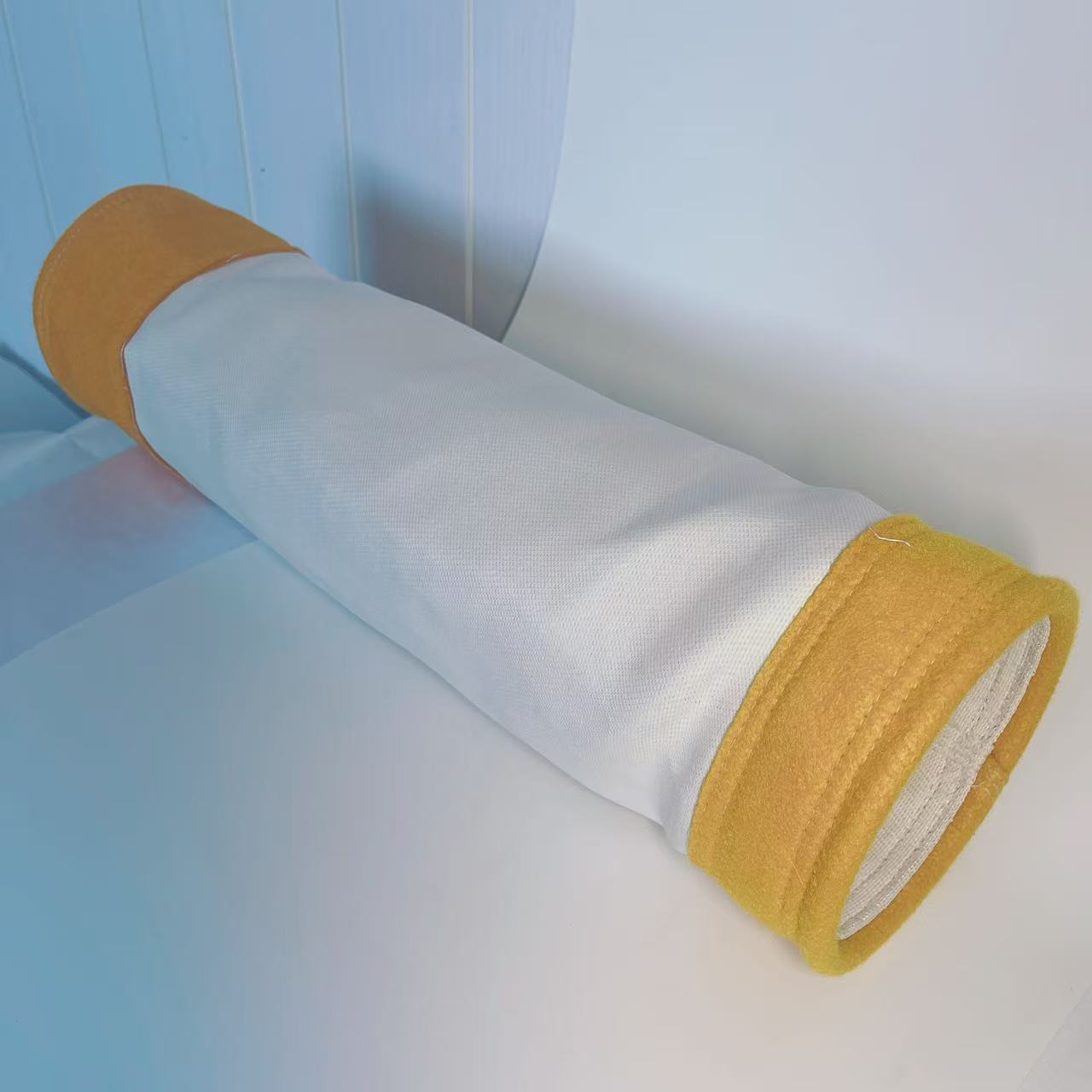

Dust Filter bag

-

FILTER CLOTH :WOVEN-FIBER GLASS w PTFE Membrane

we have polyester and high temperature resistance filter sleeve/filter bagsneedle felt, punch felt, singe, calendaring, heat settingTypes:Anti-static, water&oilresistance, PTFE membrance

item Standard Parameter value AREA WEIGHT(面积重量) EN12127 750±22.5g/m²(19.08±0.65oz/yd²) THICKNESS(厚度) EN ISO 9073/2 0.7-1.1mm(0.027–0.043in) WEAVE(编织方式) — DOUBLE TWILL(双斜纹) FINISH(后整理) — PTFE MEMBRANE(覆 PTFE 膜) TENSILE STRENGTH(拉伸强度,5×20cm) GB/T 3923.1-2013 ≥3400N(另有≥2400N 未明确标准) ELONGATION(伸长率) GB/T 3923.1-2013 ≤8% THERMAL STABILITY(热稳定性,260℃ 2h 收缩率) GB/T 6719-2009 ≤1.5%(另有≤1% 未明确标准) AIR PERMEABILITY(透气率,200Pa) GB/T 5453 12-54 l/dm²min OPERATING TEMPERATURE(工作温度,干燥) — CONTINUOUS(连续):260℃Max(500℉Max)

