- Shanghai AASF Technology Co., Ltd.

- fionafu@aasf.com.cn

- +86-021-57658789

Areas of Work

A Viable Cleaning Environment's Method is Air And Solid Filtering.

-

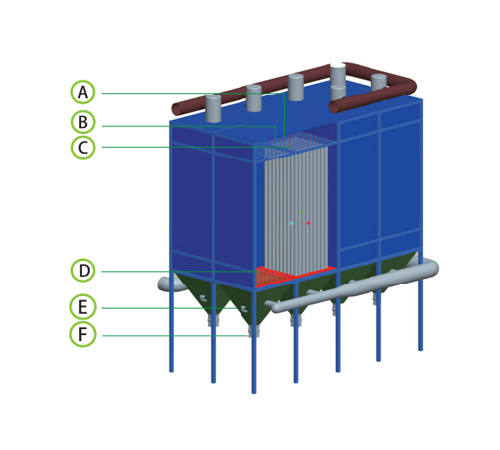

Reverse Blowing Bag Filter

A reverse blowing bag filter is a type of air pollution control device used to remove particulate matter from industrial gas streams. It consists of a series of fabric bags that are suspended vertically in a housing.

-

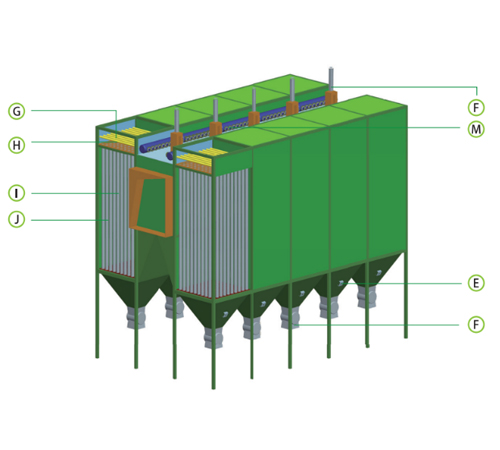

Pulse Jet Bag Filter

The Pulse Jet Bag Filter is commonly used in industries such as cement, steel, power generation, pharmaceuticals, chemicals, and food processing. It is primarily used for air pollution control and dust collection purposes.

-

The Advantage of Our Filter Cloth & Bags

The advantage of our filter bags is very obvious, our filter cloth & bags provide an excellent combination of filtration efficiency and dust cake release. We focus on the premium selection of raw materials and quality controlling. The filter bags enhance flex life and chemical resistance, resulting in long bag performance life. Optimized construction brings the best properties of the filter materials together into a finished product where the strength of the design matches and enhances the strength of the components.

-

Embedded type valves on sale

Valves of this series are directly installed on the air chest (air tank) which is embedded valve, also called immersion valve (also called as injection valve or low pressure valve). During the installation, one should fix the mounting hole on the collar flange of the valve with the air chest through bolts and connects the dust blowing tube with the output port extension tube outside the air chest.

about us

AASF is your best partner who offers complete Solution for Bag Filtration Equipment, a comprehensive package that includes all the necessary components and services for bag filtration systems. It typically includes the bag filter housing, filter bags, filter cartridges, filter media, and any additional accessories required for installation and operation. The solution also includes technical support, maintenance services, and training for the proper use and maintenance of the equipment.

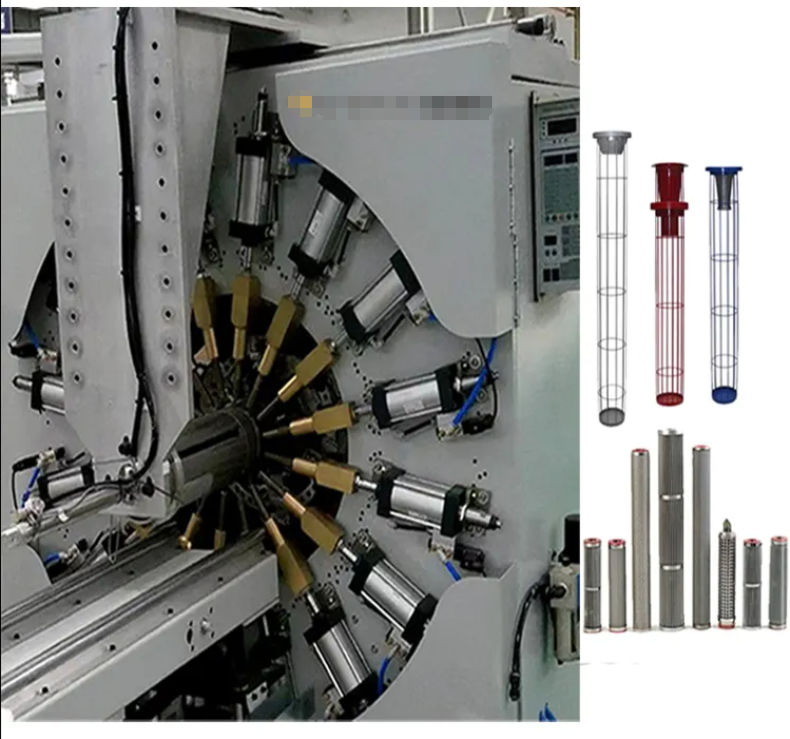

The main products of the Company include electromagnetic pulse valves, pulse jet controllers, bag filters, bag filter cages, special parts, etc. these are wildly used in Cement, Mills, Asphat, Boilers, Chemical processing etc. Our company gains a domestic and global reputation for long time with many loyal customers.

New & Hot Sale

Our innovative filtration technology improves the performance of equipment around the world, we connect the world and make difference for our earth by offering sustainable and financially viable solutions. Cartridge is new product that combine filter media with filter flame together.

With its pleated type, it maximizes the filter area and efficiency.