-20G-M2 |

| 1’’ | 25G | FAP-A-2-25G-M2 |

| 1.5’’ | 40G | FAP-A-2-40G-M2 |

| 2’’ | 50G | FAP-A-2-50G-M2 |

| 3/4’’ | 20G | FAP-A-3-20G-M2 |

| 1’’ | 25G | FAP-A-3-25G-M2 |

| 1.5’’ | 40G | FAP-A-3-40G-M2 |

| 2’’ | 50G | FAP-A-3-50G-M2 |

| 1’’ | 25G | FAP-B-1-25G-M2 |

| 1.5’’ | 40G | FAP-B-1-40G-M2 |

| 2’’ | 50G | FAP-B-2-50G-M2 |

| 2.5’’ | 62G | FAP-B-2-62G-M2 |

| 3’’ | 76G | FAP-B-2-76G-M2 |

| 3/4’’ | 20G | FAP-C-1-20G-M2 |

| 1’’ | 25G | FAP-C-1-25G-M2 |

| 1.5’’ | 40G | FAP-C-1-40G-M2 |

| 2’’ | 50G | FAP-C-1-50G-M2 |