PEAKS(峰值):280℃Max(536℉Max)Please contact us if necessary

-

Environmental defender:PTFE filter bag

Details about PTFE filter bag finishing:

First, material characteristics

High temperature resistance: continuous operation at 240 ° C, instant resistance to 260 ° C high temperature.

Corrosion resistance: Almost all acid and alkali resistance, organic solvents and chemical corrosion, chemical stability is very high.

Low friction coefficient: smooth surface, good self-moistening, not easy to adhere to impurities, easy to clean.

Other characteristics: UV resistance, no moisture absorption, but the wear resistance is general, the filter bag frame requires high finish.

2. Technical parameters (Take mainstream products as an example)

Fiber/substrate: 100% PTFE

Square gram weight: 750g/m²

Thickness: 1.1mm

Air permeability: 90-100L/㎡·min

Fracture strength: longitudinal and transverse ≥450N/5cm

Thermal shrinkage rate: 3% shrinkage at 260℃ for 90 minutes

Continuous operating temperature: 240℃, instant temperature 260℃

3. Application fields

Industrial flue gas treatment: coal-fired boilers, waste incineration, carbon black production, titanium dioxide production, etc.

Chemical industry: Filter acids, alkalis, solvents and corrosive chemicals.

Pharmaceutical and Food: Purification of pharmaceuticals, clarification of beverages/dairy products, solid-liquid separation in food processing.

Environmental protection: sewage treatment, waste gas treatment, air purification.

Electronics industry: high purity gas/liquid filtration, clean room air purification.

Other: petrochemical, paint, ink, resin production, etc.

4. Analysis of advantages and disadvantages

Advantages:

Chemical stability and high temperature resistance in extreme environments.

High filtration accuracy (up to 0.1-100 microns), high efficiency.

Long service life, relatively low maintenance costs.

Cons:

The cost is high and the initial investment is large.

Poor wear resistance, pay attention to the filter bag frame finish.

Five, use and installation precautions

Before installation:

Check whether the filter bag is damaged and clean the surface of dust and impurities.

Make sure the filter bag fits the frame tightly to avoid leaks.

In use:

Control the temperature below 260 ° C to avoid high temperature deformation.

Prevent the impact of high-speed air flow, reduce the vibration damage of filter bag.

When dealing with low temperature and high humidity gas, anti-condensation measures (such as heating and dehumidifying) are required.

Maintenance:

Check the wear of the filter bag regularly and replace it in time.

Use an electric vacuum cleaner and avoid washing.

Keep dry and ventilated when storing away from direct sunlight. -

The following are successful application cases of dust filter bags in different industries

The following are successful application cases of dust filter bags in different industries, demonstrating their efficient dust removal performance and environmental value:

1. Mining industry: efficient control of dust pollution

Iron ore crushing section: a large mining enterprise in the crushing and screening links to introduce cloth bag dust collector, through the needle felt filter bag to capture fine dust, dust emission concentration is reduced to the national standard, improve the working environment, reduce the risk of occupational diseases.

Gold mine tailings treatment: gold mine enterprises use customized filter bags to treat the dust in the tailings transportation, combined with the pulse ash cleaning system, dust capture rate of more than 99%, effectively protect the surrounding ecological environment, enhance the enterprise environmental protection image.

2. High temperature industry: cope with complex conditions

Glass manufacturing: A glass factory uses coated PTFE needled felt filter bags to treat high temperature flue gas (260 ° C), which not only achieves dust emission concentration below 10mg/m³, but also reduces the filter bag replacement frequency and reduces maintenance costs by 30%.

Coal-fired boiler: A power plant uses aramid based filter bag, stable operation in high temperature and high humidity environment, PM2.5 capture efficiency of 99.99%, helping to achieve ultra-low emission goal.

3. Building materials and chemical industry: breaking through technical barriers

Cement factory: Spina felt filter bag developed by a company in Jiangsu improves filtration accuracy through high-pressure water flow process, reducing dust emission from 50mg/m³ to less than 10mg/m³, and increasing material utilization rate by 20%, breaking foreign technology monopoly.

