Anti-Static Needle Felt Cloth

Parameters

| Parameters Representation | ||

| Reference Information | parameters | |

| Product Name | Anti-Static Needle Felt Cloth | |

| Product Code | AASF-PE550 AS Cloth | |

| Physical properties | ||

| Weave method | needle felt | |

| Thickness | 2.0±0.08 | |

| Weight | 550 g/m² | |

| Width | 1.8m-2.1m | customizing |

| Loss on Ignition (%) | ≥10 | |

| Chemical Finish | PTFE coating | Optionally |

| Air Permeability (L/m²S@200Pa) | 30- 80 | |

| Tensile strength( N/5cm ) | Warp | ≥1200 |

| Weft | ≥1300 | |

| Tensile elongation(%) | Warp | ≤35 |

| Weft | ≤50 | |

| Temperature | ||

| Continues temperature | 80 C° | |

| Instant temperature | 120 C° | |

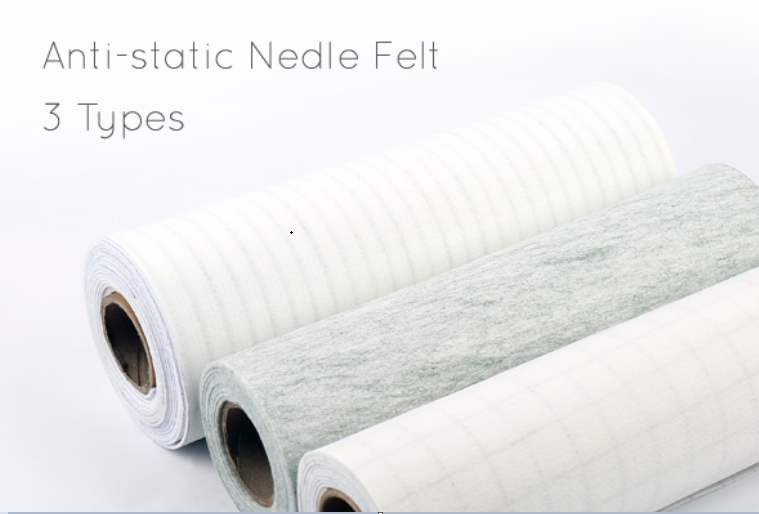

We use leading technology in the Anti-static needle felt and guarantee the stability of our products. Main Anti-static types include blending type, cross type and line type.

Supply Ability: 5000 m2/day

High Filtration Efficiency: Reach to 99.5%

Long Working Life: >3000 hours

Surface Resistance(Ω.cm): 103-108

Anti-static types: Blending type, Cross type, Line type.

Description

Usually, when the concentration of industrial dust reaches a certain level (that is, the explosion limit), it is very easy to cause explosion and fire if it encounters factors such as electrostatic discharge sparks, such as: flour dust, chemical dust, coal dust, etc. If these dusts need to be collected by cloth bags, the manufactured filter bags are required to have anti-static function. In addition to the process of producing ordinary needle felt, the production of antistatic filter material also requires the incorporation of conductive fibers into the warp yarn of the base fabric for the production of needle felt or the mixing of conductive fibers into chemical fibers.

Main Types of Anti-Static Needle Felt

Polyester anti-static needle felt (blending type, cross type and line type).

Aramid anti-static needle felt (blending type, square type, line type).

Note: Various materials of anti-static needle felts you can choose. Accept customization. Let us know your requirement!

Features of Anti-static Needle Felt

Excellent Anti-Abrasion.

Surface resistance(Ω.cm): 103-108

Can be customized.

High quality and economical.

Our Quality

We have a leading technology in the Anti-static Needle Felt, each material must be experimented thousands of times before being put into production. Through these processes, we guarantee the stability of it, and prolong its service life.

Applications

Antistatic needle punched filter felt is mainly used in dust bag products, the main application industries:

Cement raw meal grinding, packaging and transportation links.

Smelters (sintering machines, continuous casting).

Mine (collects limestone powder).

Non-ferrous metal factory (alumina transportation, electrolytic aluminum).

Furniture factory (grinding workshop),

Dust collection for grain processing,

Dust collection in pharmaceutical and other industries.