Chemical reactor: A chemical plant uses PTFE coated filter bags to treat the tail gas containing corrosive gases, and the filter bag life is extended to more than 3 years, while achieving efficient recovery of catalyst powder.

4. Agriculture and people’s livelihood: Meet the needs of special scenarios

Straw crushing: The cloth bag energy-saving vacuum cleaner developed by Zhoukou enterprises is applied to the peanut seedling crushing equipment, which completely solves the problem of dust pollution, has been certified by the national patent, and is called “dust removal magic weapon” by farmers.

Cigarette production: A cigarette factory in Chongqing has extended the replacement cycle of the filter bag by 50% by reforming the anti-clogging device of the pressure differential meter pressure tube combined with the anti-corrosion filter bag, and the transformation cost of a single set of equipment is only 8 yuan.

5. Environmental technology innovation: intelligent upgrade

Quarry comprehensive application: A quarry in the crushing, screening, transportation links to deploy intelligent bag dust removal system, real-time monitoring of filter bag status through the pressure sensor, combined with AI algorithm to optimize the cleaning cycle, dust concentration reduced by 80%, equipment operating efficiency increased by 25%.

Circular economy practice: An environmental protection company in Xiamen developed a high-temperature silicone sealing process, which increased the service life of the filter bag to 4 years, successfully applied to a number of large projects at home and abroad (such as Turkey waste incineration plant), and the material loss rate was reduced from 2% to 1%.

Sum up

Through material innovation (such as PTFE, arnylon, spina felt) and intelligent design, dust filter bags have achieved significant results in mining, electric power, chemical industry, agriculture and other fields, not only to meet the requirements of environmental regulations, but also to reduce costs and increase efficiency for enterprises. In the future, with the development of filter bag technology in the direction of high precision, long life and intelligence, its application scenarios will be further expanded to help achieve the goal of global carbon neutrality. -

The use of dust filter bag

Dust filter bag is the core component of industrial dust removal system, mainly used to capture and separate dust particles in the air, to ensure the production environment clean and efficient operation of equipment. The following are typical application scenarios and key advantages:

1. Application field

Steel/Metallurgy: electric furnace, blast furnace dust removal, capture metal oxide dust

Chemical: reaction kettle tail gas treatment, filter catalyst powder

Electricity: coal-fired boiler flue gas treatment, to achieve PM2.5 emission standards

Building materials: cement kiln tail dust removal, control particulate emission concentration

Food and medicine: sterile workshop air purification, to ensure the cleanliness of the production environment

2. Core strengths

High efficiency filtration: Using needle felt/film coating process, filtration efficiency of 99.99%

Energy saving and consumption reduction: stable air permeability, reduce the system operating resistance

High temperature resistance: can withstand 260℃ continuous operation (such as glass fiber material)

Long life design: corrosion resistance, wear resistance, life of 2-4 years

Environmental protection features: Support dust recycling, meet the requirements of carbon neutrality

3. Select recommendations

Choose the material according to the working condition: such as PPS for sulfur-containing smoke, PTFE for strong acid environment

Attention to filtration accuracy: sub-micron dust needs to select microporous membrane composite filter material

Matching cleaning method: It is recommended to select filter material with strong folding resistance in pulse cleaning system

4. Maintain key points

Check the damage regularly to avoid powder leakage affecting the system efficiency

Control inlet dust concentration, prolong service life

Clean up the residual dust in time during shutdown to prevent compaction

Modern industrial dust removal systems are developing intelligentiously, some filter bags have integrated pressure sensors, which can monitor the filter status in real time, and optimize the cleaning cycle with AI algorithms to further improve operating efficiency. -

Industrial dust filter bag, all kinds of materials

Unleash Precision Filtration with Our Industrial-Grade Filter Bags!

- Diverse Materials, Unrivaled Performance: Choose from high-quality polyester, nylon, and polypropylene. Each material is engineered to deliver exceptional filtration, whether it’s withstanding harsh chemicals (polypropylene) or providing excellent strength and durability (nylon and polyester).

- Ultra-Precise Filtration: With a wide spectrum of micron ratings available, our filter bags can trap particles of varying sizes. From the tiniest microparticles to larger debris, we’ve got you covered for any filtration need.

- Customizable for Your Convenience: Multiple top options, including ring, drawstring, and flange, ensure a perfect fit for your existing equipment. Tailor the filter bag to your specific setup effortlessly.

- Woven or Felt, Your Call: Our woven and felt materials offer different filtration advantages. Woven bags provide enhanced structural integrity, while felt bags offer higher filtration efficiency. Pick the one that suits your application best.

- Sizes Galore: Available in sizes #1, #2, #3, #4, our filter bags are adaptable to various filtration systems. No matter the scale of your operation, we have the right size for you.

-

Industrial Dust Removal Filter Bag P84 Material with Glass Fiber PTFE Pocket Filter Industrial Dust Filter Bag

Industrial Dust Removal Filter Bag

It is made of P84 material and is equipped with a glass fiber PTFE pocket filter. This is an industrial dust filter bag.Detailed DescriptionOverall Overview

This is an industrial dust removal filter bag that plays a crucial and indispensable role in industrial production scenarios where a large amount of dust is generated, such as cement plants, steel mills, power plants, waste incineration plants, etc. It can effectively capture and filter dust, ensuring that the discharged gas meets environmental protection standards. Meanwhile, it also helps protect production equipment and the working environment.Material Aspects- P84 Material: P84 fiber is a high-performance synthetic fiber with excellent high-temperature resistance. It can generally be used continuously at a high temperature of 260°C, and it can even withstand higher temperatures instantaneously. It also has outstanding chemical stability and can resist the erosion of a variety of chemical substances, showing good tolerance to corrosive gases and liquids such as acids and alkalis. Moreover, P84 fiber has a high filtration efficiency, which can effectively intercept and capture dust particles of various particle sizes, providing a reliable guarantee for industrial dust removal.

- Glass Fiber: Glass fiber features high strength and high modulus, which can enhance the overall mechanical properties of the filter bag, making it more robust and durable, and less prone to damage. At the same time, glass fiber also has a certain degree of high-temperature resistance. When used in combination with P84 material, it further improves the stability and reliability of the filter bag in high-temperature environments.

- PTFE: Polytetrafluoroethylene (PTFE) has an extremely low surface energy, which makes it difficult for dust to adhere to the surface of the filter bag. The dust can be easily removed by the dust cleaning system, thus ensuring the filtration performance and service life of the filter bag. PTFE also has excellent chemical stability and weather resistance, and can maintain stable performance in various harsh industrial environments.

Structural Features- Bag Filter: It adopts a bag structure, which has a large filtration area and can handle a large amount of dusty gas per unit time. The filter bag is usually cylindrical or oval in shape, with one end closed and the other end open. The open end is connected to the pipeline or box of the dust removal equipment. The dusty gas enters the filter bag from the open end. After being filtered by the filter material, the dust is intercepted on the inner surface of the filter bag, and the purified gas is discharged through the pores of the filter bag.

- Pocket Filter (Bag-in-bag Structure): The so-called bag-in-bag structure means that some small bag-shaped structures are set inside the large filter bag. These small bags can further increase the filtration area and improve the filtration efficiency. At the same time, the design of the small bags can also make the distribution of dust more uniform during the filtration process, reduce the accumulation of dust in local areas, and improve the overall performance of the filter bag.

In general, this industrial dust removal filter bag can play an efficient and stable filtering role in the field of industrial dust removal, providing strong support for the environmental protection and sustainable development of industrial production. -

Working Principles of Dust Collection Equipment Filter Bags

Dust collection equipment filter bags operate through the combined action of multiple principles to achieve efficient purification of dusty gases:1. Sieving Effect

The filter bag functions like a sieve with a specific pore size. When dusty gas passes through, dust particles larger than the pore size of the filter bag cannot penetrate and are directly intercepted on the surface of the filter bag. For example, in some wood – processing workshops, large wood chips are intercepted by sieving.2. Inertial Impaction

When the dusty gas stream passes through the filter bag, the direction of the gas flow changes. Larger – mass dust particles, due to inertia, cannot change direction in time along with the gas flow and will collide with the fibers of the filter bag and be captured. In steel mills, during the high – temperature smelting process, large – sized dust particles are intercepted by inertial impaction when the gas passes through the filter bag.3. Interception Effect

Some dust particles slightly smaller than the pore size of the filter bag, when brought close to the filter bag fibers by the gas flow, will be directly intercepted by the fibers. It’s similar to how small objects in a narrow passage are easily blocked by obstacles beside them.4. Diffusion Effect

For extremely fine dust particles, they will perform irregular Brownian motion under the influence of the thermal motion of gas molecules, which increases the chance of contacting and being adsorbed by the filter bag fibers. In chemical production, some fine dust is captured by the filter bag through the diffusion effect.5. Electrostatic Adsorption

Some filter bag materials generate static electricity during friction with dust, or they already carry static electricity. Dust particles will be adsorbed onto the filter bag due to electrostatic attraction, enhancing the filtration effect. For example, some filter bags specially used to handle flammable dust often utilize the principle of electrostatic adsorption to improve dust removal efficiency.These principles work in concert, enabling the filter bags of dust collection equipment to effectively purify dusty gases, ensuring a clean production environment and the normal operation of equipment. -

Industrial filter bag efficient dust removal, factory custom

Industrial filter bag, dust filter, liquid filter bag, high temperature filter bag, customized filtration solution, environmental protection filtration equipment

Industrial filter bag has the characteristics of high strength, acid and alkali corrosion resistance, wear resistance, folding resistance, easy to clean ash, water repellant oil, anti-static and so on. Application: Industrial filter bags are widely used in steel, cement, chemical industry, power plants, road construction, metallurgy, grain processing, electronics, tobacco and other environmental protection projects

-

Why choose our industrial filter bags?

Why choose our industrial filter bags

** Super durability ** : Select high temperature resistance, corrosion resistance materials (such as polyester, polypropylene, PTFE), to adapt to acid, high temperature, high pressure environment, life extension of more than 30%.

✅ ** Multi-scenario adaptation ** : Covering chemical industry, food processing, pharmaceutical, metallurgy, cement, water treatment and other industry needs, tailored filtration solutions.

✅ ** Energy saving ** : low pressure difference design reduces energy consumption, high pollution capacity reduces replacement frequency, and the overall cost drops by 20%.

✅ ** Safety compliance ** : In line with ISO, FDA and other industry standards, non-toxic and pollution-free, to help you easily pass the environmental audit. -

Customized PP PPS and PTFE mixture dust air filter bag

Customized PP PPS and PTFE mixture dust air filter bag

1-5m long for dust removal and filtration matcth bag filter cage

The filter bags produced by our company are designed for harsh industrial environments, using multi-layer composite filter materials and high precision process to effectively intercept micron particles, filtering efficiency of up to 99.9%! Whether it is dust, oil, chemical particles or liquid impurities, it can be easily handled to ensure that the production process is clean and worry-free.

-

Factory dust removal equipment accessories Hot selling products dust removal filter bag

Factory dust removal equipment accessories Hot selling products dust removal filter bag

Polyester needle felt waterproof, oil-proof and electrostatic filter bag.

Our company polyester needle filter felt selection of 1-2.5D polyester fine denier, with high strength and low elongation yarn woven reinforced base cloth, through the needle reinforcement and post-treatment technology. In addition to the characteristics of high porosity, good permeability, acid resistance and moderate alkalinity of ordinary felt filters, the product has very good wear resistance, so it is a variety of felt filters widely used. G weight from 350g/m2-800g/m2, thickness from 1mm-4mm our factory can produce. The post-treatment methods are calendering, singeing, heat setting, impregnation drying, coating and so on. It has the characteristics of stable size, easy cleaning and long service life.The surface smoothness of filter material has a great influence on the dynamic running resistance of filter material. The initial resistance of the filter material is determined by the permeability of the filter material itself, and the resistance in operation is many times larger than the initial resistance. The running resistance depends on the smoothness of the filter surface and the cleaning effect. It is generally hoped that when the filter material ensures the same filtration efficiency, the larger the air permeability, the better, that is, the lower the resistance, the better, because this can save a lot of energy. In the dust collector with air flow back blowing, when the air flow of the same pressure and the same air volume is used for dust removal, the dust removal effect of the woven fabric with high air permeability is better than that of the woven fabric with low air permeability. Therefore, in the case of ensuring the high filtration accuracy of the filter material, how to improve the permeability of the filter material and improve the surface smoothness, reduce dust adhesion, and reduce the operating resistance is the first topic that the filter material manufacturer should study. The air permeability of the surface resinized smooth finishing needled filter felt developed by our factory is more than 50% higher than that of ordinary calender finishing filter material, and the surface smoothness is more smooth than that of calender finishing.

-

High quality Acrylic Filter Bag filter bag for industrial dust removal Industrial Filter Bag Price

High quality Acrylic Filter Bag filter bag for industrial dust removal Industrial

Acrylic Filter Bag filter bag

Our producted manufactures high performance homopolymer acrylic filter bags and provides reliable filtration solutions. Customized sizes are available In addition to the standard sizes.

Material : 100% Acrylic staple fiber.

Scrim: With Acrylic staple yarn.

Length & diameter: No limited.

Weight: 300 -600g/m2 ±10%.

Temperature (℃/℉): Continue: 120/248, Instant: 140/284.

Finish-treatment: Calendering, Heat setting, Singeing.

Anti-acid and alkali: PH ranges from 3-11.

Filtration Efficiency: Reach to 99.5%.

Stable working time: Up to more than 3000 hours. Could be used cyclically.